Material for a concrete wave retaining wall

A wave wall and concrete technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of waste rubber occupying land resources, ordinary wave walls are not impermeable, and prone to cracks, etc. Achieve the effects of improving crack resistance and seepage resistance, improving volume stability, and enhancing frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

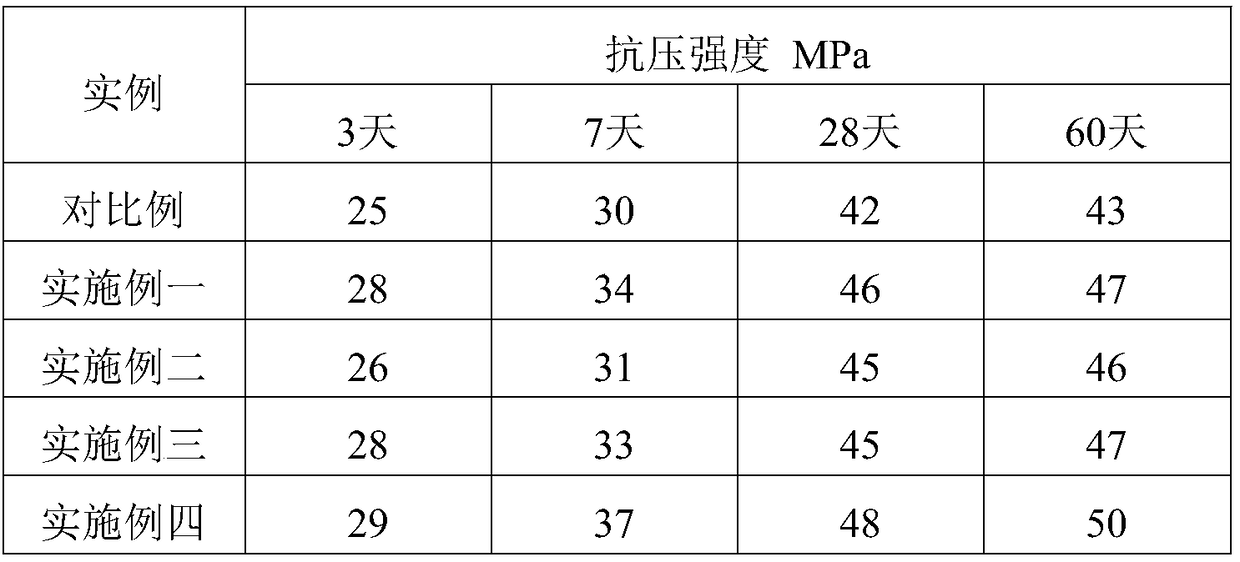

Examples

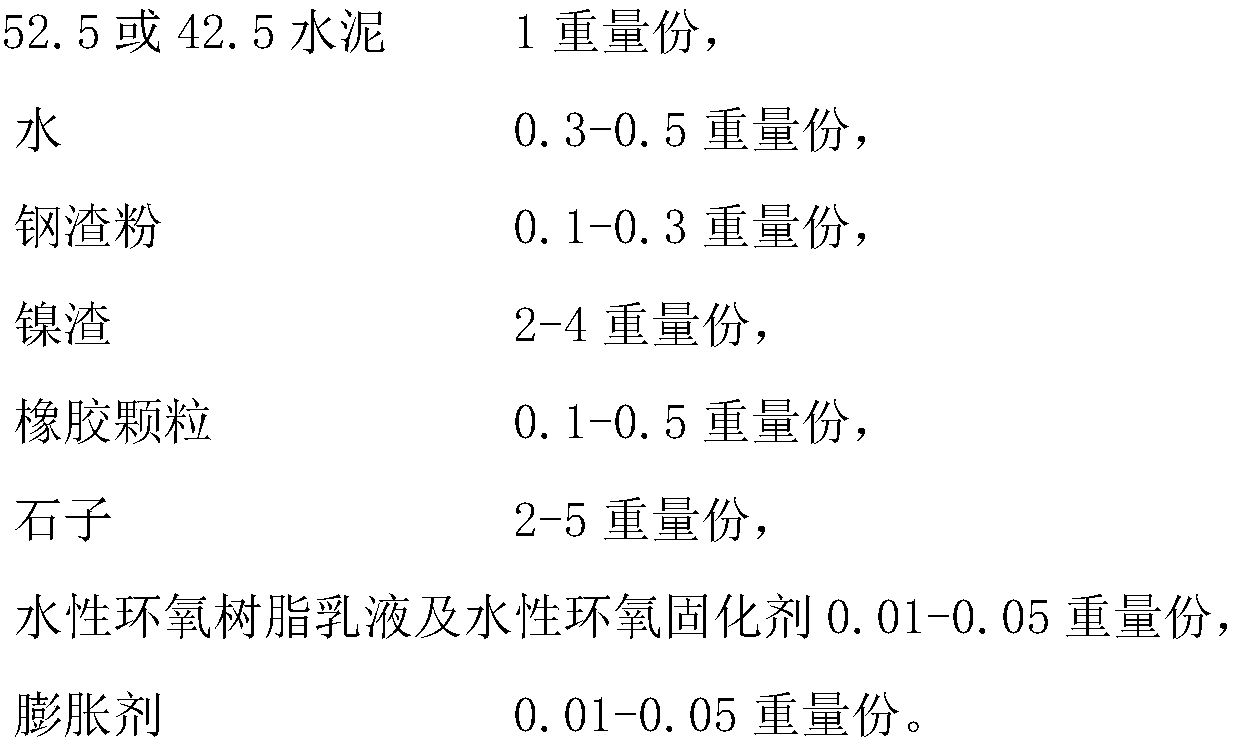

Embodiment 1

[0025] Concrete for the wave wall consists of the following parts by mass: 1 part by weight of PII 42.5 cement, 0.3 parts by weight of water, 0.2 parts by weight of steel slag powder, 4 parts by weight of nickel slag, 0.2 parts by weight of rubber particles, 5 parts by weight of stones, water-based epoxy resin emulsion 0.01 parts by weight, 0.01 parts by weight of water-based epoxy curing agent, and 0.01 parts by weight of expansion agent.

Embodiment 2

[0027] PII 42.5 parts by weight of cement, 0.35 parts by weight of water, 0.1 parts of steel slag powder, 2 parts by weight of nickel slag, 0.05 parts by weight of rubber particles, 3 parts by weight of stones, 0.05 parts by weight of water-based epoxy resin emulsion, 0.05 parts by weight of water-based epoxy curing agent parts, 0.02 parts by weight of expansion agent.

Embodiment 3

[0029] PII 52.5 parts by weight of cement, 0.5 parts by weight of water, 0.2 parts of steel slag powder, 2 parts by weight of nickel slag, 0.1 parts by weight of rubber particles, 2 parts by weight of stones, 0.04 parts by weight of water-based epoxy resin emulsion, 0.04 parts by weight of water-based epoxy curing agent parts, 0.05 parts by weight of expansion agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com