Making method of dried mutton

A production method and technology of mutton jerky, which are applied in the direction of food ingredients as taste improvers, food ingredients as odor improvers, food ingredients containing natural extracts, etc., which can solve the problem of affecting the flavor of mutton, complex deodorization process of mutton, and mutton with and other problems, to achieve the effect of unique flavor, moderate salty taste and complete shape

Inactive Publication Date: 2017-03-08

习水县马临肉制品加工厂

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The present invention intends to provide a method for making mutton jerky to solve the problem that the current mutton deodorization process is relatively complicated, and the mutton after deodorization will have a slight smell of mutton, which affects the flavor of mutton

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

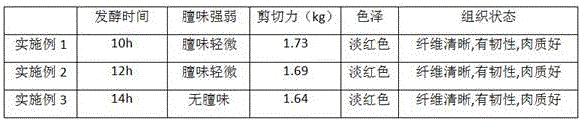

Embodiment 2

[0035] The difference between embodiment 2 and embodiment 1 is that the fermentation time is 12h;

Embodiment 3

[0037] The difference between embodiment 3 and embodiment 1 is that the fermentation time is 14h.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Shear force | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a making method of dried mutton. The making method comprises the following steps of step I, pretreating raw materials: selecting fresh sheep hindquarter, and performing cutting to obtain mutton blocks; step II, performing fermentation: putting the mutton blocks and lactic acid bacteria fermentation broth in a fermentation jar, and performing fermentation at 30 DEG C for 10-14h; step III, performing precooking: putting the fermented mutton blocks in water for cooking; step IV, performing cutting into slices: cutting the mutton blocks into mutton slices; step V, performing recooking: putting the mutton slices into water, adding seasoning, and performing cooking on the mutton slices and the seasoning; step VI, performing drying and baking: performing ventilation drying on the recooked mutton slices, and then performing baking; and step VII, performing packaging: after the mutton slices are baked, performing cooling and then performing vacuum packaging. The dried mutton made by the method can effectively remove mutton smelling of the mutton, and the making method is simple to operate. The made dried mutton is hygienic, tasteful, complete in shape of the mutton, and good in mouth feel.

Description

technical field [0001] The invention belongs to the field of food processing, and in particular relates to a method for preparing mutton jerky. Background technique [0002] Mutton is a traditional medicinal and nutritious special meat food. Because of its rich nutrition, it is a low-fat, low-cholesterol and high-protein nutritious food, rich in vitamins needed by the human body, so it is deeply favored and loved by consumers at home and abroad. Traditional Chinese medicine believes that mutton is warm in nature, nourishing qi and nourishing yin, warming the middle and nourishing the kidney, appetizing and invigorating the spleen, and benefiting fatigue. [0003] Beef jerky is common in the market, but mutton jerky is rare. This is because the smell of mutton is too strong. If there is no unique method when making mutton jerky, the resulting mutton jerky will easily contain mutton. Taste, resulting in poor taste, not accepted by consumers. Therefore, how to solve the prob...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A23L13/10A23L13/40A23L27/00A23L27/10

CPCA23V2002/00A23V2200/14A23V2200/15A23V2250/21A23V2250/1614

Inventor 肖仙佑

Owner 习水县马临肉制品加工厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com