Design method for saving space by using high-density connector wafer

A technology that saves space and design method, applied in the field of SI design of server single board, can solve the problems of many holes for reflow and high wiring requirements, and achieve the effect of improving performance, saving PCB space and improving integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

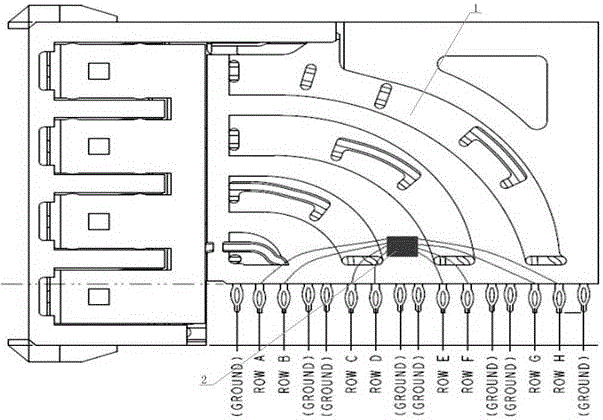

Image

Examples

Embodiment 1

[0022] S1. Select driver chips with different driving capabilities in combination with high-speed link channel performance requirements and cost control requirements;

[0023] S2. Put the driver chip on the connector;

[0024] S3. In combination with link conditions, the long link is turned on and the short link is turned off by software.

[0025] According to product cost control requirements, you can choose to place driver chips with different driving capabilities on the wafer. Connector customization, combined with link conditions, long links need to be driven, and short links do not need to be driven. Control the opening and closing of the number of driver channels through software to achieve performance control and cost control, increase the layout and wiring space of the single board, and meet the design requirements of si for high-speed link performance.

[0026] The driver chip is a repeater (repeater) with pre-emphasis function to improve link driving capability.

Embodiment 2

[0028] S1. Select driver chips with different driving capabilities in combination with high-speed link channel performance requirements and cost control requirements;

[0029] S2. Put the driver chip on the connector;

[0030] S3. In combination with link conditions, the long link is turned on and the short link is turned off by software.

[0031] According to product cost control requirements, you can choose to place driver chips with different driving capabilities on the wafer. Connector customization, combined with link conditions, long links need to be driven, and short links do not need to be driven. Control the opening and closing of the number of driver channels through software to achieve performance control and cost control, increase the layout and wiring space of the single board, and meet the design requirements of si for high-speed link performance.

[0032] The driver chip is a repeater (repeater) with an equalizing function to improve link driving capability. ...

Embodiment 3

[0034] S1. Select driver chips with different driving capabilities in combination with high-speed link channel performance requirements and cost control requirements;

[0035] S2. Put the driver chip on the connector;

[0036] S3. In combination with link conditions, the long link is turned on and the short link is turned off by software.

[0037] According to product cost control requirements, you can choose to place driver chips with different driving capabilities on the wafer. Connector customization, combined with link conditions, long links need to be driven, and short links do not need to be driven. Control the opening and closing of the number of driver channels through software to achieve performance control and cost control, increase the layout and wiring space of the single board, and meet the design requirements of si for high-speed link performance.

[0038] The driver chip is a driver with an equalization function to improve link driving capability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com