Electric hydraulic excavator

A technology for hydraulic excavators and electric motors, applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc. Problems such as large motor size and high motor cost can achieve the effect of increasing energy recovery and auxiliary functions, convenient power supply, and improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

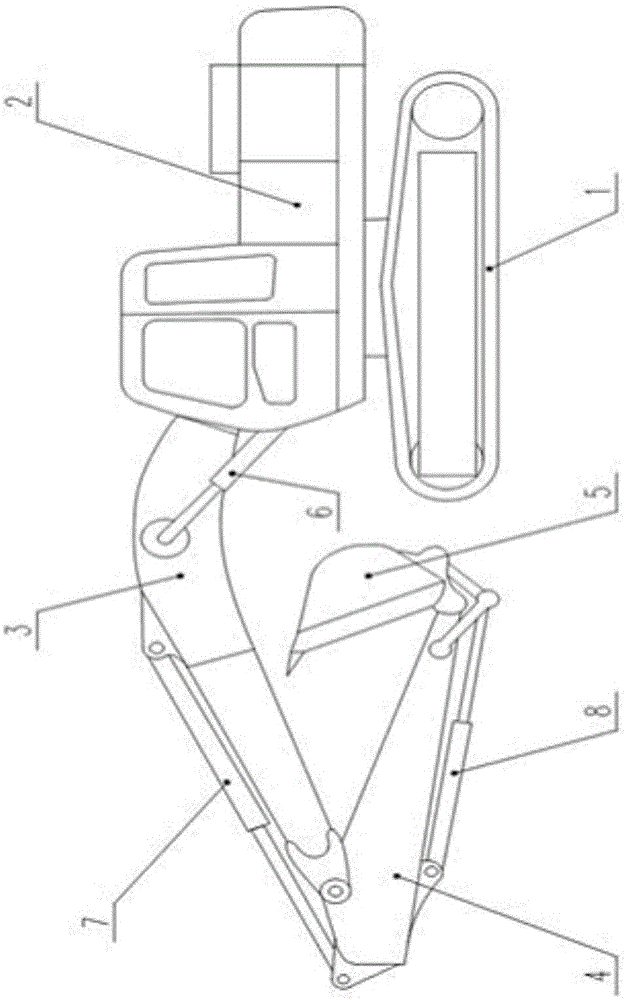

[0038] Example 1: figure 1 As shown, an electro-hydraulic excavator, the mechanical system includes a traveling body 1, a rotating body 2 arranged on the traveling body 1, a boom 3 connected with the rotating body to rotate up and down, and an arm mounted on the front end of the boom 4. A bucket 5 installed at the front end of the stick 4, a pair of boom hydraulic cylinders 6 for driving the boom 3, a stick hydraulic cylinder 7 for driving the stick 4, and a bucket hydraulic cylinder 8 for driving the bucket. The driver's control room is set on the rotating body 2, and the rotating body 2 is installed on the running body 1. The driver operates the driving body 1, rotating body 2, boom 3, stick 4, and bucket 5 respectively or in combination. Excavation of soil and sand, bulldozing, or rolling operations to tighten the ground.

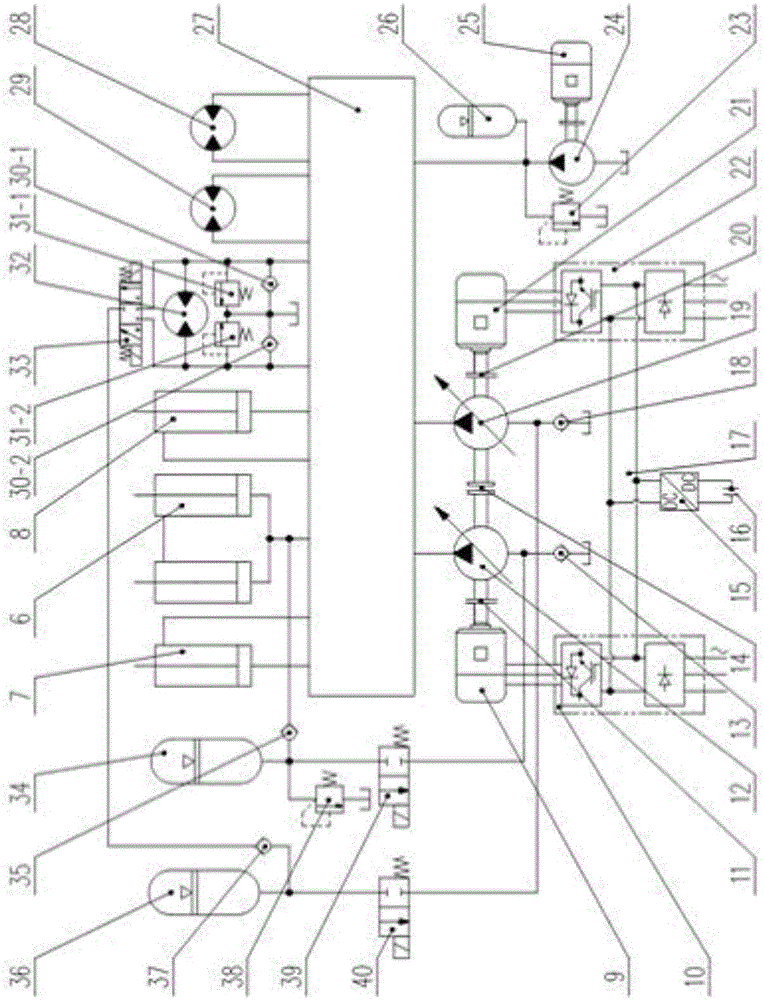

[0039] figure 2 As shown, the control system, the boom hydraulic cylinder 6, the stick hydraulic cylinder 7, the bucket hydraulic cylinder 8, the swi...

Embodiment 2

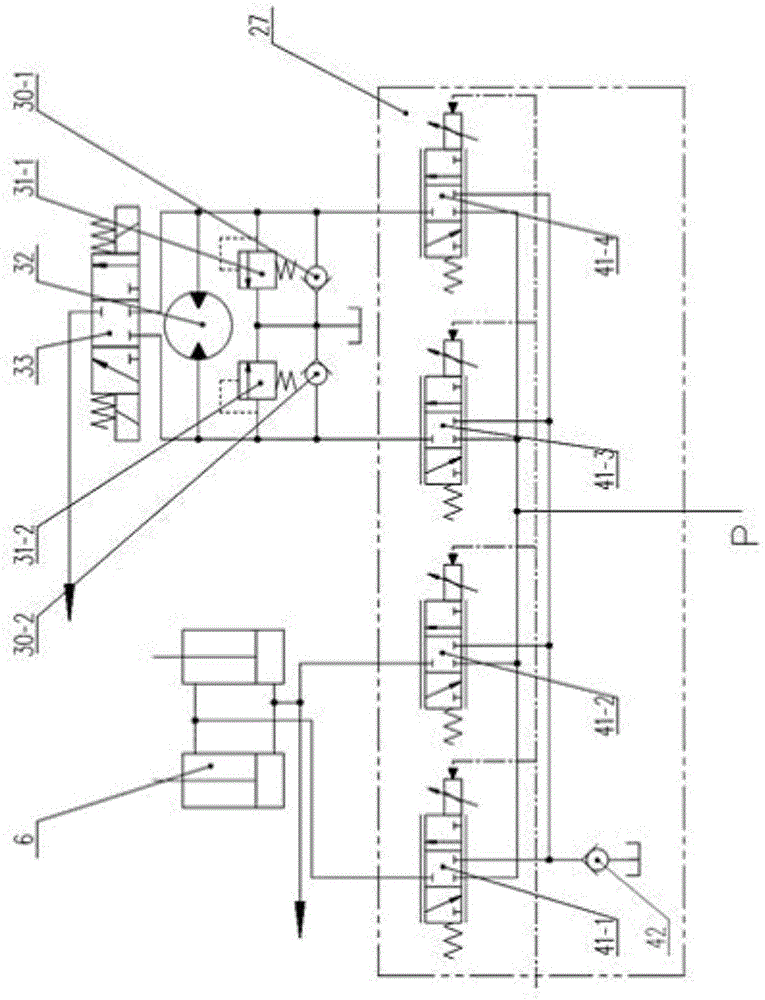

[0051] Embodiment 2: as Figure 4 As shown, the difference between this embodiment and Embodiment 1 lies in the accumulator auxiliary circuit: the first hydraulic pump 12 and the second hydraulic pump 19 are simultaneously assisted by the low-pressure accumulator 34 or the high-pressure accumulator 36 . The oil outlets of the high-pressure accumulator 36 and the low-pressure accumulator 34 are connected to two oil inlets of the second three-position three-way electromagnetic reversing valve 43, and the oil outlets of the second three-position three-way electromagnetic reversing valve 43 are connected to the The oil suction port of the first hydraulic pump 12, the oil outlet port of the first one-way valve 13, the oil suction port of the second hydraulic pump 19, and the oil outlet port of the second one-way valve 18 are connected. By controlling the second three-position three-way electromagnetic reversing valve The transposition of 43 determines whether the high-pressure accu...

Embodiment 3

[0052] Example 3: Figure 5 As shown, the difference between this embodiment and Embodiment 2 is that the second hydraulic pump 19 is a double displacement pump, and the second motor 21 is a servo motor. The second electric motor 21 is connected with the second hydraulic pump 19 through the second coupling 20 , and the displacement of the second hydraulic pump 19 is adjusted by controlling the rotation speed of the second electric motor 21 through the second frequency converter 22 . Due to the fast dynamic response of the servo motor, the low-pressure accumulator 34 and the high-pressure accumulator 36 can only assist the first hydraulic pump 12 . The oil outlet of the second three-position three-way electromagnetic reversing valve 43 is connected with the oil suction port of the first hydraulic pump 12 and the first one-way valve 13 oil outlets, by controlling the second three-position three-way electromagnetic reversing valve 43 The shifting determines whether the high pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com