High-performance liquid accelerator composition and preparation method thereof

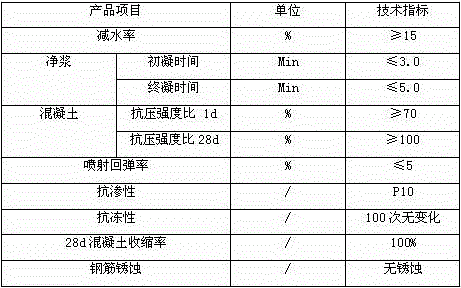

A composition and quick-setting agent technology, which is applied in the field of high-performance liquid quick-setting agent composition and its preparation, can solve the problems of large output, cement adaptability, poor workability of slurry, easy layering and precipitation, etc., and achieve rebound The effect of small rate, overcoming health damage, and no crystal precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take the preparation of 1000kg product as an example

[0035] To prepare a high-performance liquid quick-setting agent composition product, the proportion is based on weight, put 235kg of tap water and 450kg of aluminum sulfate into the mixing tank, and stir for 2 to 4 hours at 95 to 105°C until the solvent is fully dissolved; then Add 190kg of hydroxyl polyether, 55kg of propylene glycol, 40kg of anionic polyacrylamide, and 10kg of emulsified silicone oil, and stir for 1 to 1.5 hours. During the process, the temperature is maintained at 95 to 105°C; then add 20kg of sulfuric acid, and stir for 20 to 40 minutes to make it evenly mixed. Cool to normal temperature, shut down, obtain the high-performance liquid quick-setting agent product of the present invention.

Embodiment 2

[0037] Take the preparation of 1000kg product as an example

[0038] Prepare a high-performance liquid quick-setting agent composition product, and its proportioning is by weight, put 365kg of tap water, 310kg of aluminum sulfate, and 130kg of calcium sulfate into the mixing tank, and stir for 2 to 4 hours under the condition of 95 to 105°C until fully Solvent; then add 110kg hydroxy polyether, 60kg ethylene glycol, 10kg ultra-high molecular weight polyacrylamide, 5kg emulsified silicone oil in sequence, and stir for 1 to 1.5 hours. ~ 40min, make it mix evenly, cool to normal temperature, stop the machine, and obtain the high-performance liquid quick-setting agent product of the present invention.

Embodiment 3

[0040] Take the preparation of 1000kg product as an example

[0041] To prepare a high-performance liquid quick-setting agent composition product, the proportion is based on weight, put 130kg of tap water and 500kg of calcium nitrate into the mixing tank, and stir for 2 to 4 hours at 95 to 105°C until the solvent is fully dissolved; then Add 200kg of hydroxycarboxylic acid, 80kg of glycerol, 50kg of nonionic polyacrylamide, 10kg of polyoxypropylene glyceryl ether, stir for 1 to 1.5 hours, and maintain the temperature at 95 to 105°C during the process; then add 30kg of permanganate and stir for 20 ~ 40min, make it mix evenly, cool to normal temperature, shut down, and obtain the high-performance liquid quick-setting agent product of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com