A kind of preparation method of fiber-reinforced PBT composite material fusion connection joint

A composite material and fiber reinforced technology, applied in the field of thermoplastic materials, can solve the problems of poor interface compatibility in the connecting area of PBT composite materials, and achieve the effect of improving poor interface compatibility, light weight, and easy mold clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The fiber cloth material in this embodiment is the woven basalt fiber cloth with a single layer thickness of 0.4 mm produced by Sichuan Tuoxin Research Institute; the catalyst used is the dihydroxybutyl chloride produced by Guangzhou Yuansu Chemical Co., Ltd. Tin; the CBT resin used is a model of CBT100 produced by Cyclics in the United States, and it was dried in a vacuum oven at 105°C for 10 hours before use.

[0031] The preparation method of the fiber-reinforced PBT composite fusion joint of the present embodiment is carried out according to the following steps:

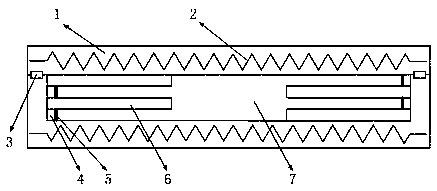

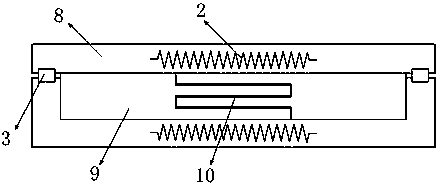

[0032] (1) if figure 1 As shown in Fig. 1, the vacuum-assisted resin diffusion molding process is used to prepare fiber-reinforced PBT composite parts to be connected with convex grooves. Specifically, a porous steel sheet that can move up and down and is covered with a release cloth is arranged on both sides of the vacuum mold cavity. , lay three layers of fiber cloth in the inner cavity of the vacuum mo...

Embodiment 2

[0039]The fiber cloth used in this example is a unidirectional glass fiber cloth with a single layer thickness of 0.2 mm produced by Yixing Fuxing Glass Fiber Co., Ltd.; Tin chloride; the CBT resin used is the resin model CBT100 produced by Cyclics Company of the United States, and it was dried in a vacuum oven at 105° C. for 10 h before use.

[0040] The preparation method of the fiber-reinforced PBT composite fusion joint of the present embodiment is carried out according to the following steps:

[0041] (1) if figure 1 As shown in Fig. 1, the vacuum-assisted resin diffusion molding process is used to prepare fiber-reinforced PBT composite parts to be connected with convex grooves. Specifically, a porous steel sheet that can move up and down and is covered with a release cloth is arranged on both sides of the vacuum mold cavity. , lay three layers of glass fiber cloth in the inner cavity of the vacuum mold, no fiber cloth is laid on the steel sheet, and resistance wires are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com