secondary battery

A secondary battery, electrical connection technology, applied in the direction of batteries, battery pack parts, battery caps/end caps, etc., can solve the problems of shortening the service life of the contact piece, excessive heat generation, stress fatigue of the contact piece, etc., to reduce the fire or risk of explosion, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

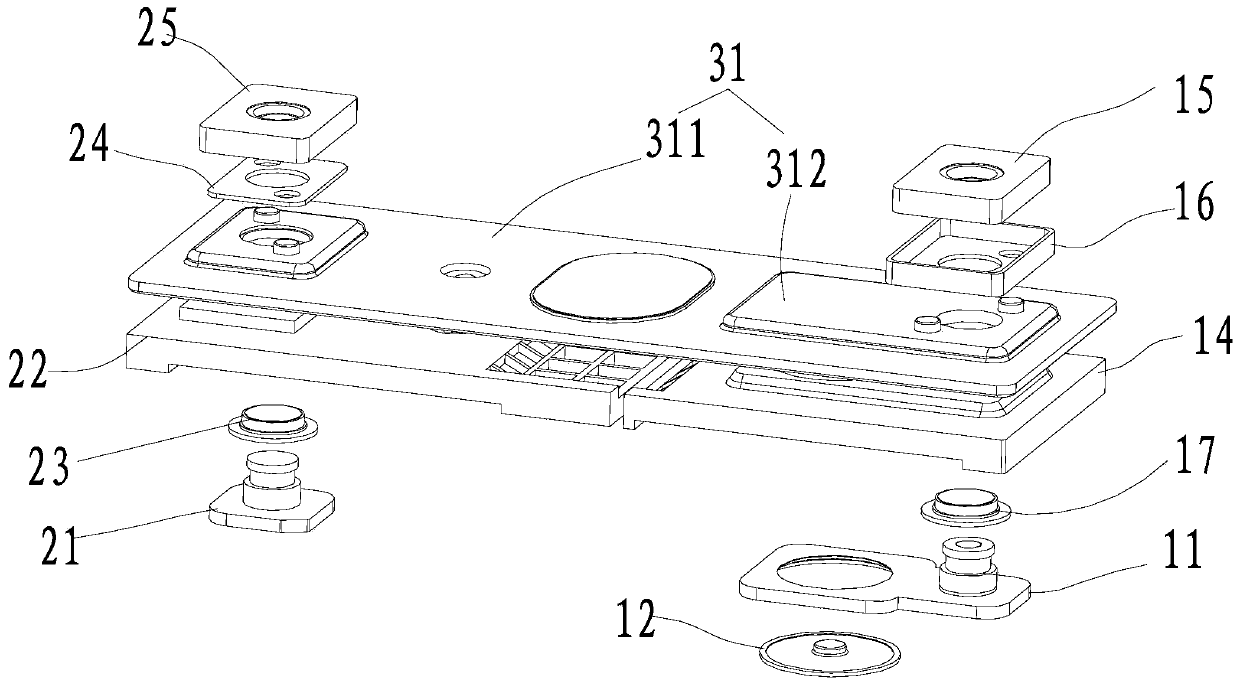

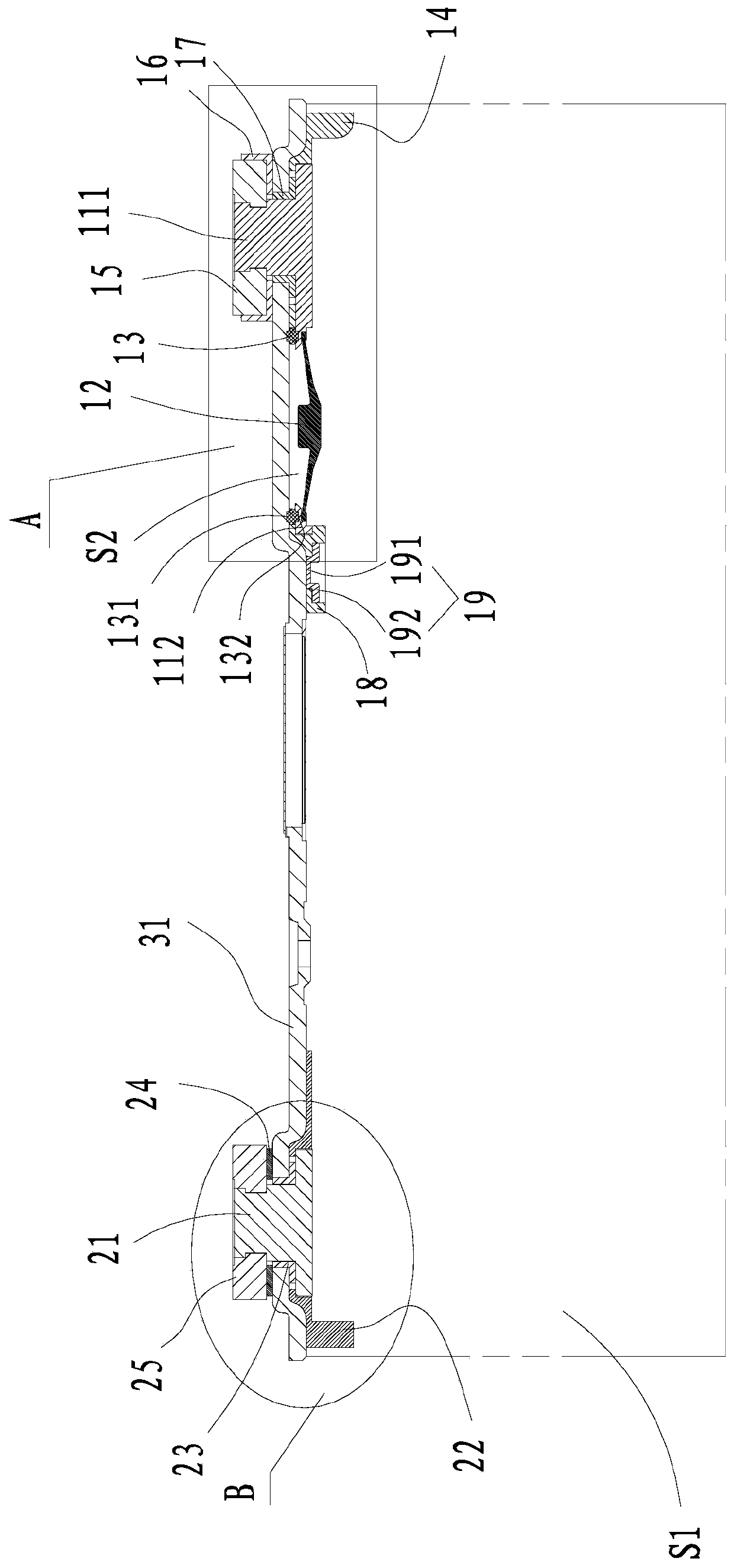

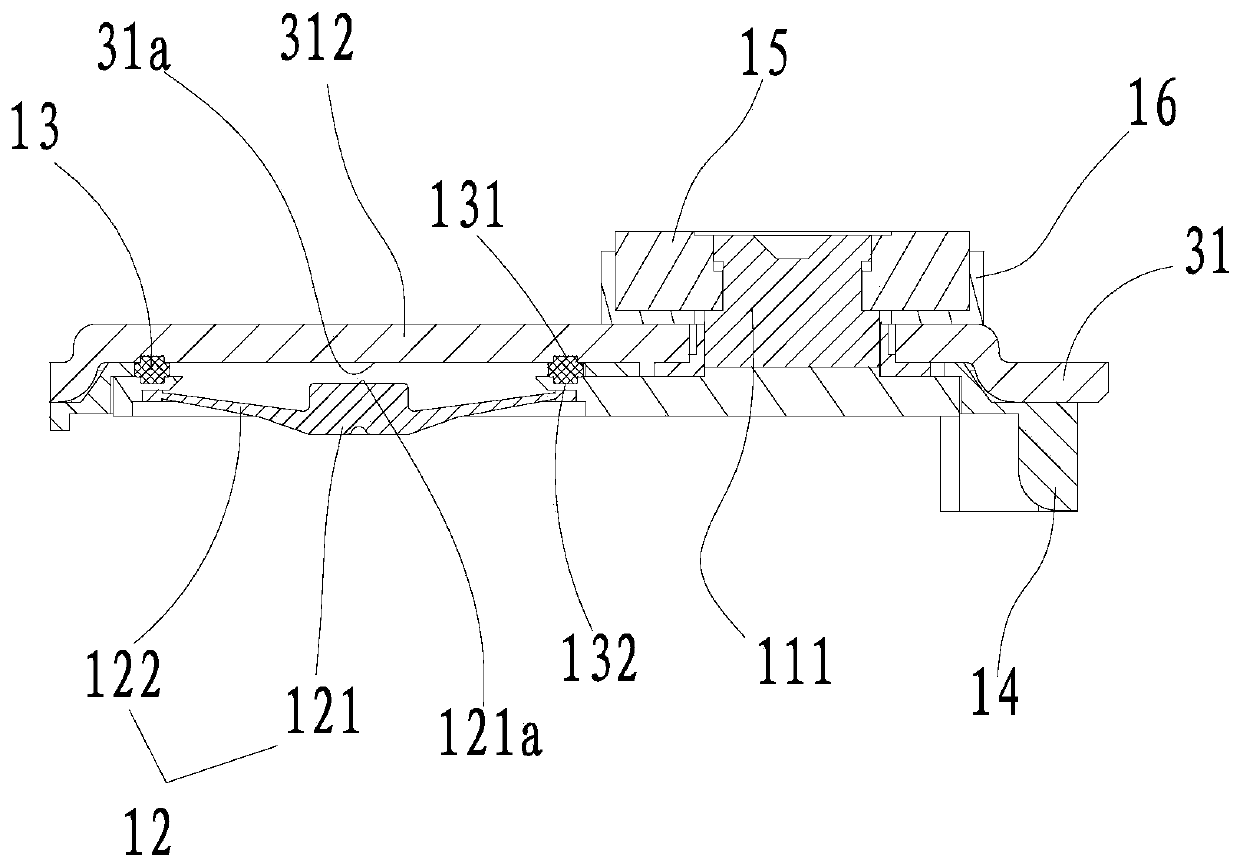

[0106] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings. The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings. The terms "front", "rear", "left", "right", "upper" and "lower" mentioned in the text refer to the placed state of the secondary battery in the drawings.

[0107] Such as Figure 1-9 As shown, the embodiment of the present application provides a secondary battery, the secondary battery includes a first terminal 11 and a second terminal 21, the first terminal 11 and the second terminal 21 can be connected to an external circuit to form a current loop, the secondary battery The battery is used as a power source in the external circuit to output electric energy to the outside world.

[0108] Wherein, the first terminal 11 can be used as a positive terminal, and correspondingly, the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com