Zinc brushing machine for aluminum-zinc hot plating and application method thereof

A technology of hot-dip aluminum-zinc and zinc-coating machine, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of quality defects, too small installation space, scratches, etc., and achieve a compact and compact structure , Easy installation and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

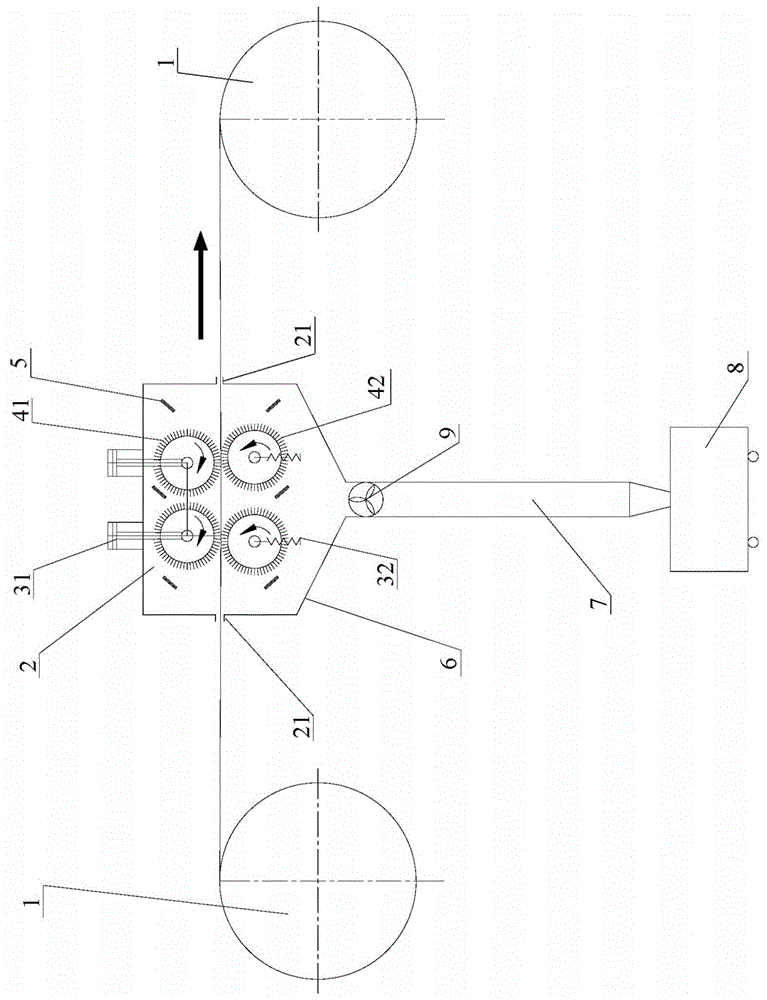

[0028] A zinc brushing machine for hot-dip galvanizing, comprising a pair of tower top rollers 1, a box body 2, a first elevator 31, a second elevator 32, an upper brush roller 41, a lower brush roller 42, an air nozzle 5, Collection funnel 6, zinc discharge pipe 7, collection vehicle 8 and exhaust fan 9, such as figure 1 As shown, the specific structure is:

[0029] The steel strip 11 is supported by the outer surfaces of a pair of tower top rollers 1 in turn;

[0030] The box body 2 is detachable. There is a strip steel groove 21 on the two opposite sides of the box body 2. The box body 2 is arranged between the two tower top rollers 1. The two strip steel grooves 21 are respectively facing one The tower top roller 1, the strip steel 11 penetrates into the box body 2 from one strip steel groove 21 of the box body 2, and then passes out of the box body 2 from another strip steel groove 21 of the box body 2;

[0031] The upper part in the box body 2 is provided with a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com