Welding method for sheet chain structure

A welding method and chain technology, which are applied to the diagonal design and welding field of jewelry sheet chains, can solve problems such as hair pinching, easy deformation of pieces, and failure to increase product sales.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to further understand the features, technical means and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

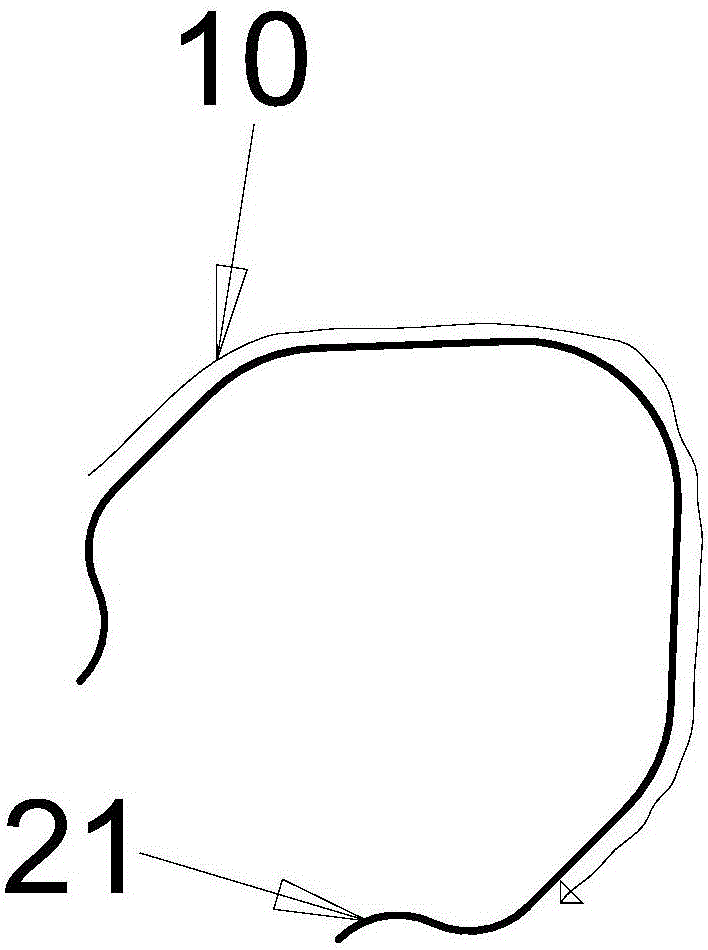

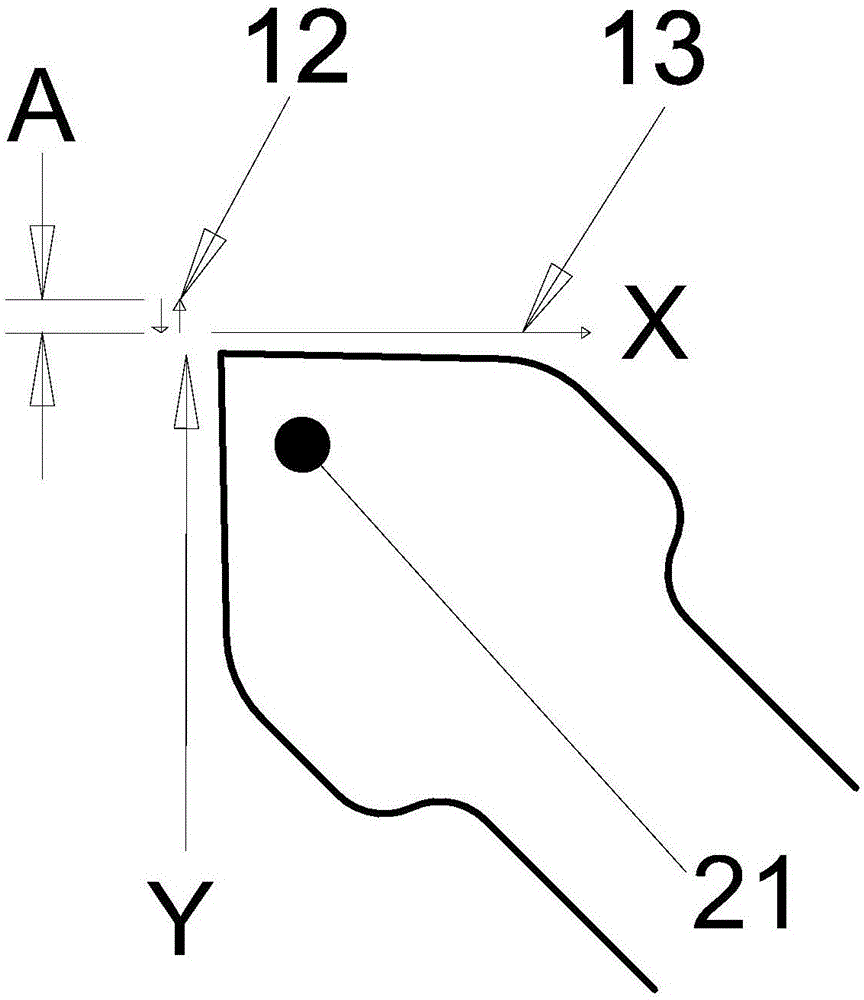

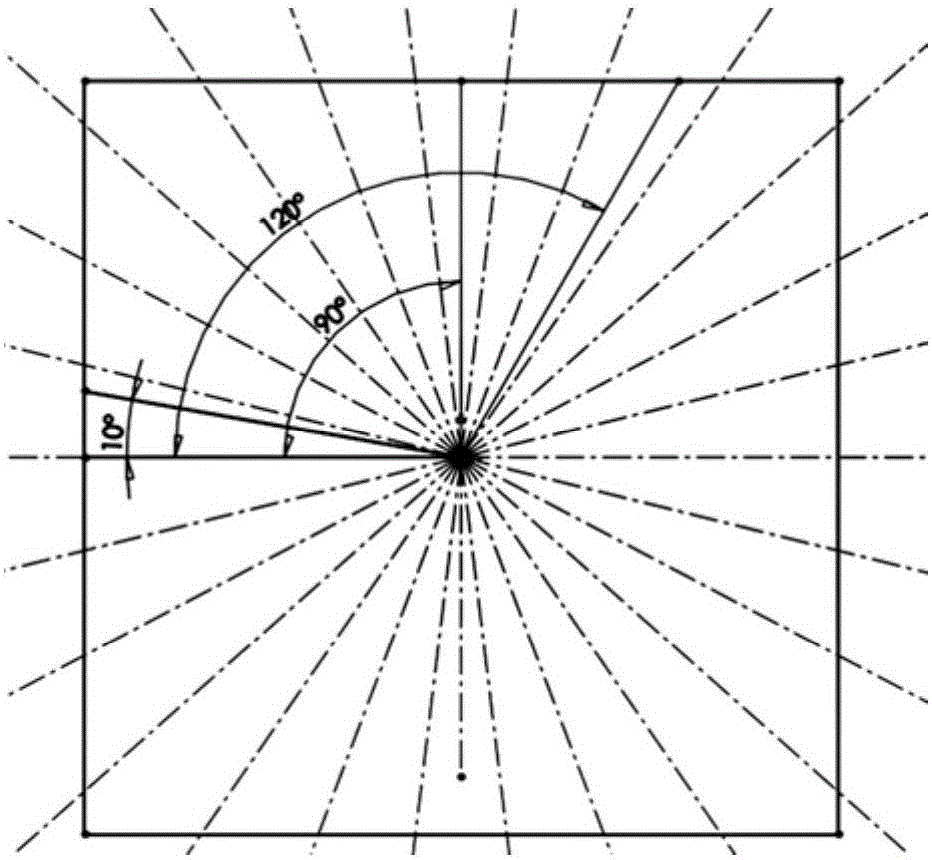

[0072] Please refer to the attached figure 1 as shown, figure 1 Schematic diagram of the new diagonal processing mode of the punch 21 punch; the punch 21 punch is tapered, and the punch 21 punch is processed along the Y direction first, and the processing distance A in the Y direction (the end position of the straight line processing is 12) is greater than 1 times Processing line diameter, punch 21 along the straight line processing terminal position 12 carriage returns of Y direction, then process punch 21 punches (processing exit route 13) along right-angled X direction. Y-direction wire cutting makes the wire cutting not process with corners, avoiding the circular edge surface formed by multiple R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com