Implant system with straight base station

A technology of implants and straight abutments, applied in the field of implant systems, can solve problems such as implant failure, high cutting resistance, and stress concentration, and achieve the effects of reducing the chance of infection, small cutting resistance, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

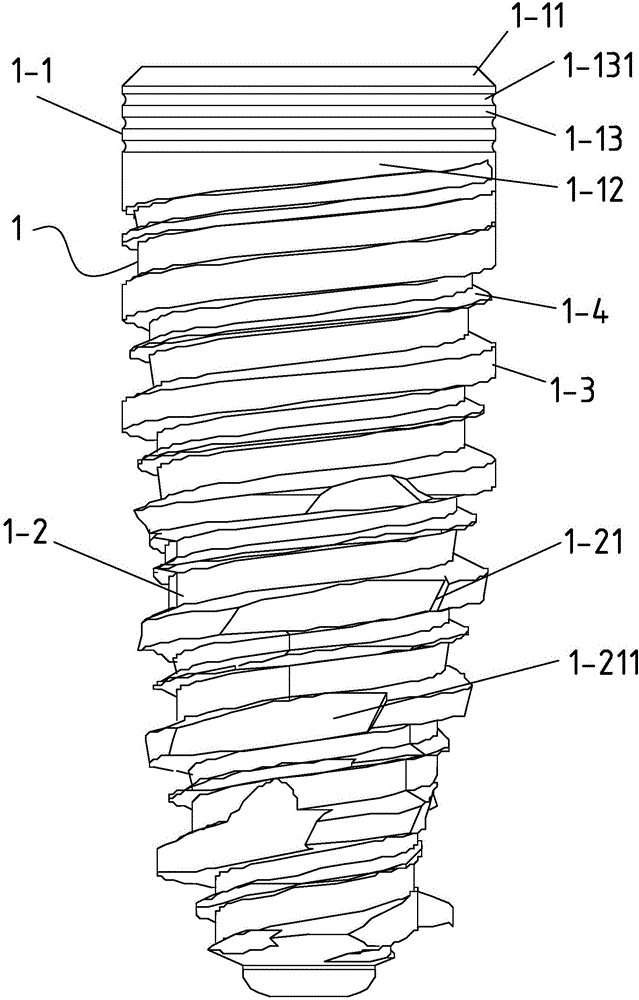

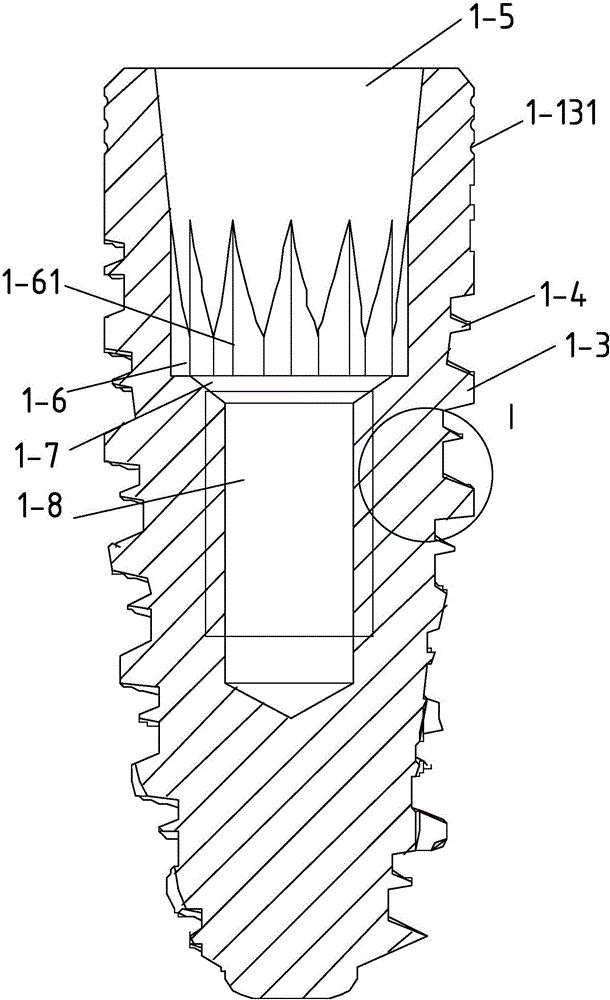

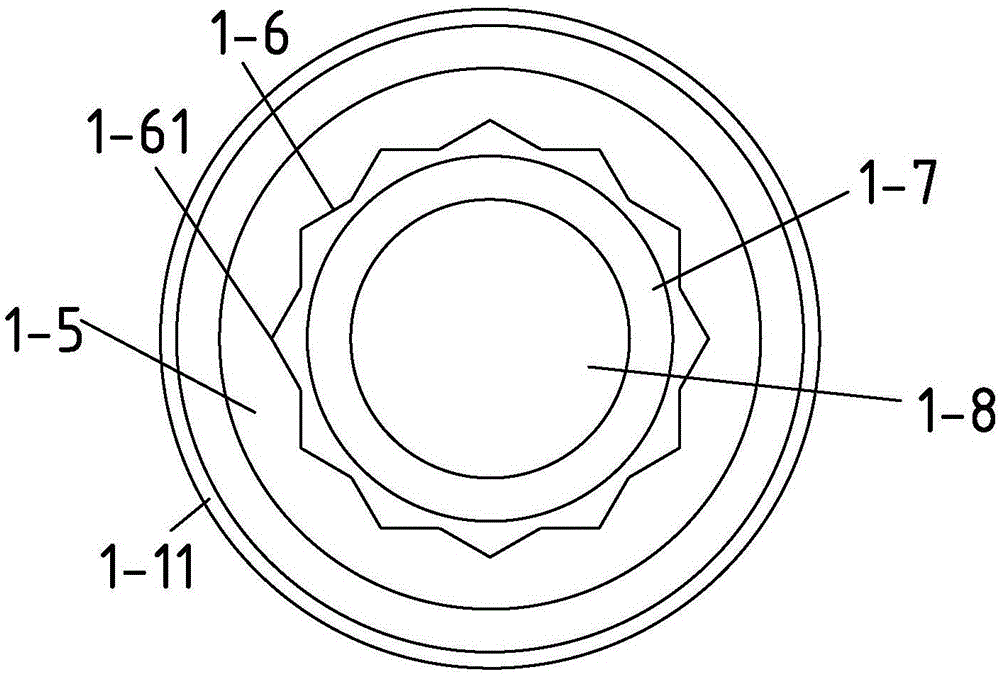

[0041] like Figure 1-Figure 8 As shown, an implant system with a straight abutment is characterized in that it includes an implant 1, a straight abutment 2 and a central bolt 3, and the implant 1 includes a neck 1-1 and a head connected in sequence 1-2, the neck 1-1 is cylindrical, including a chamfered round table 1-11 at the top of the neck 1-1, a threaded section 1-12 connected to the head 1-2 and a The groove section 1-13 between the chamfered round table 1-11 and the threaded section 1-12, the head 1-2 is in the shape of a truncated cone, and its large end is connected to the threaded section 1-12 , the outer surface of the head 1-2 has a thread extending to the thread segment 1-12, the thread includes a main thread 1-3 and a secondary thread 1-3 between the helical intervals of the main thread 1-3 4. The outer diameter of the neck 1-1 is 2-6 mm, the height of the chamfered round table 1-11 is 0.1-0.3 mm, and the height of the implant 1 is 5-15 mm.

[0042] The lead a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com