Potato pulp preparation method and potato pulp prepared by same

A potato, mass concentration technology, applied in the function of food ingredients, food science, application and other directions, can solve the problems of reducing the efficiency of potato processing technology, high residual potato skin, and insufficient peeling. Guarantee quality and avoid the effect of food poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

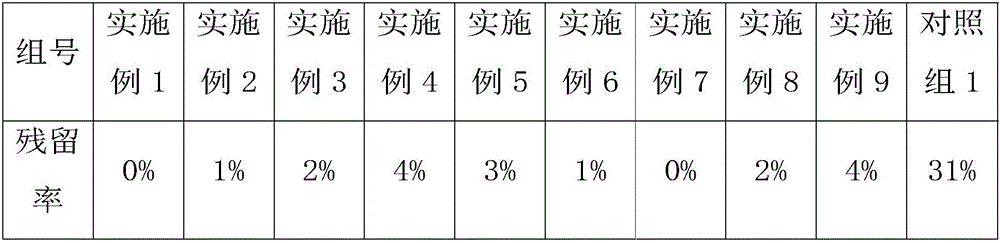

[0042] Use a cleaning machine to clean 100 freshly selected potatoes for the first time. After the first cleaning for 10 minutes, perform the second cleaning, and then put the cleaned potatoes into the cleaning cavity of the large ultrasonic cleaning machine and clean them Pour a solution containing KOH with a mass fraction of 6% and ethanol with a volume percentage of 90% into the chamber. Under the conditions of a solution temperature of 75°C and an ultrasonic frequency of 20KHz, the skin is removed by stirring at 60r / min for 6min to obtain the epidermal residual rate For 0% peeled potatoes, the remaining skin ratio refers to the number of potatoes with skin remaining on the potato compared to the total number of potatoes.

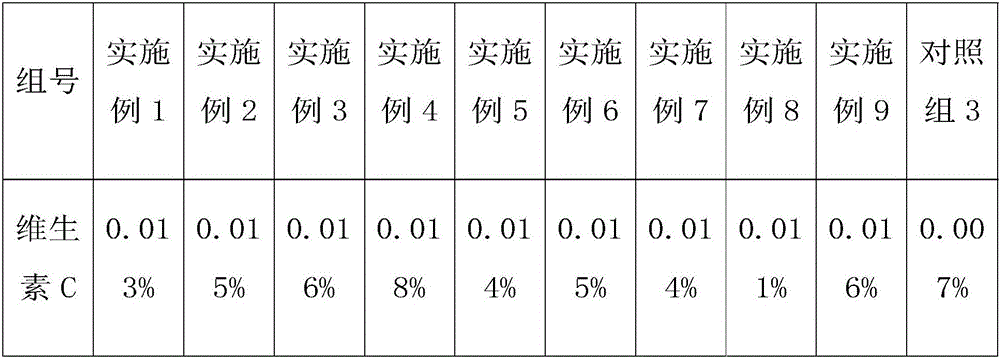

[0043] After the peeling is completed, remove the potato peels, and discharge the peeling solution in the cleaning cavity, and then pour into the cleaning cavity containing 7% citric acid, 3% ascorbic acid and 0.5% glutathione. The aqueous solution of th...

Embodiment 2

[0046] Use a cleaning machine to clean 100 freshly selected potatoes for the first time. After the first cleaning for 10 minutes, perform the second cleaning, and then put the cleaned potatoes into the cleaning cavity of the large ultrasonic cleaning machine and clean them Pour a solution containing KOH with a mass fraction of 8% and ethanol with a volume percentage of 70% into the cavity. Under the conditions of a solution temperature of 65°C and an ultrasonic frequency of 40KHz, the skin is removed by stirring at 70r / min for 7min to obtain the epidermal residual rate For 1% of peeled potatoes, the remaining skin ratio refers to the number of potatoes with skin remaining on the potato compared to the total number of potatoes.

[0047] After the peeling is completed, remove the potato skins, and drain the peeling solution in the cleaning cavity, and then pour the solution containing 3% citric acid, 7% ascorbic acid and 1% glutathione into the cleaning cavity. The aqueous solut...

Embodiment 3

[0051] Use a cleaning machine to clean 100 freshly selected potatoes for the first time. After the first cleaning for 10 minutes, perform the second cleaning, and then put the cleaned potatoes into the cleaning cavity of the large ultrasonic cleaning machine and clean them Pour a solution containing 7% KOH by mass fraction and 80% ethanol by volume into the cavity, and remove the skin under stirring at 65r / min for 10min at a solution temperature of 70°C and an ultrasonic frequency of 30KHz to obtain the epidermal residual rate For 2% peeled potatoes, the skin residual ratio refers to the number of potatoes with skin remaining on the potato compared to the total number of potatoes.

[0052] After the peeling is completed, remove the potato peels, and discharge the peeling solution in the cleaning cavity, and then pour into the cleaning cavity containing 5% citric acid, 5% ascorbic acid and 0.7% glutathione. The aqueous solution of the polyphenol oxidase inhibitor is soaked for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com