Cobalt phosphide/graphene/N-doped carbon composite material and method for preparing same

A technology of carbon composite materials and graphene, which is applied in the direction of electrochemical generators, active material electrodes, structural parts, etc., can solve problems such as the inability to form a three-dimensional conductive network structure, the inability to compound graphene, and poor stability during use, etc., to achieve The preparation process is simple and feasible, with excellent lithium storage performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

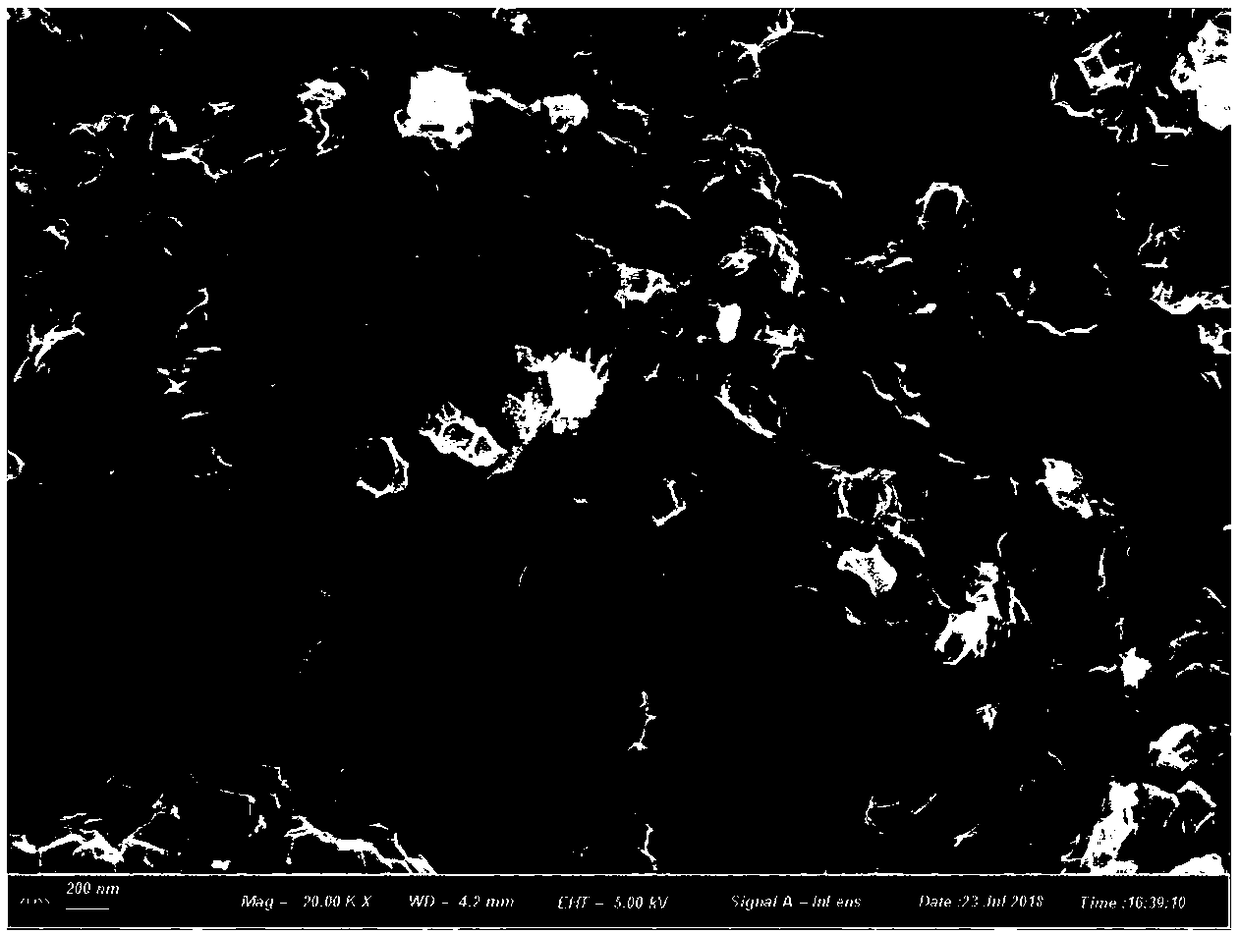

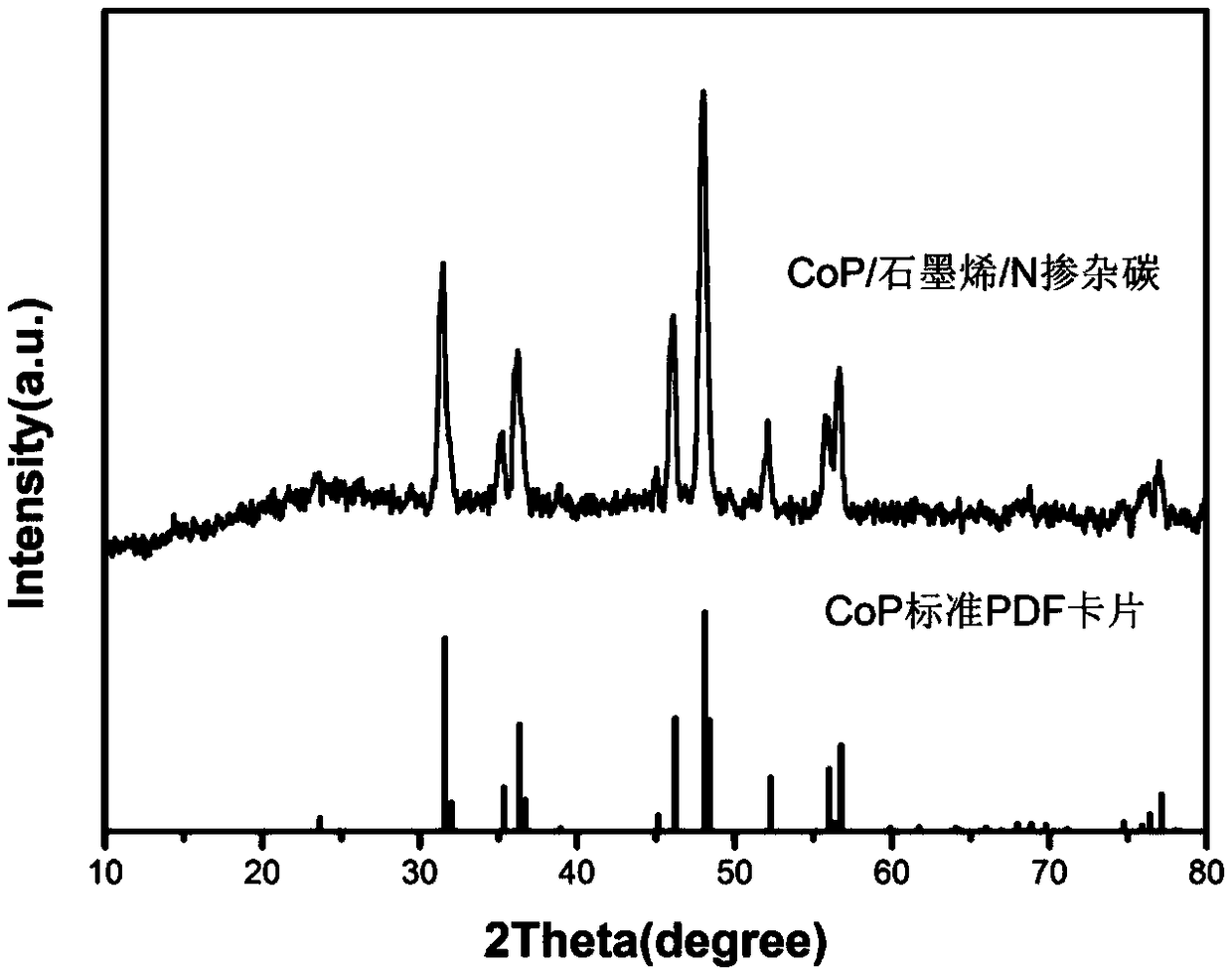

[0025] A method for preparing polyhedral cobalt phosphide / graphene / N-doped carbon composite materials based on MOFs templates, comprising the following steps:

[0026] 1) Preparation of polyhedral metal-organic framework composite ZIF-67 / graphene composite: Weigh 5.5 mmol Co(NO 3 ) 2 ·6H 2 O, 30mg graphene and 300mg PVP (K30), dissolved in 100ml of methanol and ultrasonically dispersed for 30min, weighed 45mmol 2-methylimidazole, dissolved in 100ml of methanol, after stirring completely dissolved, the Co(NO 3 ) 2 ·6H 2 Pour the O solution into the 2-methylimidazole solution, set the stirring speed at 350 rpm, stir for 12 minutes, stop stirring and aging at room temperature for 20 hours, put the product in a centrifuge, set the centrifugal speed at 15000 rpm, and centrifuge for 5 minutes Carry out centrifugation, collect the precipitate and wash it with methanol three times, and then place it at 60°C for 12 hours in a vacuum. The product obtained is a polyhedral metal-organ...

Embodiment 2

[0031] A method for preparing polyhedral cobalt phosphide / graphene / N-doped carbon composite materials based on MOFs templates, comprising the following steps:

[0032] 1) Preparation of polyhedral metal-organic framework composite ZIF-67 / graphene composite: Weigh 5.5 mmol Co(NO 3 ) 2 ·6H 2 O, 15mg graphene and 150mg PVP (K30), dissolved in 100ml of methanol and ultrasonically dispersed for 30min, weighed 45mmol 2-methylimidazole, dissolved in 100ml of methanol, after stirring completely dissolved, the Co(NO 3 ) 2 ·6H 2 Pour the O solution into the 2-methylimidazole solution, set the stirring speed to 400 rpm, stir for 15 minutes, stop stirring and then age at room temperature for 20 hours, put the product in a centrifuge, set the centrifugal speed to 16000 rpm, and centrifuge for 3 minutes Carry out centrifugation, collect the precipitate and wash it with methanol three times, and then place it at 60°C for 12 hours in a vacuum. The product obtained is a polyhedral metal-or...

Embodiment 3

[0037] A method for preparing polyhedral cobalt phosphide / graphene / N-doped carbon composite materials based on MOFs templates, comprising the following steps:

[0038] 1) Preparation of polyhedral metal-organic framework composite ZIF-67 / graphene composite: Weigh 5.5 mmol Co(NO 3 ) 2 ·6H 2 O, 40mg graphene and 400mg PVP (K30), dissolved in 100ml of methanol and ultrasonically dispersed for 30min, weighed 45mmol 2-methylimidazole, dissolved in 100ml of methanol, after stirring to dissolve completely, the Co(NO 3 ) 2 ·6H 2 Pour the O solution into the 2-methylimidazole solution, set the stirring speed at 300 rpm, stir for 20 minutes, stop stirring and aging at room temperature for 20 hours, put the product in a centrifuge, set the centrifugal speed at 12000 rpm, and centrifuge for 7 minutes Carry out centrifugation, collect the precipitate and wash it with methanol three times, and then place it at 60°C for 12 hours in a vacuum. The product obtained is a polyhedral metal-org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com