Flexible solar cell module and preparation method and application thereof

A technology of flexible solar cells and solar cell sheets, applied in the field of solar cells, can solve the problems of reducing the load of solar aircraft, difficult to adapt to wing fitting, unable to adapt to airfoil curved surface fitting, etc., so as to improve load capacity and flight performance , Improve the effect of pneumatic insurance, and reduce the effect of installation and fixed weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

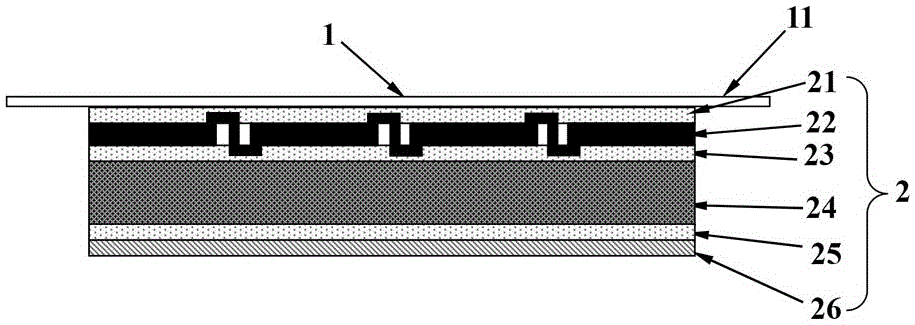

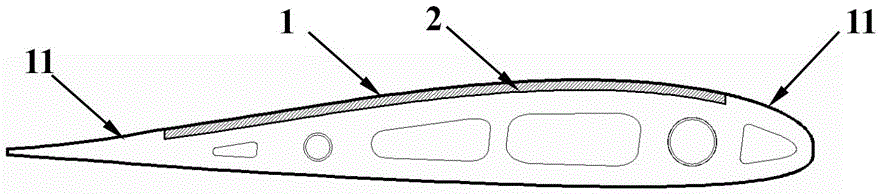

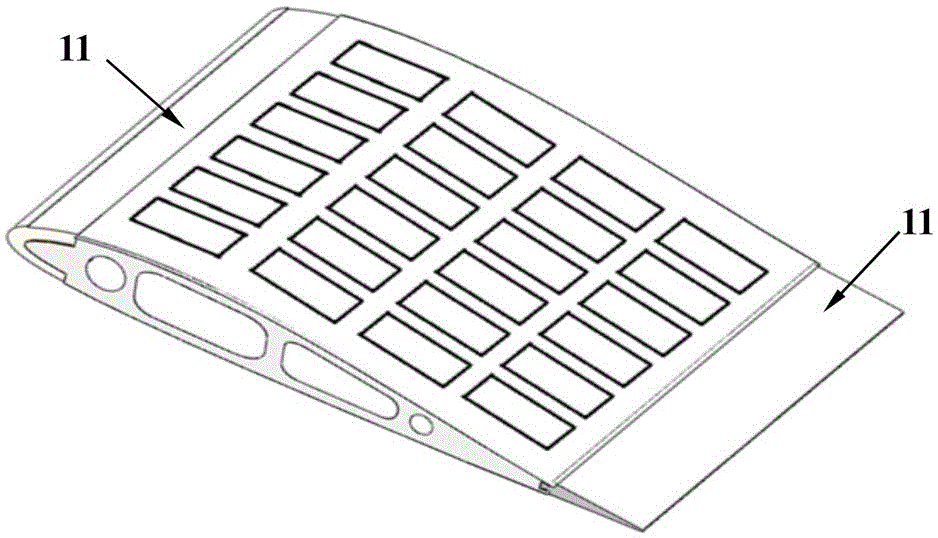

[0037] Such as figure 1 As shown, the flexible solar cell module of this embodiment includes an encapsulation skin 1 and an assembly skeleton 2 disposed on the surface of the encapsulation skin 1 , and the encapsulation skin 1 extends outward along at least one side of the assembly skeleton 2 to form a cladding edge 11 .

[0038] In this embodiment, the encapsulation skin 1 extends upwards to both sides along the span of the aircraft where the component skeleton is laid to form cladding edges 11 .

[0039] In this embodiment, the packaging skin 1 is a PET heat-shrinkable film with a thickness of 25 μm and a transmittance of 95%.

[0040] In other embodiments, the heat-shrinkable film may be PET heat-shrinkable film, PVC heat-shrinkable film, OPS heat-shrinkable film, PE heat-shrinkable film or POF heat-shrinkable film. The thickness of the heat-shrinkable film is preferably 20 μm to 60 μm, and the transmittance is preferably 80% to 100%.

[0041] In this embodiment, the modu...

Embodiment 2

[0058] Such as Figure 4 As shown, the flexible solar cell module of this embodiment includes an encapsulation skin 1 and an assembly skeleton 2 disposed on the surface of the encapsulation skin. The encapsulation skin 1 extends outward along at least one side of the assembly skeleton to form a cladding edge.

[0059] In this embodiment, the encapsulation skin 1 extends upwards to both sides along the span of the aircraft where the component skeleton is laid to form cladding edges.

[0060] Wherein, the packaging skin 1 is a PVC heat-shrinkable film with a thickness of 25 μm and a transmittance of 95%.

[0061] In this embodiment, the module skeleton 2 is arranged on the lower surface of the packaging skin 1, and the module skeleton 2 includes a first packaging adhesive film 21, a flexible solar cell array 22, a second packaging adhesive film 23, and an inner skin 26 from top to bottom. , the third encapsulation film 25 and the support member 24 .

[0062] In this embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com