A sample carrying platform and a double-beam system electron microscope

A technology of electron microscope and carrying platform, which is applied to circuits, discharge tubes, electrical components, etc., can solve the problems that the imaging effect of scanning electron microscope 7 cannot reach the best, the error between the detected value and the actual value, and the boundary cannot be clearly distinguished. The effect of reducing sample charge accumulation, reducing wear, and clear demarcation line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

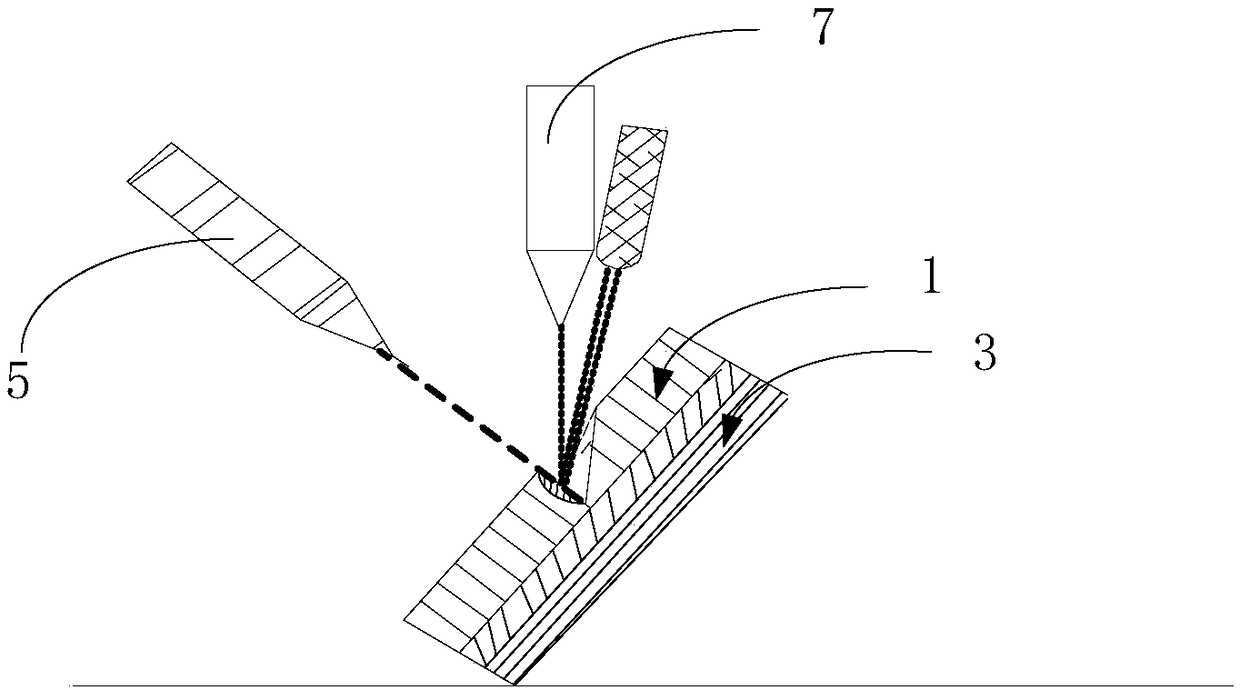

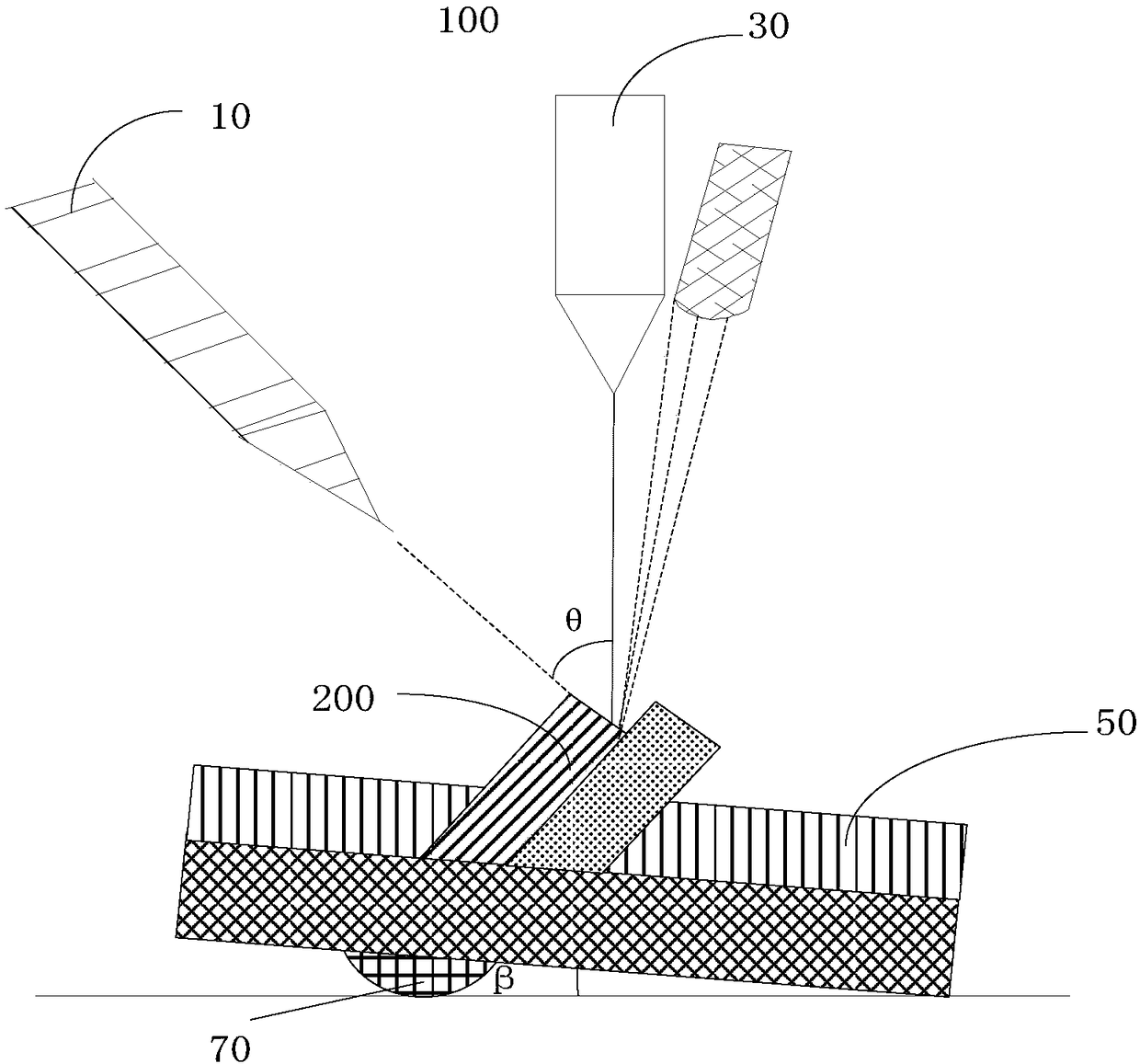

[0038] see image 3 , the present invention provides a dual-beam system electron microscope 100 for taking pictures and scanning the fracture surface of the sample 200 . The double-beam system electron microscope 100 includes an ion cutter 10, an electronic camera 30, a sample carrier 50, and a drive mechanism 70, wherein the ion cutter 10, the electronic camera 30, the sample carrier 50, and the drive mechanism 70 are all arranged in the double-beam system In the vacuum chamber (not shown) of the electron microscope 100 , there is an included angle θ between the cutting direction of the ion cutter 10 and the optical axis direction of the electronic camera 30 , and they both face the sample carrier 50 .

[0039] The ion cutter 10 is used to process the fracture surface of the sample 200 in a direction of flattening the fracture surface of the sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com