Manufacturing method for light emitting diode

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of LED photoelectric performance loss, etc., and achieve the effects of reducing failure probability, enhancing firmness, and improving light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

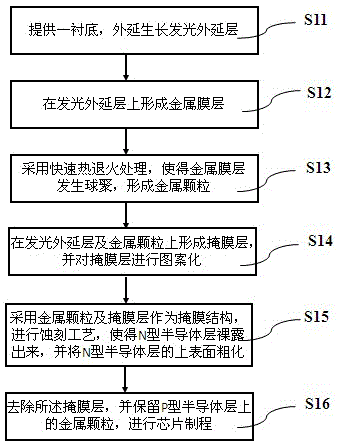

[0033] This embodiment provides a method for manufacturing gallium nitride-based light-emitting diodes. For specific procedures, please refer to figure 1 , including the following process steps:

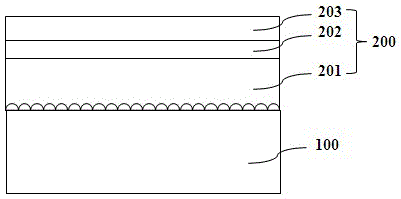

[0034] Step S11, providing a substrate, and epitaxially growing a light-emitting epitaxial layer.

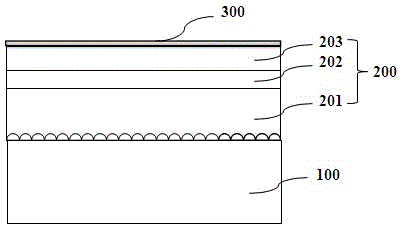

[0035] Step S12, forming a metal film layer on the light-emitting epitaxial layer.

[0036] In step S13 , a rapid thermal annealing treatment is adopted to cause the metal film layer to spheroidize to form metal particles.

[0037] Step S14 , forming a mask layer on the light-emitting epitaxial layer and the metal particles, and patterning the mask layer.

[0038] In step S15 , using the metal particles and the mask layer as a mask structure, an etching process is performed to expose the N-type semiconductor layer and roughen the upper surface of the N-type semiconductor layer.

[0039] In step S16, the mask layer is removed, and the metal particles on the P-type semiconductor layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com