Upper portion and lower portion enlarged type cement soil composite pipe pile

A technology of cement-soil piles and cement-soil mixing piles, which is applied in the field of foundation engineering, can solve the problems of pile diameter, pile length increase, waste, etc., and achieve the effect of saving concrete and steel bars, good effect, and saving cast-in-place pile materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

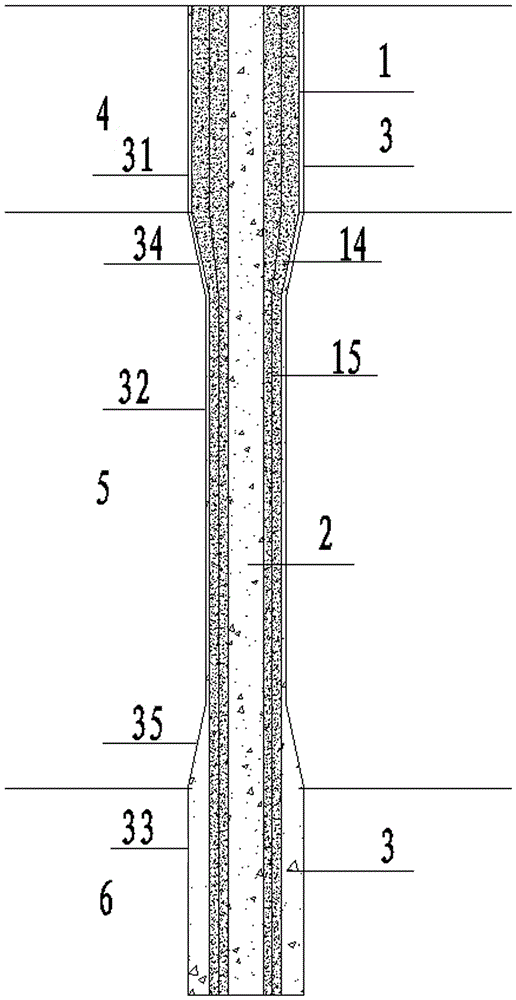

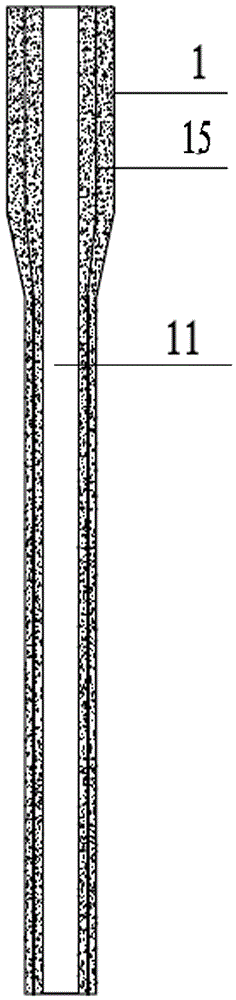

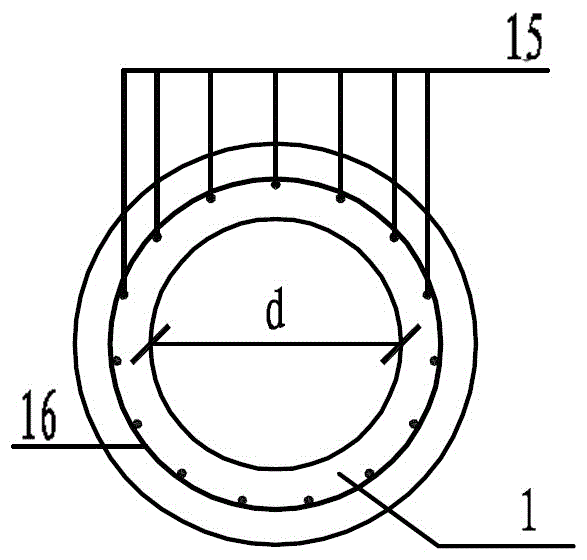

[0037] Such as figure 1 , figure 2 with image 3 The described upper and lower enlarged cement-soil composite pipe piles include prefabricated concrete pipe piles 1, a central hole 11 is arranged in the prefabricated concrete pipe piles, and the first cement-soil piles 2 are filled in the central hole 11, and the prefabricated concrete pipe piles A second cement-soil pile 3 is arranged outside the pile 1, and the first cement-soil pile 2 and the second cement-soil pile 3 are cast-in-situ cement piles. The prefabricated concrete pipe pile 1, the first cement-soil pile 2 and the second cement-soil pile 3 are arranged coaxially. The pile diameter of the second cement-soil pile 3 is at least 20 mm larger than the outer diameter of the precast concrete pipe pile 1 . The second soil-cement pile 3 includes upper, middle and lower sections, the upper section 31 of the soil-cement pile is located at the cohesive soil 4 (relatively hard soil layer) in the hard plastic-hard state, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com