A method of hydrothermally preparing samarium borate nanowires

A technology of nanowires and samarium borate, applied in the field of nanomaterial preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

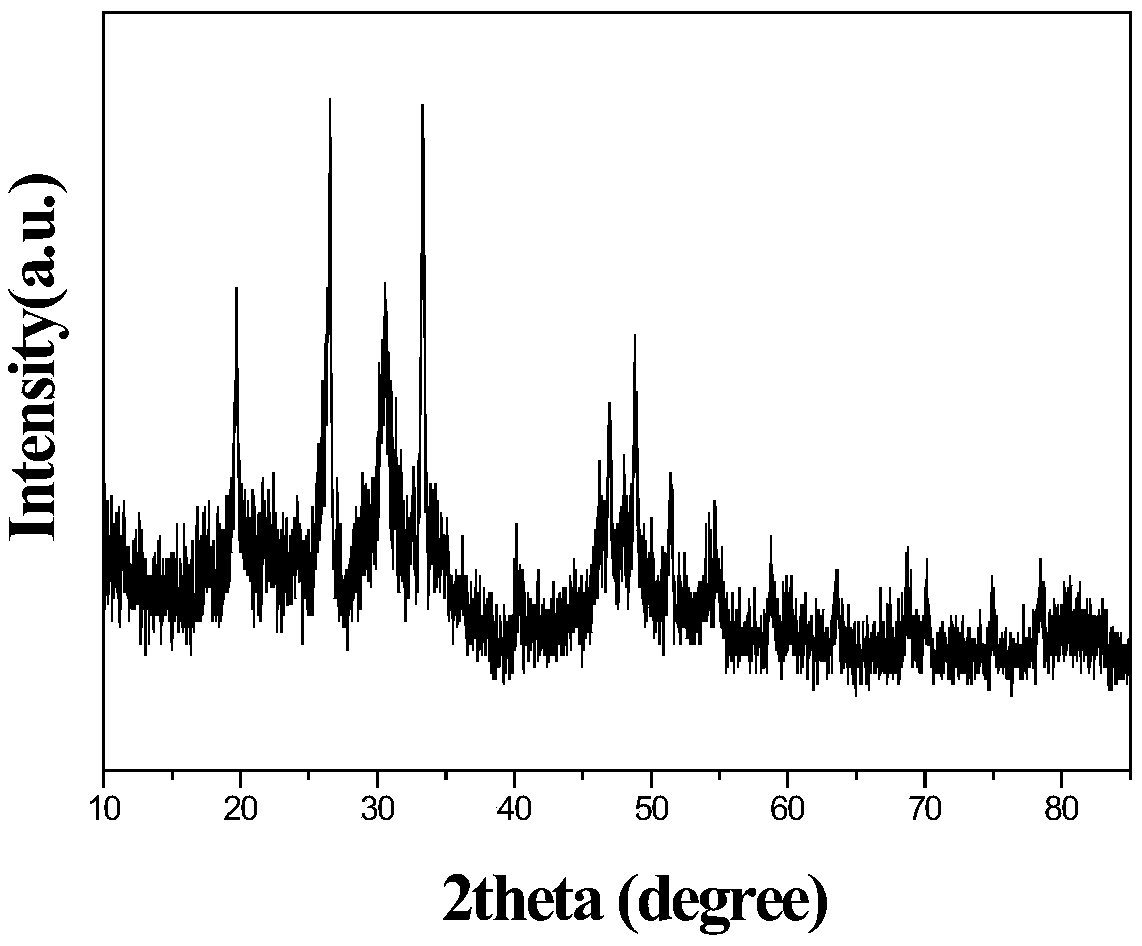

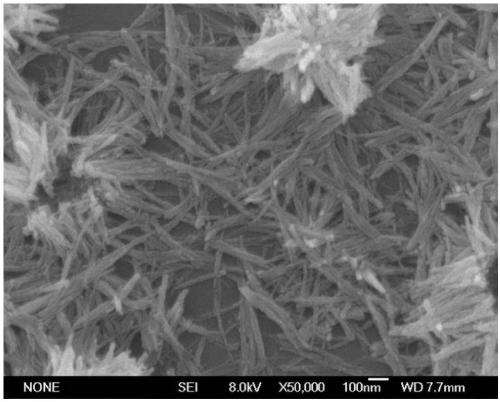

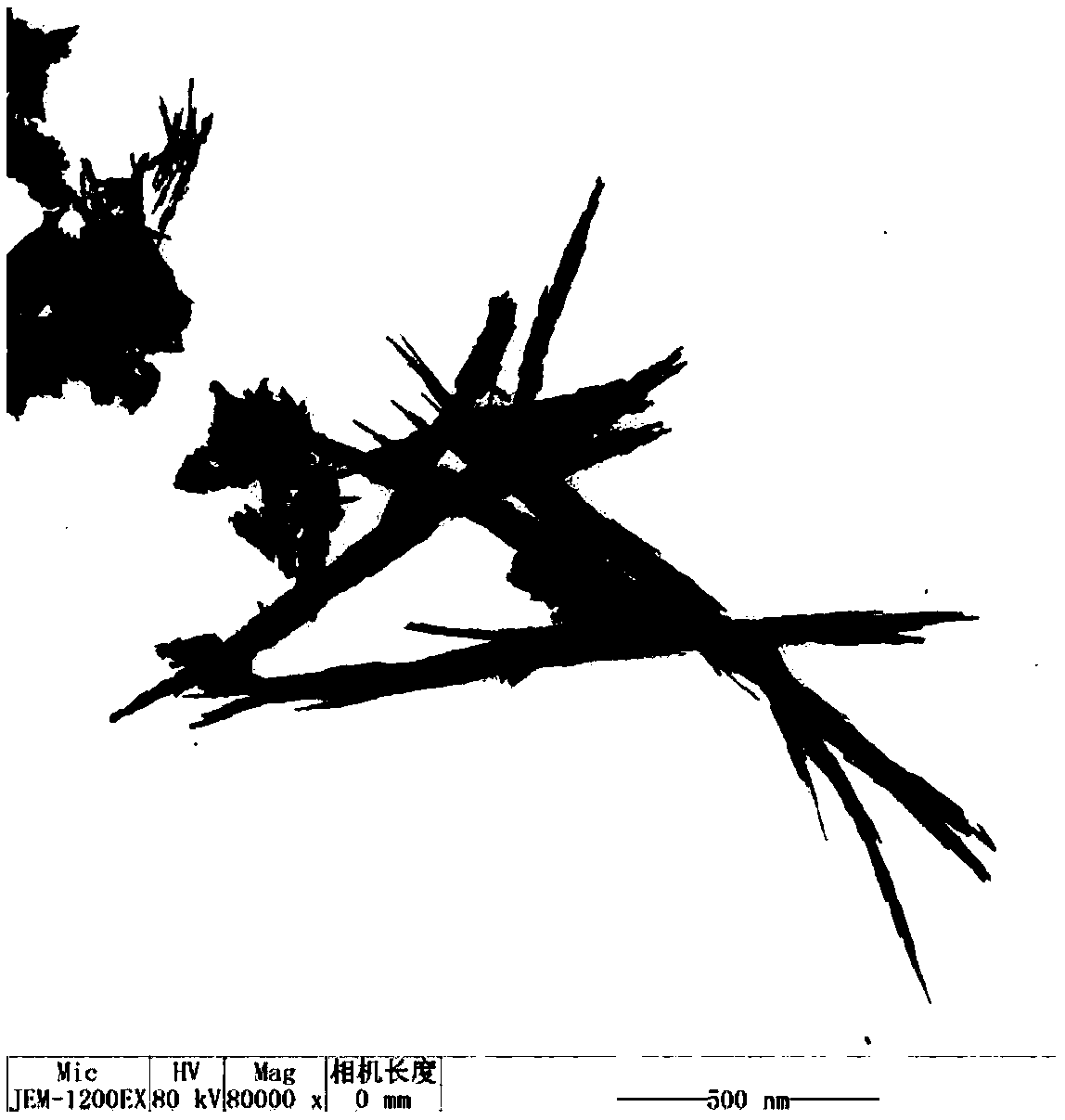

[0021] Measure 30ml of 0.08M Sm(NO 3 ) 3 Solution, add 0.2g of sodium oleate, ultrasonically dissolve, add 40ml of 0.08M borax solution dropwise, stir for 1h, transfer to a reaction kettle, react at 200°C for 16h, centrifuge and wash the obtained product. The structural characteristics and performance characteristics of gained samarium borate are as follows figure 1 , figure 2 , image 3 , Figure 4 shown.

Embodiment 2

[0023] Measure 30ml of 0.08M Sm(NO 3 ) 3 Solution, add 0.2g of sodium oleate, ultrasonically dissolve, add 40ml of 0.08M borax solution dropwise, stir for 1h, transfer to a reaction kettle, react at 200°C for 8h respectively, centrifuge and wash the obtained product. The structural characteristics of gained samarium borate are as Figure 5 , Image 6 shown.

Embodiment 3

[0025] Measure 30ml of 0.08M Sm(NO 3 ) 3 The solution was ultrasonically dissolved, and 40ml of 0.08M borax solution was added dropwise, stirred for 1h, transferred to a reaction kettle, and reacted at 200°C for 8h respectively, and the obtained product was centrifuged and washed. The structural characteristics of gained samarium borate are as Figure 7 , Figure 8 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com