Method for preparing PZT-based composite piezoelectric ceramic and PZT-based composite piezoelectric ceramic

A piezoelectric ceramic and piezoelectric technology, applied in the field of piezoelectric ceramic material preparation, can solve the problems that are not given, not proposed, and reduce the resistance of PZT piezoelectric ceramics, so as to achieve the effect of ensuring sufficient polarization and increasing output current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

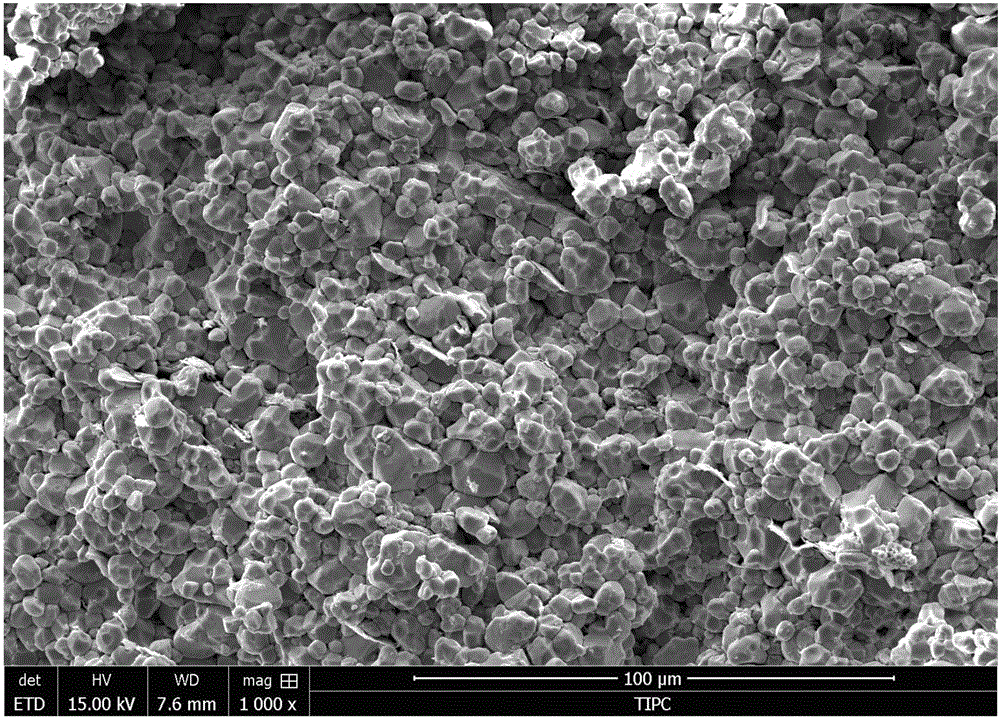

Image

Examples

preparation example Construction

[0030] The preparation method of the PZT-based composite piezoelectric ceramics comprises the following steps:

[0031] (1) Preparation of graphene oxide (GO)

[0032] Synthesize graphene oxide using the modified Hummers method: first perform low-temperature intercalation in an ice-water bath: add an appropriate amount of concentrated sulfuric acid to the container, and then follow the mass ratio of 1:2-4:1 (preferably 2:1) under magnetic stirring Add graphite powder and sodium nitrate, then slowly add potassium permanganate whose mass is 3 times that of graphite powder, stir at 0-6°C for 1-2h, then warm up to room temperature, and continue stirring at room temperature for 1-24h; Then dilute the sample with low temperature (preferably 0-2°C) deionized water, raise the temperature to 90°C and stir for 5-30min, then add an appropriate amount of H 2 o 2 reaction, followed by dilution with deionized water; then repeated washing with appropriate concentrations of HCl and ethanol,...

Embodiment 1

[0043] (1) Preparation of graphene oxide (GO)

[0044] Weigh 6 g of graphite powder, 3 g of sodium nitrate, and 18 g of potassium permanganate, and slowly add 150 ml of concentrated sulfuric acid with a concentration of 98% into the three raw materials successively, and the temperature of the concentrated sulfuric acid is 2° C. After the mixture was kept at 0-2°C and stirred for 60 minutes, the temperature was adjusted to 30°C, and then kept stirring for 120 minutes. Subsequently, 300 ml of deionized water at a temperature of 2° C. was slowly added while increasing the stirring speed. Raise the temperature to 90° C., heat for 5 minutes, and then add 12 ml of 30% hydrogen peroxide. Then add 500ml of deionized water to dilute the acid solution, and the concentration of graphene oxide is about 7.5mg / ml. The above solution was washed twice with 200ml of hydrochloric acid and 200ml of ethanol respectively, and then washed with deionized water until a neutral hydrogel appeared, an...

Embodiment 2

[0055] (1) Preparation of graphene oxide (GO)

[0056] Weigh 5g of expanded graphite powder, 2.5g of sodium nitrate, and 15g of potassium permanganate, and slowly add 120ml of concentrated sulfuric acid with a concentration of 98% to the three raw materials successively, and the temperature of the concentrated sulfuric acid is 0°C. After the mixture was kept at 0-2°C and stirred for 120 minutes, the temperature was adjusted to 35°C, and then kept stirring for 120 minutes. Then slowly add 250ml of deionized water at a temperature of 2°C, while increasing the stirring speed to suppress the generation of air bubbles. After raising the temperature to 90° C., heat the mixture for 30 minutes, and then add 10 ml of 30% hydrogen peroxide. Then add 300ml of deionized water to dilute the acid solution, and the concentration of graphene oxide is about 9mg / ml. The above solution was washed twice with 100ml of hydrochloric acid and 200ml of ethanol respectively, and then washed with deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com