Printable and sinterable dental compositions for producing parts of dental prostheses and method for producing same

A composition, dental technology, applied in the direction of additive processing of mixtures of solid materials and liquid materials, dentistry, dental prostheses, etc., can solve the problems of expensive, consumption, large materials, etc., to achieve the effect of promoting cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0121] Ink: An ink is prepared by mixing components (i), (ii) and (iii) with each other, the total amounting to 100% by weight. To prepare homogeneous dispersions, the samples were post-treated in an ultrasonic bath.

[0122] (i) filler in ink:

[0123] a) with 3mol-% Y 2 o 3 Stabilized zirconium dioxide; 15 wt.-% (Example 1)

Embodiment 8

[0131] Particle size: a) about 0.7μm, d 90 = 1.3 μm, d 99 <1.9μm

[0132] b) to f)d 50 Less than or equal to 500nm, d 90 Less than or equal to 1.0μm

[0133] g)d 50 =560nm,d 90 Less than or equal to 1.0μm

[0134] a) to g) sample viscosity 40-15mPas

[0135] (ii) Liquid components:

[0136] Water: 20-55wt.-%

[0137] Ethanol: 10-30wt.-%

[0138] Ethylene glycol: 5-40wt.-%

[0139] (iii) Excipient dispersant / liquefaction agent: 0.2 wt.-% Dolapix CE 64.

Embodiment 9 and 10

[0141] Table 1a: Ink composition

[0142]

[0143] Table 1b: Ink composition

[0144]

[0145] 1 Particle size distribution is the same as embodiment 1-8

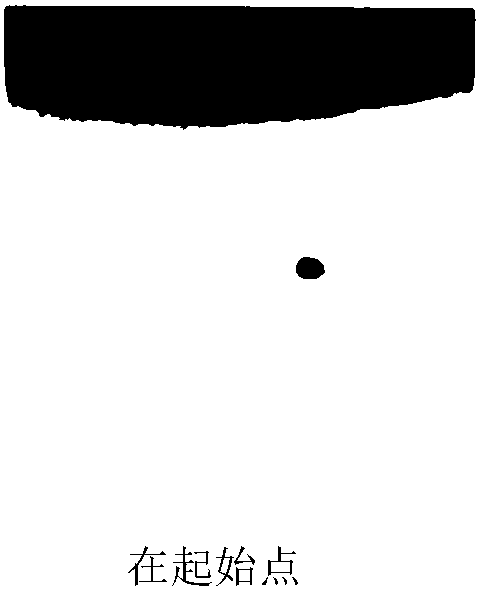

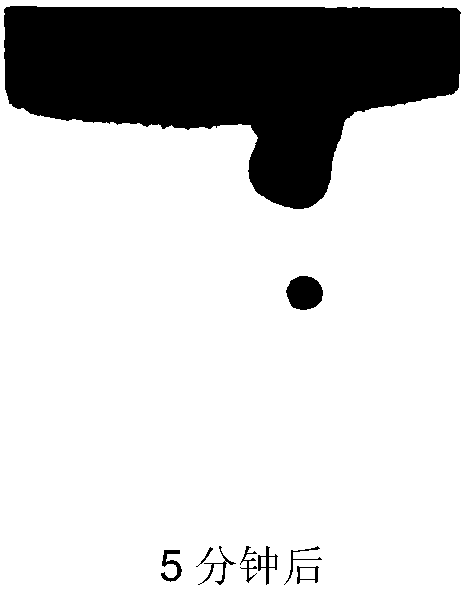

[0146] Ink and droplets exhibit sufficient stability during printing ( Figure 1a and b; droplet settings: voltage / pulse intensity 58 / 28, frequency 500 Hz after about 5 minutes, droplet size about 48 μm). Dental ceramic fillers in ink (powdered components): d 50 =4.6μm,d 100 = 17 μm.

[0147] Table 2: Dental inks and fillers in powder beds, by weight percent (composition material SiO 2 Raw materials: A3, A2, A1)

[0148]

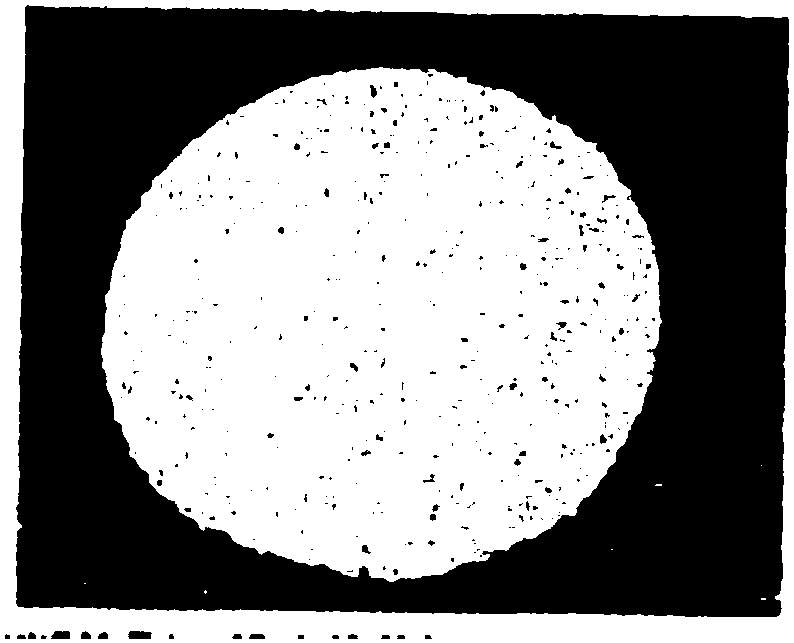

[0149] Powder bed (table 3): with 3mol-%Y 2 o 3 Stabilized Flowable Dental Ceramic Powder Zirconia

[0150] Table 3: Powder Bed Samples 1 and 2 Dental Ceramic Powders - Zirconia

[0151] sample 1 2 – silanized composition ZrO 2 ,3mol-%Y 2 o 3

ZrO 2 ,3mol-%Y 2 o 3

d 50

0.7μm 0.7μm Bulk density: [g / cm 3 ]

3.61 3.33 Angle of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com