Sulfur-removing material, purification column using same, and pretreatment method for analysis of organic substances

A technology of purification column and inorganic filling material, which is applied in the pretreatment field of purification column and organic substance analysis, to achieve the effect of reducing cost, improving precision and high sulfur removal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

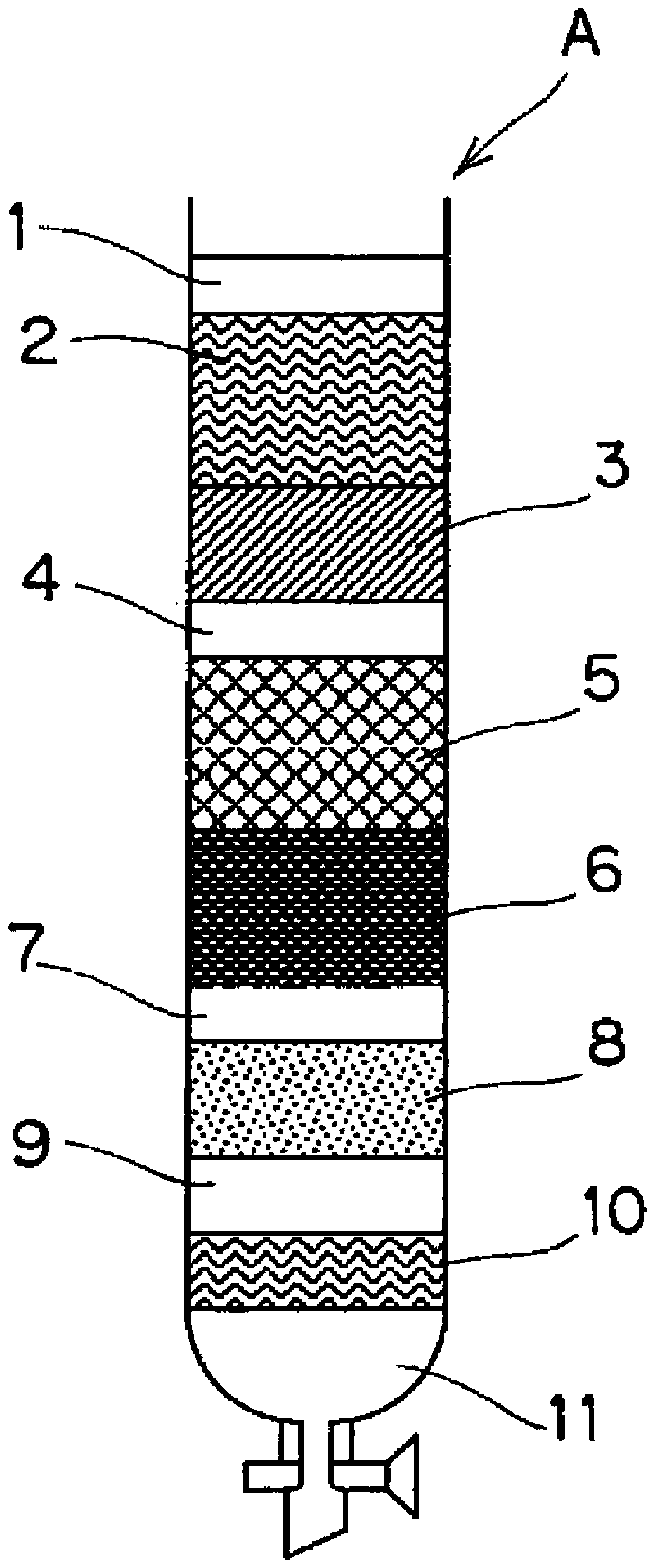

Method used

Image

Examples

Embodiment

[0052] Examples of the present invention are shown below, but the present invention is not limited to the following examples. In addition, unless otherwise specified, the following compounding ratio etc. are mass standards.

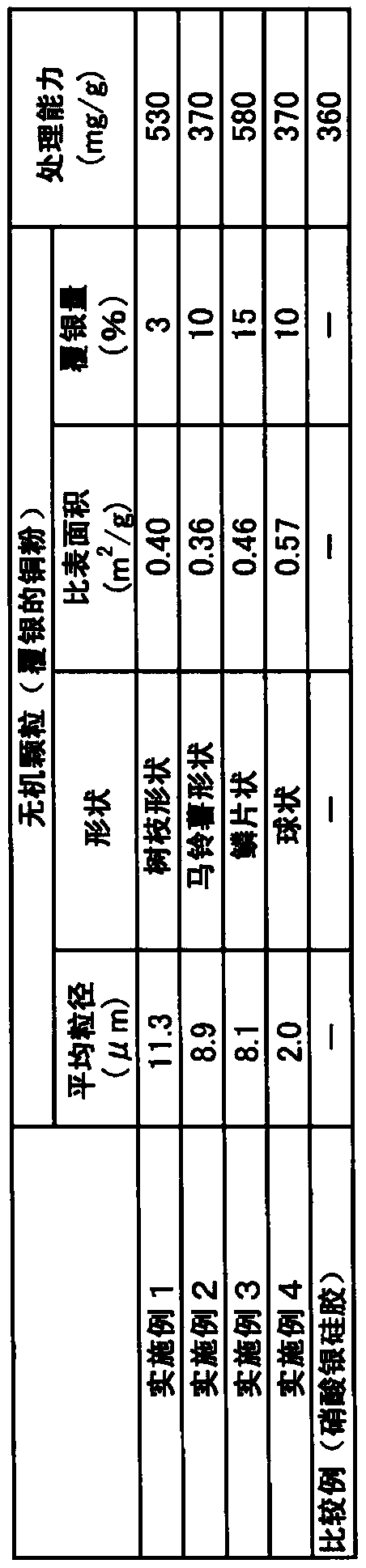

[0053] 1. Fabrication of Sulfur Removal Materials

[0054] As an example, 20 g of silica gel 60N (Cat. No. 37565-79) manufactured by Kanto Chemical Co., Ltd. and 1.4 g of various inorganic particles (silver-coated copper powder) shown in Table 1 were mixed with a mixer (TIETECH Co. , Ltd. manufactured AUTOMATICMIXER S-100) for vibration mixing. In addition, as a comparative example, silver nitrate silica gel (silver content: 6.5% by mass) was used.

[0055] In addition, the average particle diameter and specific surface area of the silver-coated copper powder were measured using the laser diffraction / scattering type particle size distribution measuring apparatus (manufactured by Nikkiso Co., Ltd., MT3300EXII).

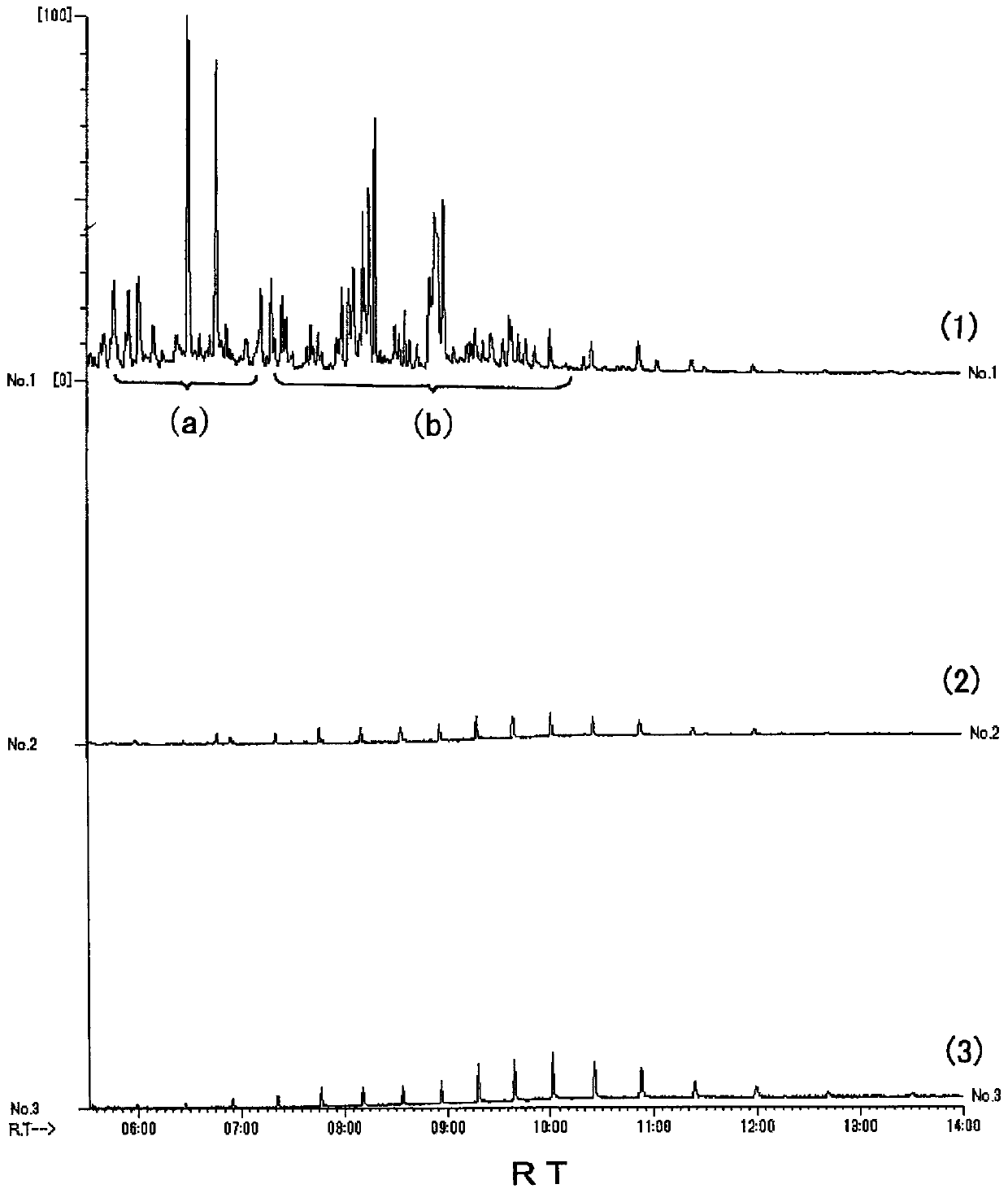

[0056] 2. Evaluation of Sulfur Removal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com