Method and device for filling level detection in a cylinder of a combustion engine

An internal combustion engine and cylinder technology, applied in electrical control, mechanical equipment, engine control, etc., can solve the problems of limited charge detection accuracy and large amount of calculation, and achieve the effect of reducing errors and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] An embodiment according to the invention for charge detection in an internal combustion engine is in Figures 1 to 4D shown in . The exemplary embodiment relates to determining a fresh air mass in a cylinder of an internal combustion engine.

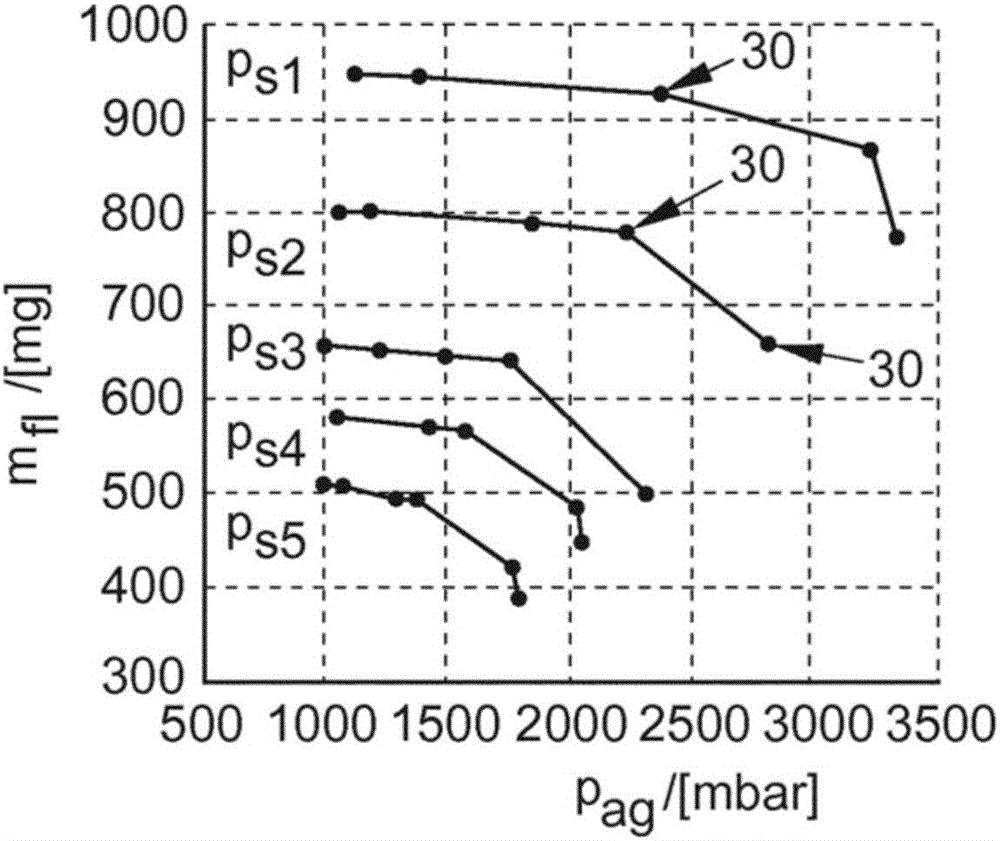

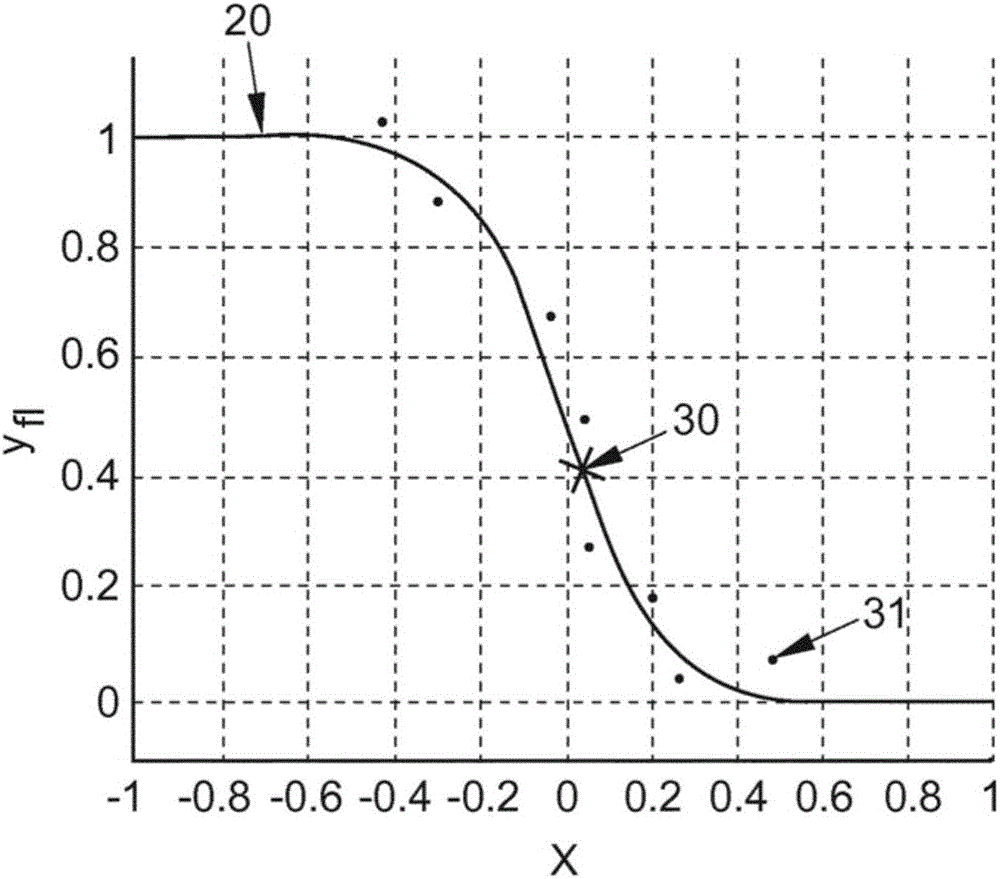

[0083] figure 1 A flow chart of the method according to the invention for carrying out the inflation detection 10 is shown. In a first step 100, fresh air mass measurements are provided as a function of the exhaust back pressure. exist figure 2 An example of measured data is shown in . figure 2 At constant speed n=1300 per minute and constant inlet valve position -20°KW and outlet valve position 5°KW for different intake manifold pressures p s1 =1400mbar,p s2 =1600mbar,p s3 =1800mbar,p s4 = 2200mbar and p s5 =2600mbar shows fresh air quality m fl The measured value of 30 is related to the exhaust back pressure p ag Relationship. Parts of the data set are displayed in each case for the measured values of the constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com