Heat conduction phase change composite material and preparation method thereof

A technology of composite materials and phase change materials, which is applied in the field of thermally conductive phase change composite materials and their preparation, can solve the problems of low thermal conductivity of thermally conductive silica gel, achieve the effects of enhancing thermal conductivity, increasing latent heat, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

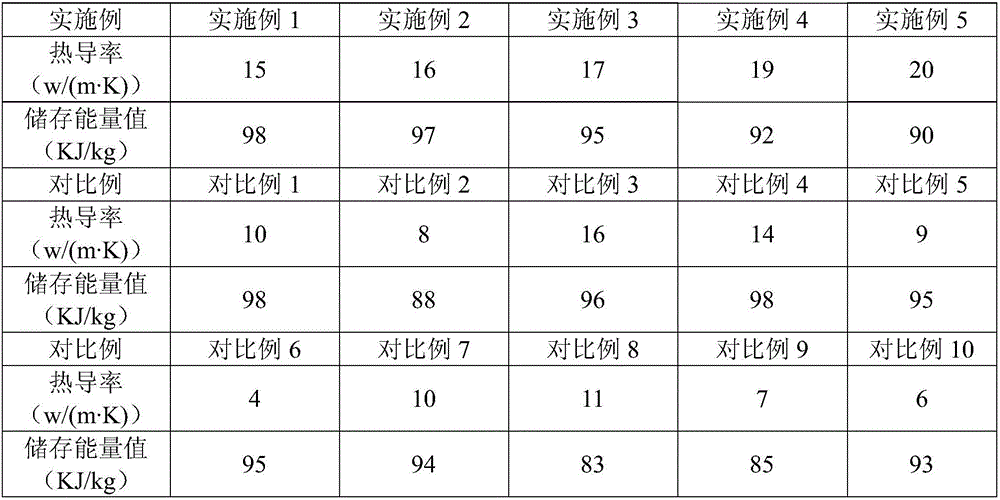

Examples

Embodiment 1

[0029] Prepare microcapsule phase-change materials with reference to the method of CN 105348797A, namely:

[0030] Add 4wt% graphene with a size of 0.9 μm to the molten n-tetradecane, pour it into a uniform 3wt% sodium dodecyl sulfate deionized aqueous solution under the condition of a 50°C water bath, and emulsify at a speed of 1500r / min 30min, while purging with nitrogen;

[0031] Add a polylactic acid-polyethylene glycol block polymer with a number average molecular weight of 8000 to the emulsified solution, stir for 30 minutes at a speed of 250 r / min, centrifuge and dry to obtain white particles, which are microparticles with a core-shell structure. Encapsulated phase change materials.

[0032] Graphene with a size of 0.9 μm and carbon nanotubes are mixed at a mass ratio of 1:3 to obtain thermally conductive fillers.

[0033] The thermally conductive filler and the microcapsule phase change material are mixed at a mass ratio of 1:9 to obtain a thermally conductive phase ...

Embodiment 2

[0036] Add 5wt% graphene with a size of 0.8 μm to the molten n-pentadecane, pour it into a uniform 3wt% sodium dodecyl sulfate deionized aqueous solution under the condition of a 50°C water bath, and emulsify at a speed of 1500r / min 40min, while purging with nitrogen;

[0037] Add a polylactic acid-polyethylene glycol block polymer with a number average molecular weight of 8500 to the emulsified solution above, stir for 30 minutes at a speed of 250 r / min, centrifuge and dry to obtain white particles, which are microparticles with a core-shell structure. Encapsulated phase change materials.

[0038] Graphene with a size of 0.8 μm and carbon nanotubes are mixed at a mass ratio of 1:2.5 to obtain thermally conductive fillers.

[0039] The thermally conductive filler and the microcapsule phase change material are mixed at a mass ratio of 1:8 to obtain a thermally conductive phase change material.

[0040] Mix the above-mentioned thermally conductive phase-change material with EV...

Embodiment 3

[0042] Add 6wt% graphene with a size of 1 μm to the molten n-hexadecane, pour it into a uniform 3wt% sodium dodecyl sulfate deionized aqueous solution under the condition of a water bath at 50°C, and emulsify at 1500r / min for 30 -40min, while purging with nitrogen;

[0043] Add a polylactic acid-polyethylene glycol block polymer with a number average molecular weight of 9000 to the emulsified solution above, stir for 30 minutes at a speed of 250 r / min, centrifuge and dry to obtain white particles, which are microparticles with a core-shell structure. Encapsulated phase change materials.

[0044] Graphene with a size of 1 μm and carbon nanotubes are mixed at a mass ratio of 1:2 to obtain thermally conductive fillers.

[0045] The thermally conductive filler and the microcapsule phase change material are mixed at a mass ratio of 1.2:8.4 to obtain a thermally conductive phase change material.

[0046] Mix the above-mentioned thermally conductive phase-change material with the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com