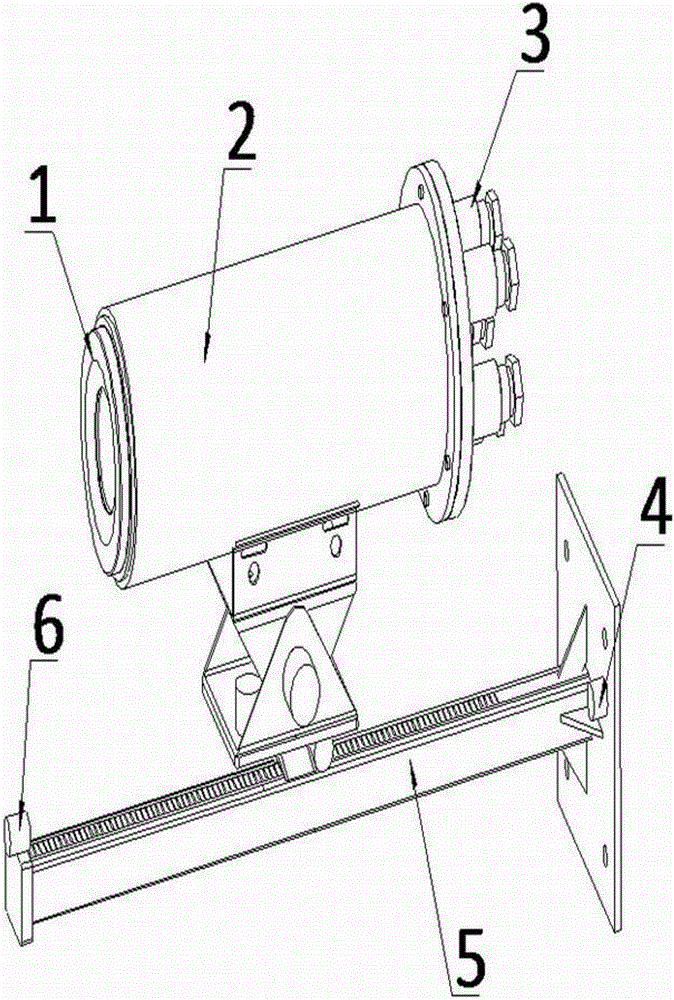

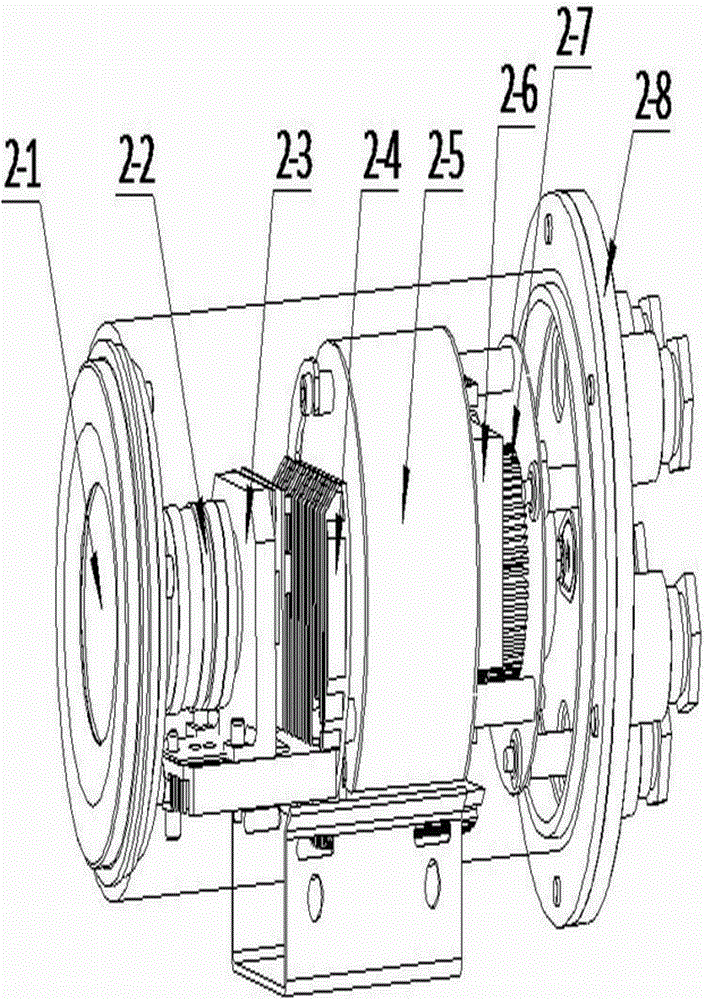

Industrial explosion-proof camera and work method thereof

A camera and industrial technology, which is applied in the field of explosion-proof safety equipment, can solve the problems that the explosion-proof level is difficult to reach IIC level, has few intelligent functions, and cannot be used for explosion-proof requirements, so as to improve imaging effect, wide monitoring range, and increase noise reduction processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

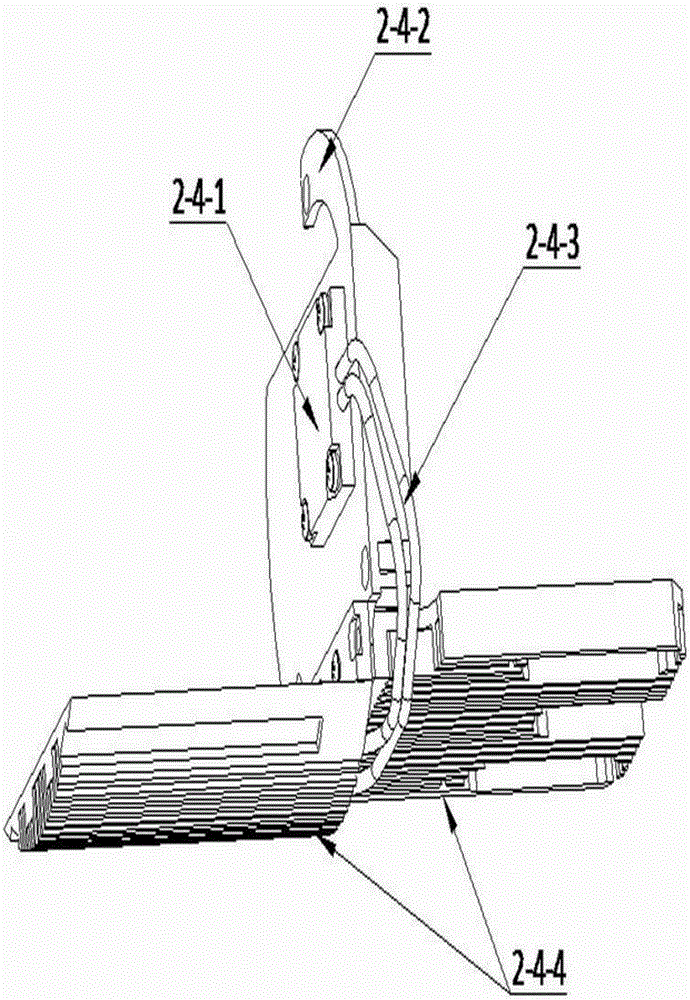

[0056] Manufacture the heat conduction block 2-4-1 of the present invention according to the following steps, and count in parts by weight:

[0057] Step 1: Add 1460 parts of ultrapure water with a conductivity of 3.12μS / cm into the reactor, start the stirrer in the reactor at a speed of 94rpm, start the heating pump, and increase the temperature in the reactor to 72°C; add in sequence 55 parts of 2-ethyl-2-[(2-vinyloxy)methyl]-1,3-propanediol, 1,2-cyclohexanedicarboxylic acid-2-(2-acryloyl)oxyethyl mono 64 parts of ester, (1R)-2,2-dimethyl-3-(2-methyl-1-propenyl)cyclopropanecarboxylic acid-(S)-2-methyl-3-(2-propargyl Base)-4-oxo-cyclopent-2-enyl ester 43 parts, stirred until completely dissolved, adjusted the pH value to 7.8, adjusted the stirrer speed to 124rpm, the temperature was 113°C, and the esterification reaction was carried out for 16 hours;

[0058] Step 2: Take 36 parts of 1-p-(2-methoxyethyl)phenoxy-3-isopropylamino-2-propanol, (1R)-trans-2,2-dimethyl-3- 69 part...

Embodiment 2

[0063] Manufacture the heat conduction block 2-4-1 of the present invention according to the following steps, and count in parts by weight:

[0064] Step 1: Add 2680 parts of ultrapure water with a conductivity of 6.45μS / cm into the reactor, start the stirrer in the reactor at a speed of 153rpm, start the heating pump, and raise the temperature in the reactor to 106°C; add in sequence 2-Ethyl-2-[(2-vinyloxy)methyl]-1,3-propanediol 102 parts, 1,2-cyclohexanedicarboxylic acid-2-(2-acryloyl)oxyethyl mono 132 parts of ester, (1R)-2,2-dimethyl-3-(2-methyl-1-propenyl)cyclopropanecarboxylic acid-(S)-2-methyl-3-(2-propargyl Base)-4-oxo-cyclopent-2-enyl ester 92 parts, stirred until completely dissolved, adjusted the pH value to 9.2, adjusted the stirrer speed to 195rpm, the temperature was 176 ° C, and the esterification reaction was carried out for 34 hours;

[0065] Step 2: Take 84 parts of 1-p-(2-methoxyethyl)phenoxy-3-isopropylamino-2-propanol, (1R)-trans-2,2-dimethyl-3- 136 par...

Embodiment 3

[0070] Manufacture the heat conduction block 2-4-1 of the present invention according to the following steps, and count in parts by weight:

[0071] Step 1: Add 2060 parts of ultrapure water with a conductivity of 4.25μS / cm into the reactor, start the stirrer in the reactor at a speed of 124rpm, start the heating pump, and raise the temperature in the reactor to 87°C; add in sequence 76 parts of 2-ethyl-2-[(2-vinyloxy)methyl]-1,3-propanediol, 1,2-cyclohexanedicarboxylic acid-2-(2-acryloyl)oxyethyl mono 94 parts of ester, (1R)-2,2-dimethyl-3-(2-methyl-1-propenyl)cyclopropanecarboxylic acid-(S)-2-methyl-3-(2-propargyl Base)-4-oxo-cyclopent-2-enyl ester 66 parts, stir until completely dissolved, adjust the pH value to 8.5, adjust the stirrer speed to 160rpm, the temperature is 143 ° C, and the esterification reaction is 24 hours;

[0072] Step 2: Take 61 parts of 1-p-(2-methoxyethyl)phenoxy-3-isopropylamino-2-propanol, (1R)-trans-2,2-dimethyl-3- 95 parts of (2-methyl-1-propenyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com