Fabrication of semi-polar crystal structures

A technology of crystal structure and anisotropy, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

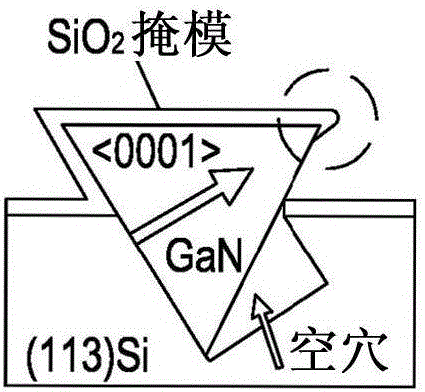

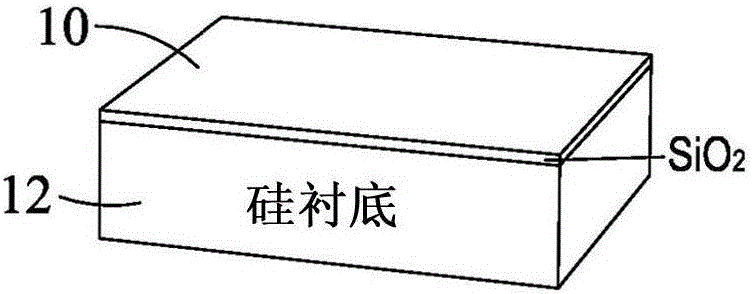

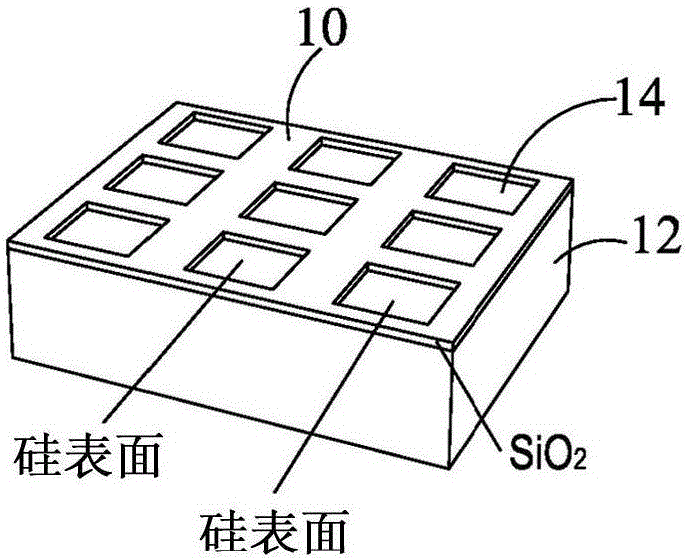

[0024] refer to Figure 2a to Figure 2e , a method for fabricating atomically flat (11-22) GaN templates on (113) silicon will now be described. First, a (113) silicon substrate, ie, a silicon substrate having a flat surface in the (113) plane of its crystal structure, is provided. like Figure 2a As shown, SiO was deposited on the surface of (113) silicon substrate 12 by plasma enhanced chemical vapor deposition (PECDV). 2 film10. In other embodiments, SiO can be deposited by electron beam evaporator or sputter deposition 2 . Then, if Figure 2b As shown, using standard photolithography and dry etching techniques (in this case, reactive ion etching RIE) 2 The film is etched through to an array of windows 14 (in this example, regular 2 x 2 μm sized square windows (although the window size could be larger) with about 1 μm spacing (although the spacing could be from 100 nm to 5 μm). Small or larger, square arrays from 500 x 500 nm to 10 x 10 μm) open across the wafer. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com