A kind of binary composite water flooding degreasing agent and preparation method thereof

A binary compound flooding and degreaser technology, which is applied in separation methods, flocculation/sedimentation water/sewage treatment, mining wastewater treatment, etc., can solve the problem of single degreaser composition, increased sewage viscosity, and oil droplet particle size change. Small and other problems, to achieve the effect of meeting environmental protection, promoting flocculation increase, and low addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Degreaser G 1 and its preparation method

[0031] (1) Degreaser G 1 The composition, components and molecular formula are as follows:

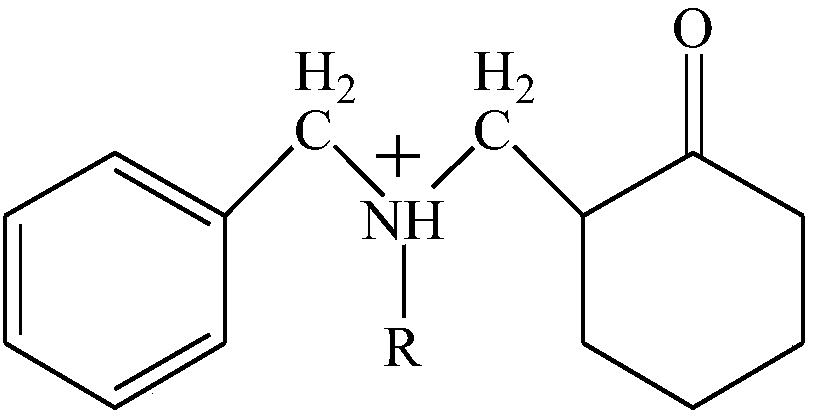

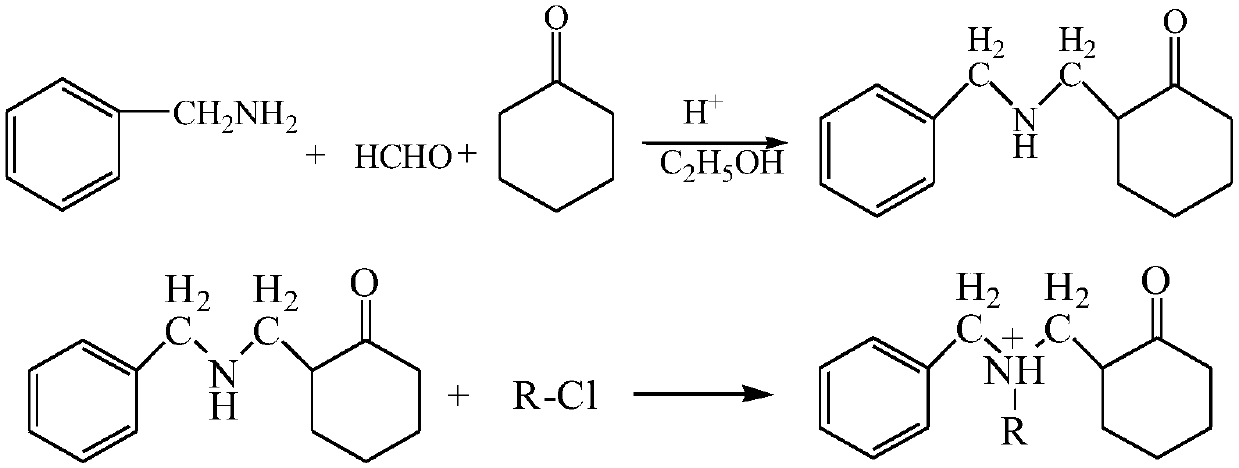

[0032] Degreaser G 1 It is obtained by reacting benzylamine, formaldehyde, cyclohexanone and chloroalkane according to the molar ratio of 1:5:1.2:2.5, and the molecular formula is as follows:

[0033]

[0034] where R is C 8 straight-chain alkanes.

[0035] (2) Degreaser G 1 The preparation method is as follows:

[0036] ① Add 1 mol of benzylamine to a three-necked flask equipped with an electric stirrer, a reflux condenser, and a thermometer, then add 10 mol of ethanol as a solvent, heat up to 40°C, stir for 10 min at a stirring rate of 300 rpm, and then add 1.2 mol of cyclic For hexanone, the temperature was raised to 65 ° C, the stirring rate was 400 rpm, the temperature was lowered to 30 ° C after continuous stirring for 20 minutes, and then the pH value was adjusted to 2 with 15% hydrochloric acid to obtain ...

Embodiment 2

[0040] Embodiment 2: Degreaser G 2 and its preparation method

[0041] (1) Degreaser G 2 The composition, components and molecular formula are as follows:

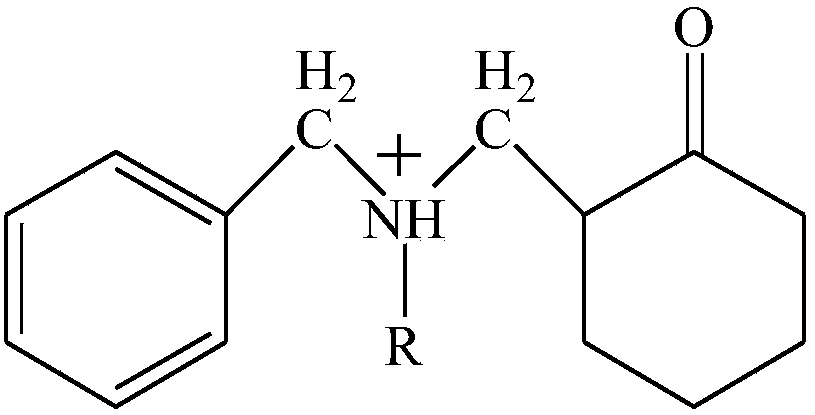

[0042] Degreaser G 2 It is obtained by reacting benzylamine, formaldehyde, cyclohexanone and chloroalkane according to the molar ratio of 1:6:1.8:3, and the molecular formula is as follows:

[0043]

[0044] where R is C 9 straight-chain alkanes.

[0045] (2) Degreaser G 2 The preparation method is as follows:

[0046] ① Add 1 mol of benzylamine to a three-necked flask equipped with an electric stirrer, a reflux condenser, and a thermometer, then add 15 mol of ethanol as a solvent, heat up to 40°C, stir for 15 min at a stirring rate of 330 rpm, and then add 1.8 mol of cyclo For hexanone, the temperature was raised to 62 ° C, the stirring rate was 500 rpm, the temperature was lowered to 32 ° C after continuous stirring for 20 minutes, and then the pH value was adjusted to 3 with 15% hydrochloric acid to obtain a m...

Embodiment 3

[0050] Embodiment 3: Degreaser G 3 and its preparation method

[0051] (1) Degreaser G 3 The composition, components and molecular formula are as follows:

[0052] Degreaser G 3 It is obtained by reacting benzylamine, formaldehyde, cyclohexanone and chloroalkane according to the molar ratio of 1:8:1.5:4. The molecular formula is as follows:

[0053]

[0054] where R is C 10 straight-chain alkanes.

[0055] (2) Degreaser G 3 The preparation method is as follows:

[0056] ① Add 1 mol of benzylamine to a three-necked flask equipped with an electric stirrer, a reflux condenser, and a thermometer, then add 18 mol of ethanol as a solvent, heat up to 40°C, stir for 25 min at a stirring rate of 370 rpm, and then add 1.5 mol of cyclic For hexanone, the temperature was raised to 60°C, the stirring rate was 450rpm, the temperature was lowered to 33°C after continuous stirring for 20 minutes, and then the pH value was adjusted to 4 with 15% hydrochloric acid to obtain a mixture ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com