Single-scroll fireproof shutter

A technology of fire shutters and reels, applied in fire doors, door/window protection devices, shading screens, etc., can solve the problems of large building space, low industrial energy efficiency, and heavy weight, and achieve compact overall structure, long service life, The effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

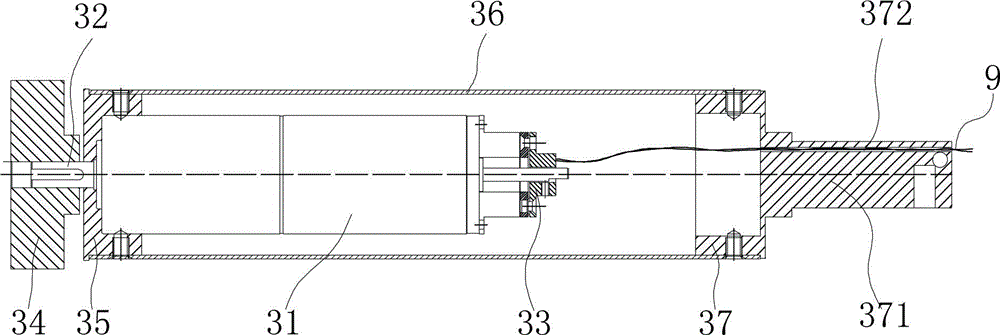

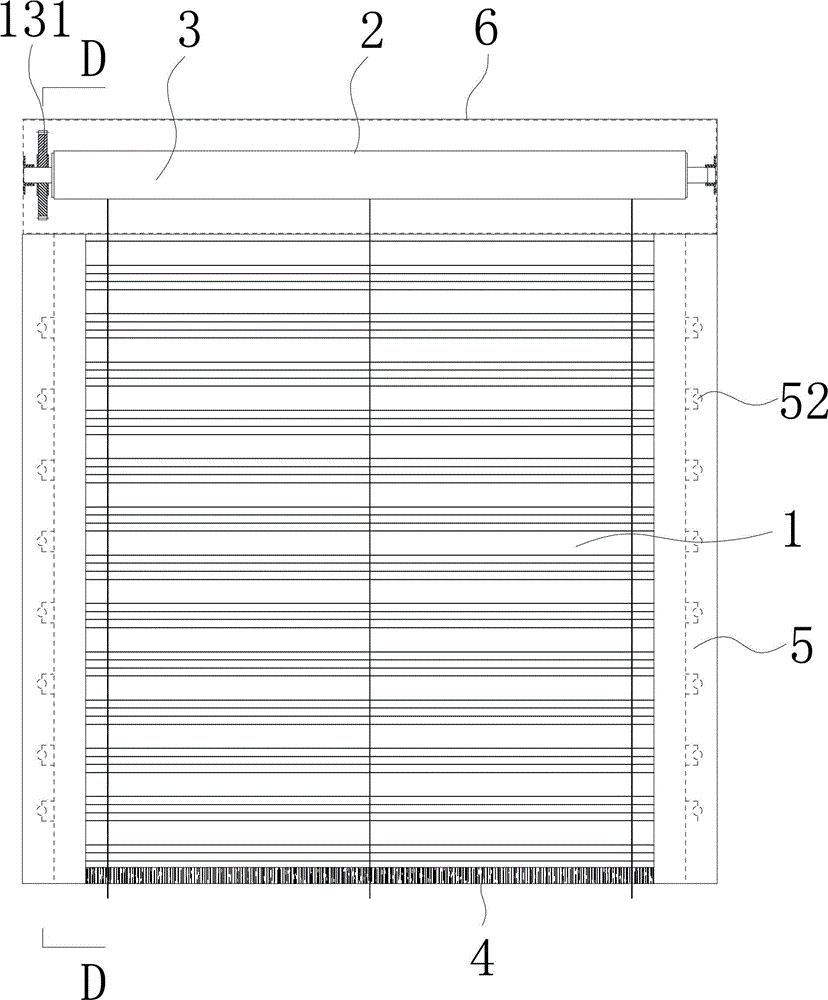

[0029] Example 1, see attached Figure 1~2 , 4~6.

[0030] A single-scroll fire-resistant roller shutter. The fire-resistant roller curtain surface 1 is a flexible single-layer fire-resistant fabric structure with a thickness of ≤3 mm; the curtain surface 1 is a winding structure; the upper end of the fire-resistant roller curtain surface 1 is connected to a roller 2, and the lower end A bottom rod 4 is connected; a rolling door machine 3 is also provided. The rolling door machine has a built-in motor 31. One end of the rolling door machine is provided with a transmission wheel 34 through the motor output shaft 32, and the other end of the motor 31 is provided with an energized coupling brake 33; 36 is fixedly connected to the housing of the motor 31; the weight of the bottom rod 4 is greater than the damping of the motor.

[0031] The outer sleeve 36 can be fixedly connected to the housing of the motor 31 through a support 35; the other end of the outer sleeve is fixedly connected...

Embodiment 2

[0039] Example 2, see attached Figure 7~8 .

[0040] The curtain surface 1 adopts a folding structure; the folding structure is perforated on both sides of the curtain surface, and a metal rope 7 is passed through the holes on both sides. The upper end of the metal rope is fixed on the reel and the lower end is fixed on the bottom rod 4. When in use, the reel drives the metal rope to retract the curtain surface, and the curtain surface is folded into a folding structure. The rolling door machine is located in the inner cavity of the reel 2 and has a built-in structure.

[0041] Other structures are the same as in Example 1.

Embodiment 3

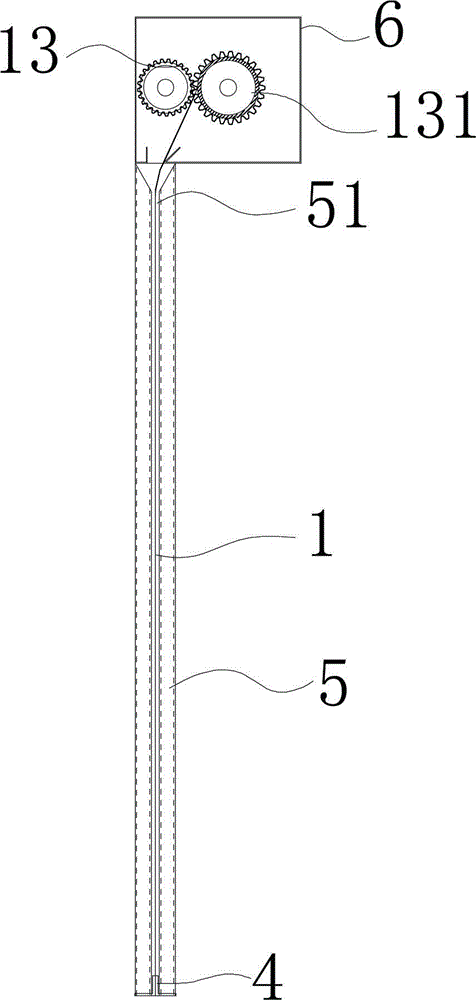

[0042] Example 3, see attached Figure 9-10 .

[0043] The curtain surface 1 is a winding structure.

[0044] The rolling door machine 3 is an external type; the other end of the rolling door machine 3 is provided with a fixed shaft 371; the rolling door machine 3 is an external type; the rolling door machine 3 is located outside the reel 2; 3 The transmission wheel 34 at the other end is a sprocket 12 or a gear 13; both ends of the reel 2 are provided with a fixed shaft 11, and one end of the fixed shaft is provided with a sprocket 121 or a gear 131; and the sprocket 12 on the rolling door Or gear 13 meshing transmission connection;

[0045] The bearing 8 is provided, and during installation, both the rolling door machine and the reel are fixed on a fixed object.

[0046] The fixed object may be the box body 6. During installation, both ends of the reel are provided with bearings 8. The reel is fixedly connected in the box body 6 through the fixed shaft 11, the bracket 10, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com