3D printer spray head with nozzle diameters changed in real time

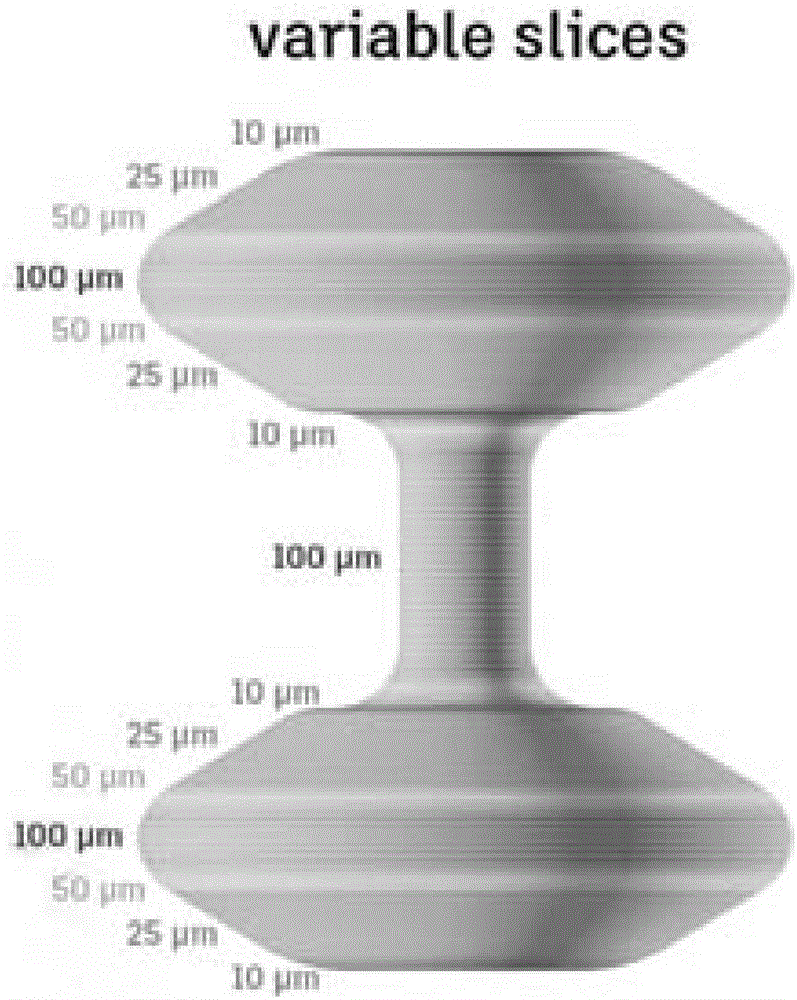

A 3D printer, nozzle diameter technology, applied in 3D object support structures, coating devices, additive manufacturing, etc., can solve problems such as inability to apply 3D printers, inability to realize real-time automatic real-time nozzle switching, etc., to save processing time, guarantee The effect of machining accuracy and improving printing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is specifically described below by the embodiment, only for further illustrating the present invention, can not be interpreted as the limitation of protection scope of the present invention, the technical engineer of this field can make some non-essential improvements and improvements to the present invention according to the content of the above-mentioned invention Adjustment.

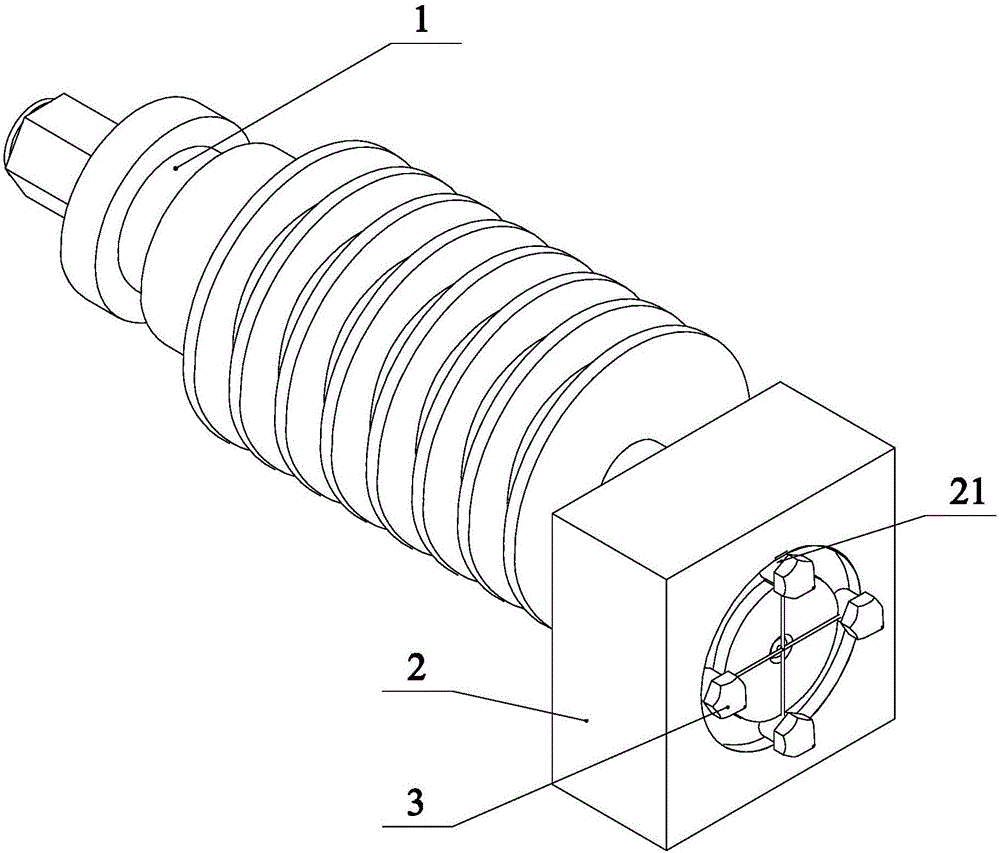

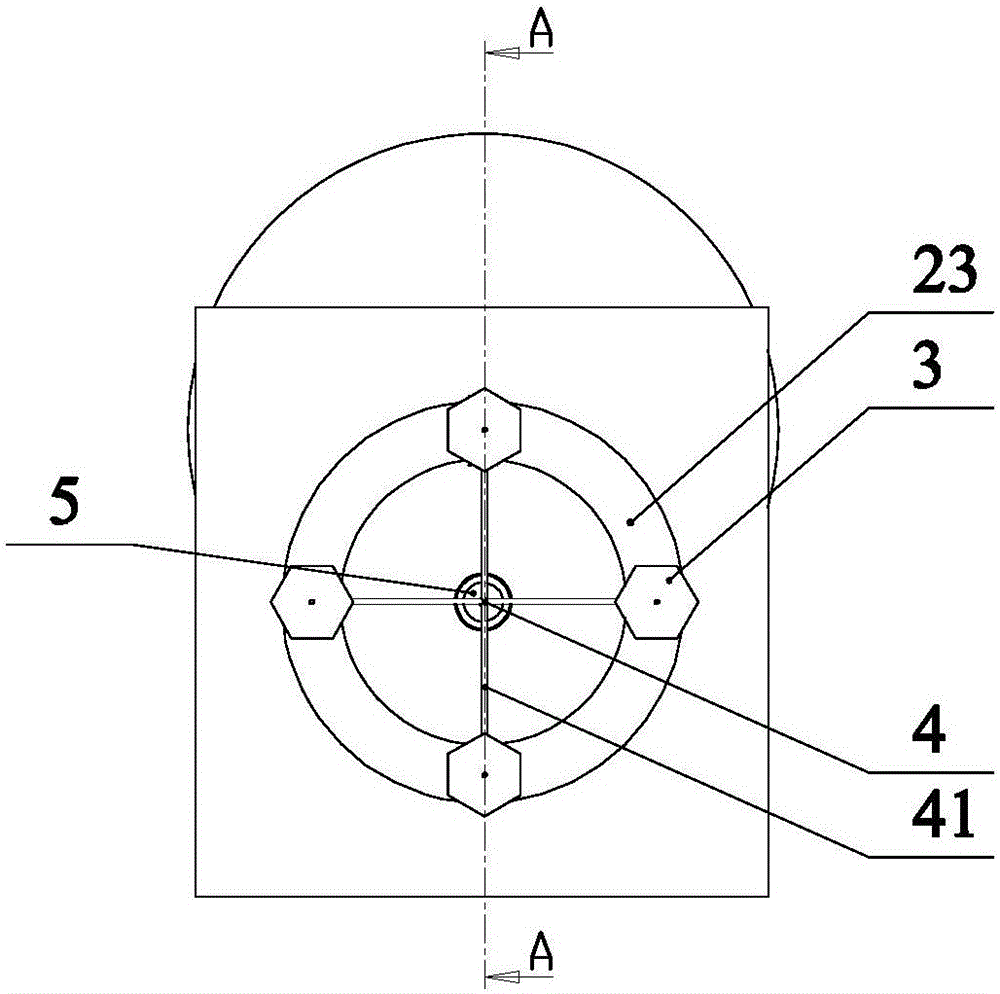

[0022] Such as Figure 1-4 The specific embodiment of the present invention shown includes a feed throat 1 and a heating block 2 arranged at the outer end of the feed throat. The heating block is generally an aluminum alloy heating block, and a heating resistance element is arranged therein. As a conventional accessory in this field, the lower end surface of the heating block 2 is provided with a nozzle docking position 21, and the nozzle docking position 21 is provided with a heating block outlet 22 whose inner end communicates with the feeding inner tube 11 of the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com