Metal inter-locked armored fire-and-damp-proof power cable

A technology of interlocking armored and power cables, applied in power cables, power cables with shielding/conducting layers, insulated cables, etc., can solve the problems of core damage, increased use by customers, large traction, etc., to block external signals. The effect of good interference, good shielding of external signals, and good water and moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

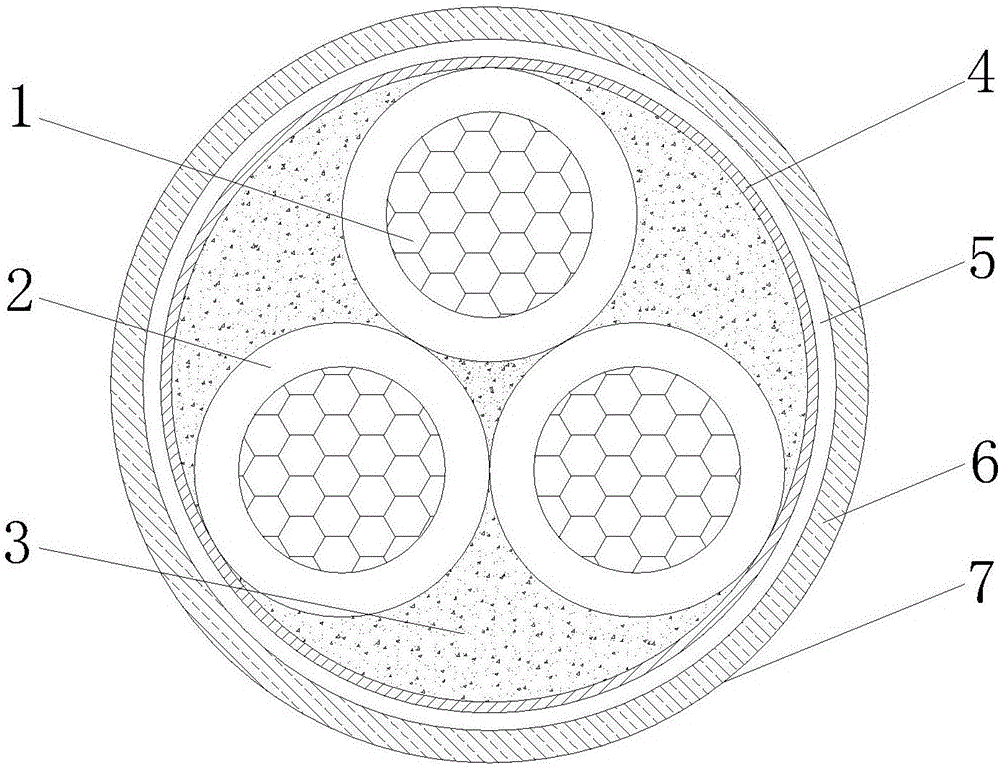

[0015] see figure 1 , an embodiment provided by the present invention: a metal interlocking armored fire-proof and moisture-proof power cable, including a copper conductor 1, a fire-resistant insulating layer 2, a filling layer 3, a double-sided water-blocking layer 4, an interlocking armor layer 5, an outer sheath Cover 6 and cable body 7; cable body 7 is composed of copper conductor 1, refractory insulating layer 2, filling layer 3, double-sided water blocking layer 4, chain armor layer 5 and outer sheath 6, and the cross section of cable body 7 The figure is circular, copper conductor 1 is wrapped with a layer of refractory insulating layer 2, and the diameters between the three refractory insulating layers 2 are equal, and the inside of the double-sided water-blocking layer 4 is wrapped with three refractory insulating layers 2 that are close to each other. And the gap between the double-sided water blocking layer 4 and the refractory insulating layer 2 and the three adjac...

Embodiment 2

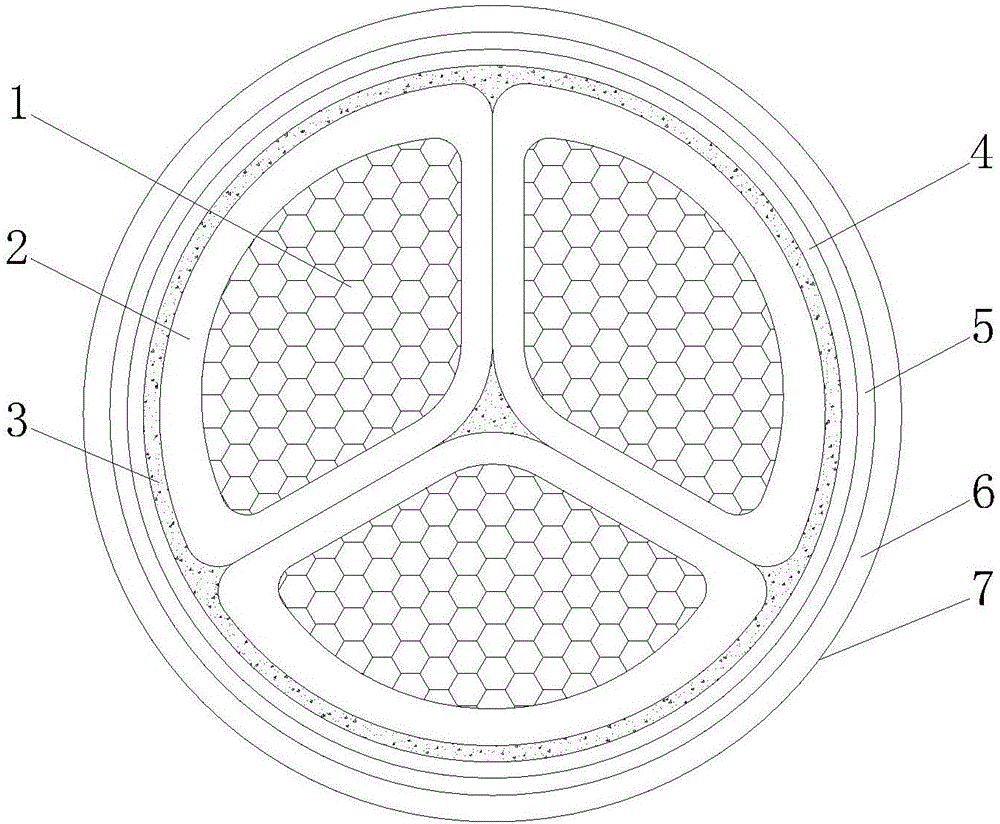

[0018] see figure 2 , an embodiment provided by the present invention: a metal interlocking armored fire-proof and moisture-proof power cable, including a copper conductor 1, a fire-resistant insulating layer 2, a filling layer 3, a double-sided water-blocking layer 4, an interlocking armor layer 5, an outer sheath Cover 6 and cable body 7; cable body 7 is composed of copper conductor 1, refractory insulating layer 2, filling layer 3, double-sided water blocking layer 4, chain armor layer 5 and outer sheath 6, and the cross section of cable body 7 The figure is circular, the copper conductor 1 is wrapped with a layer of refractory insulating layer 2, and the cross-section of the three copper conductors 1 and the three refractory insulating layers 2 is fan-shaped, and the inside of the double-sided water blocking layer 4 is wrapped with a filling layer 3, and the filling layer 3 is composed of polypropylene rope, glass fiber rope and asbestos rope. The filling layer 3 is provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com