Engine oil anti-freezing separation device

A technology for separating device and oil, which is applied in the direction of refrigerators, refrigeration components, lighting and heating equipment, etc. It can solve the problems of compressor oil level drop, compressor burnt due to lack of oil, and high flow rate of mixed gas, so as to prolong the service life and save personnel The effect of reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

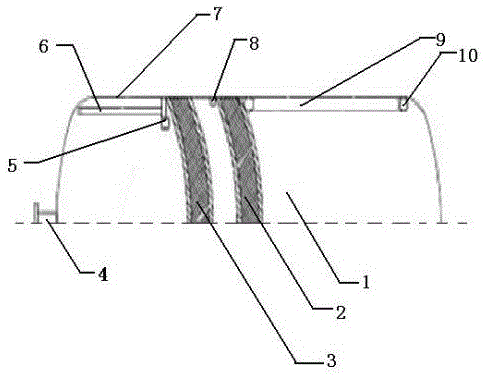

[0013] This embodiment provides an oil antifreeze separation device, characterized in that: the oil antifreeze separation device includes a cylinder (1), a sieve plate (2), a filter element (3), an oil discharge port (4), and an oil guide groove (5), oil pipe (6), cylinder wall (7), limit block (8), flow guide (9), oil inlet (10);

[0014] Among them: the oil inlet (10) is set at one end of the cylinder (1), the oil discharge port (4) is set at the other end of the cylinder (1), the separation device includes a flow guiding device and a filter device, and the oil inlet ( 10) Connect the deflector (9), the other end of the deflector (9) is channeled to the sieve plate (2), and the sieve plate (2) is provided with limit blocks (8) on both sides of the cylinder wall (7), and the sieve plate (2) ) and then install the filter element (3), the two sides of the filter element (3) are provided with an oil guide groove (5) against the cylinder wall (7), and the lower end of the oil gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com