Mono-dispersed nitrogen doped hollow carbon nano polyhedron and preparation method thereof

A nitrogen-doped, monodisperse technology, applied in the direction of nano-carbon, can solve the problems of inability to directly prepare hollow-structure carbon nanomaterials, and achieve the effect of maintaining polyhedral morphology, uniform nitrogen doping, and environmentally friendly preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

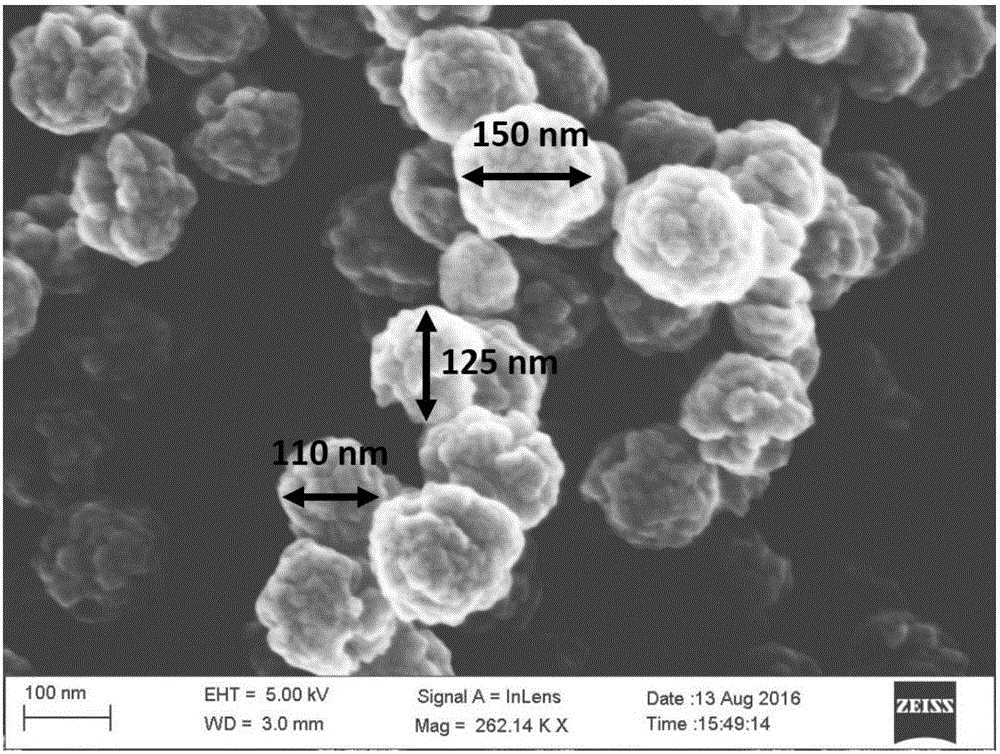

[0033] (1) Preparation of ZnO nanospheres

[0034] Add 40mL of 0.1mol / L zinc acetate aqueous solution and 200mL of 0.1mol / L triethanolamine aqueous solution into a 250mL Erlenmeyer flask, stir at room temperature for 30min, and then irradiate it in a water bath at 20℃ ultrasonically for 20min. Set 12h. ZnO nanospheres are obtained by centrifugal collection, washing, and vacuum drying.

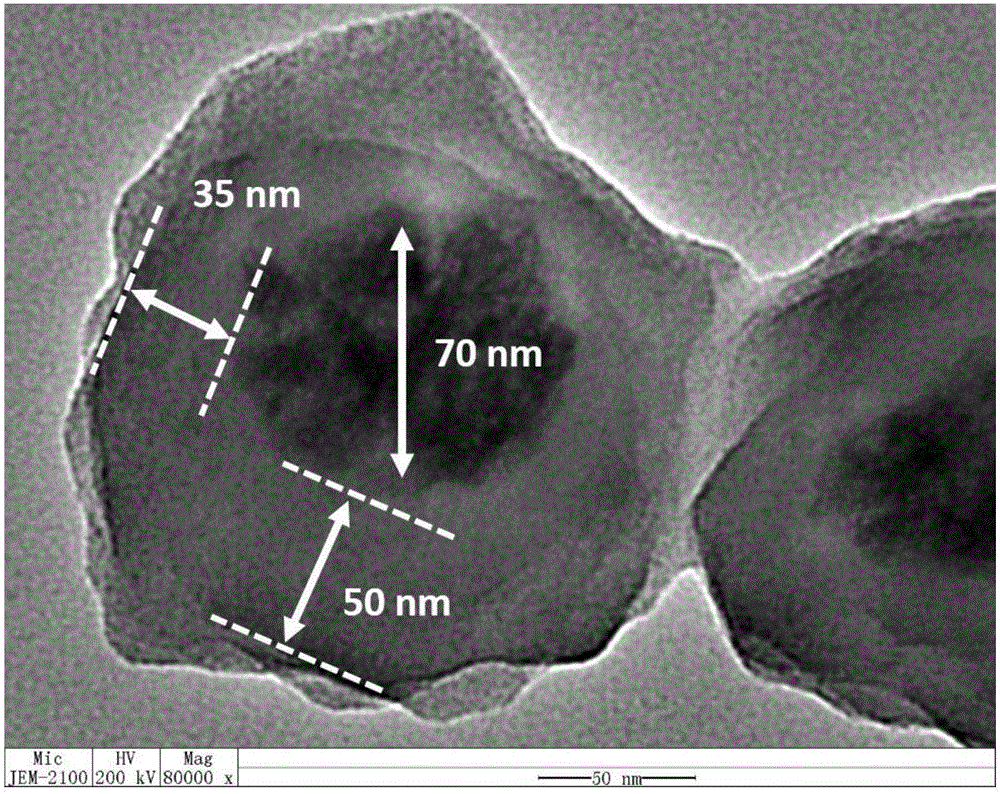

[0035] (2) Preparation of ZnO@ZIF-8 precursor with core-shell structure

[0036] Add 40.0mg of ZnO nanospheres obtained in step 1) into a 40ml glass bottle containing a mixed solvent of DMF and water (32mL, volume ratio 3:1), and ultrasound for 10min at room temperature to fully diffuse, and then add 0.33g 2-formaldehyde After sonicating for 5 minutes, the glass bottle was tightly capped and placed in a 50°C oven for 6 hours. After the reaction, the product was centrifuged, washed, and vacuum dried to obtain a core-shell structure ZnO@ZIF-8 precursor.

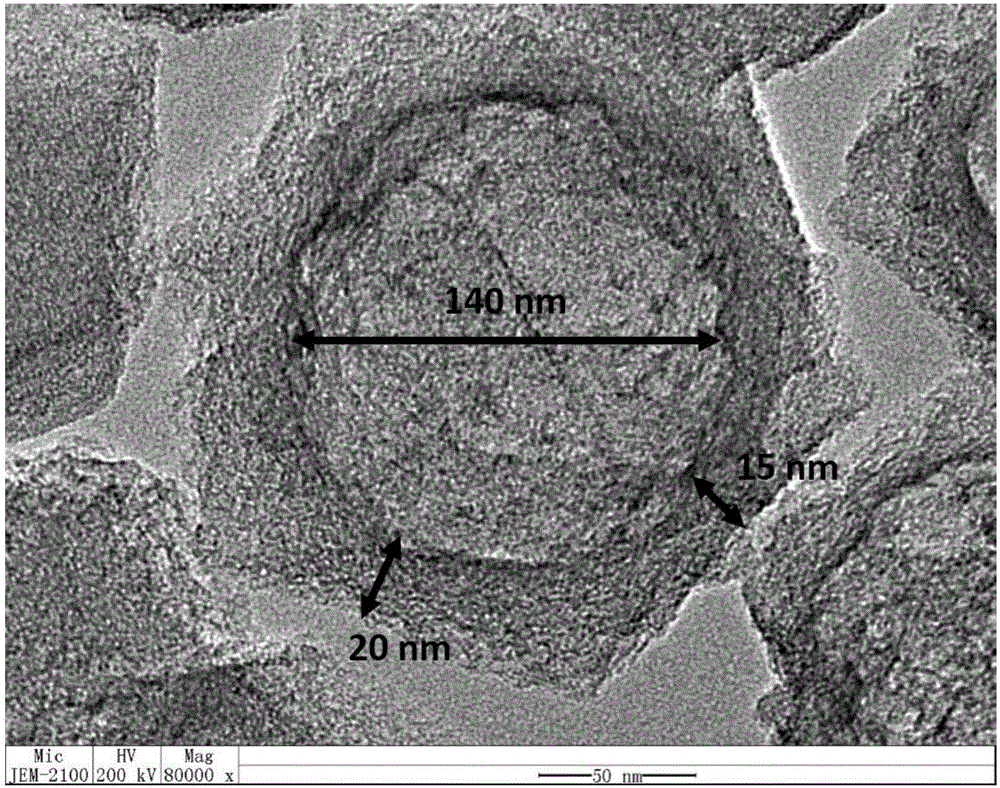

[0037] (3) Preparation of monodisperse nitrogen...

Embodiment 2

[0042] (1) Preparation of ZnO nanospheres

[0043] Add 40mL of 0.1mol / L zinc acetate aqueous solution and 200mL of 0.2mol / L triethanolamine aqueous solution into a 250mL Erlenmeyer flask, stir at room temperature for 30min, and then irradiate it in a water bath at 50℃ ultrasonically for 20min, then statically Set 12h. ZnO nanospheres are obtained by centrifugal collection, washing, and vacuum drying.

[0044] (2) Preparation of ZnO@ZIF-8 precursor with core-shell structure

[0045] Add 40.0mg of ZnO nanospheres obtained in step 1) into a 40ml glass bottle containing a mixed solvent of DMF and water (32mL, volume ratio 3:1), and ultrasound for 10min at room temperature to fully diffuse, and then add 0.33g 2-formaldehyde After sonicating for 5 minutes, the glass bottle is tightly capped and placed in an oven at 70°C for 4 hours. After the reaction is completed, the product is centrifuged, washed, and vacuum dried to obtain a core-shell structure ZnO@ZIF-8 precursor.

[0046] (3) Prepa...

Embodiment 3

[0049] (1) Preparation of ZnO nanospheres

[0050] Add 40mL of 0.1mol / L zinc acetate aqueous solution and 200mL of 0.1mol / L triethanolamine aqueous solution into a 250mL Erlenmeyer flask, stir at room temperature for 30min, and then irradiate it in a water bath at 50℃ ultrasonically for 20min, then statically Set 12h. ZnO nanospheres are obtained by centrifugal collection, washing, and vacuum drying.

[0051] (2) Preparation of ZnO@ZIF-8 precursor with core-shell structure

[0052] Add 40.0mg of ZnO nanospheres obtained in step 1) into a 40ml glass bottle containing a mixed solvent of DMF and water (32mL, volume ratio 2:1), ultrasonically at room temperature for 10 minutes to fully diffuse, and then add 0.66g 2-formaldehyde After sonicating for 5 minutes, the glass bottle was tightly capped and placed in an oven at 50°C for 4 hours. After the reaction, the product was centrifuged, washed, and vacuum dried to obtain the core-shell structure ZnO@ZIF-8 precursor.

[0053] (3) Preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com