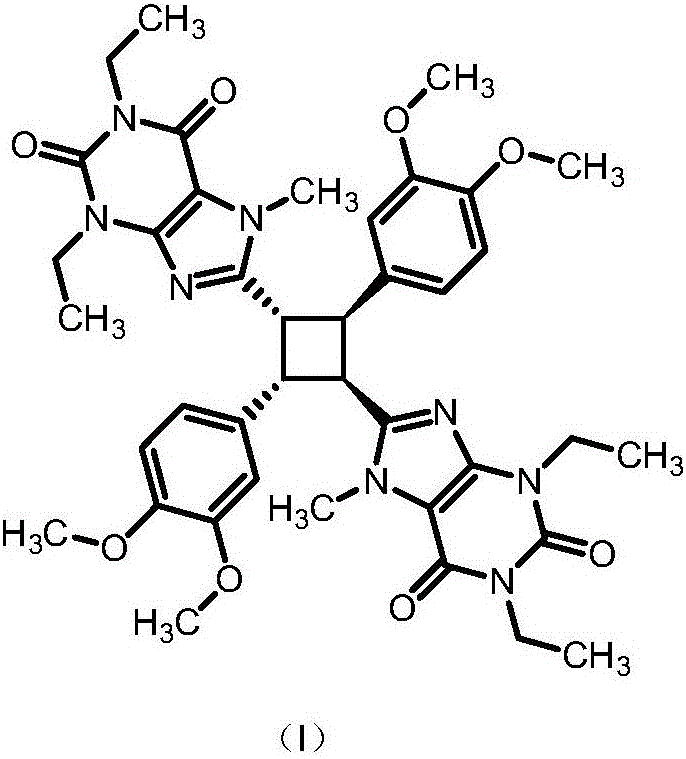

Preparation method of istradefylline impurity standard

A technology of istradefylline and a standard product, applied in the field of medicine, can solve the problems of cumbersome operation, large illumination area, low yield and the like, and achieve the effect that is easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation method of istradefylline impurity standard substance in the present embodiment is as follows:

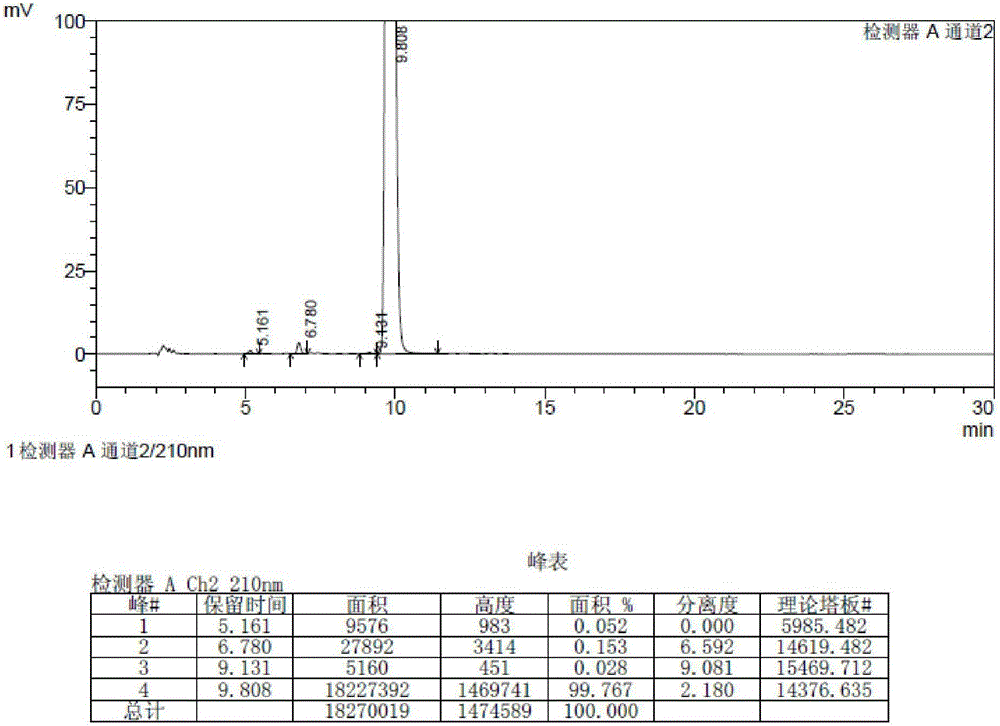

[0046] 1. Under the protection of nitrogen, put 200ml of chloroform, 3.5g (26mmol) of aluminum trichloride and 10g (26mmol) of istradefylline into a 500ml colorless glass reaction bottle in sequence, and stir at 30-40°C until completely dissolved , the reaction bottle was sealed, placed under a 254nm ultraviolet lamp for 10 hours, and the temperature was controlled at 35-40°C; after the reaction, the reaction solution was washed with 200ml of water and 200ml of saturated aqueous sodium chloride solution, and the organic layer was concentrated to dryness at 30-40°C under reduced pressure. , 9.4 g of impurity crude product was obtained, with a yield of 94.0%.

[0047]2. Add 100ml of dichloromethane to 9.4g of crude impurities, heat and stir at 30-35°C to dissolve, filter while hot, add 500ml of ethanol to the filtrate, stir and crystallize at 0-10°C for 1 hour, ...

Embodiment 2

[0058] The preparation method of istradefylline impurity standard substance in the present embodiment is as follows:

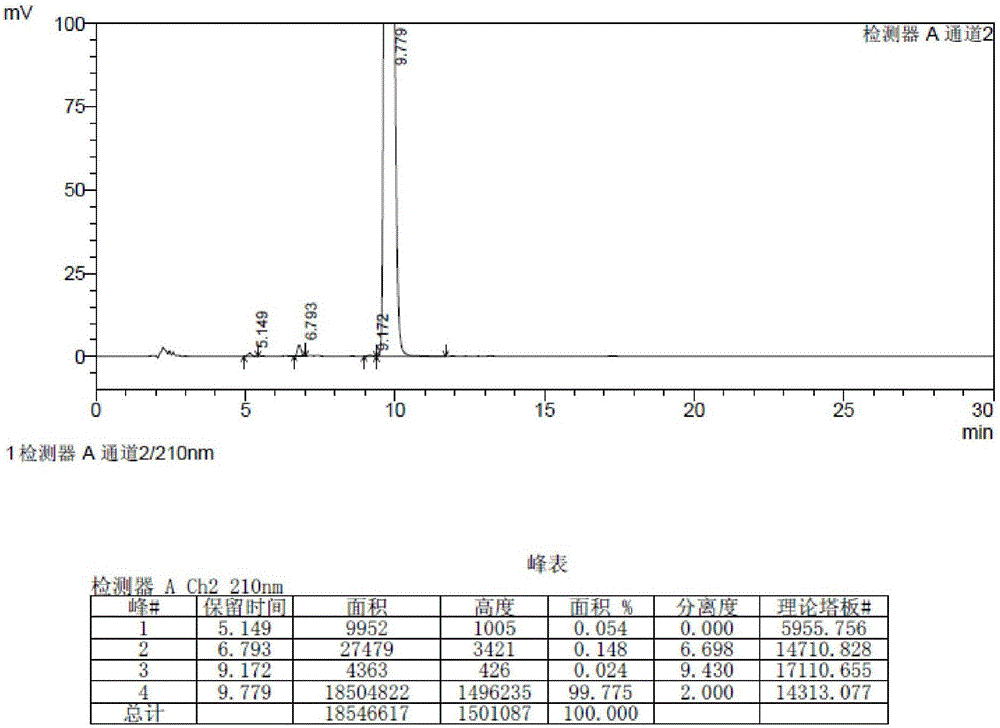

[0059] 1. Under the protection of nitrogen, put 500ml of chloroform, 14g (104mmol) of aluminum trichloride and 20g (52mmol) of istradefylline into a 1L colorless glass reaction bottle successively, stir at 30-40°C until completely dissolved, Seal the reaction bottle, put it under a 254nm ultraviolet lamp for 12 hours, and control the temperature at 35-40°C; after the reaction, the reaction solution was washed with 500ml of water and 500ml of saturated aqueous sodium chloride solution, and the organic layer was concentrated to dryness at 30-40°C under reduced pressure. 18.3 g of impurity crude product was obtained with a yield of 91.5%.

[0060] 2. Add 250ml of dichloromethane to 18.3g of crude impurities, heat and stir at 30-35°C to dissolve, filter while hot, add 2000ml of ethanol to the filtrate, stir and crystallize at 0-10°C for 2h, filter, and wash the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com