Curable thermosetting resin composition

A solid resin and composition technology, applied in the field of polymer compounds and their preparation, can solve the problems of reducing other properties of the composition, low dielectric constant and dielectric loss factor, etc., and achieve high glass transition temperature, low dielectric constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0021] For various embodiments, the polypolymer has the following three or four structural units:

[0022] The structural unit (I) is:

[0023] The structural unit (II) is:

[0024] The structural unit (III) is:

[0025] The structural unit (IV) is:

[0026] Wherein each m, n, r and s are independently a natural number representing the mole fraction of the corresponding constituent unit in the copolymer, each R is independently hydrogen, an aromatic group or an aliphatic group, and each AR is independently Aromatic group. Structural unit (I), structural unit (II), and structural unit (III) are essential units.

[0027] For various embodiments, the structural unit (I) accounts for 0.1-60wt% of the copolymer, preferably 0.5wt%, 1wt%, 3wt%, 5.5wt%, 10wt%, 11wt%, 15wt%, 20wt%, 40wt% , 50wt%, 60wt% The molar ratio of structural unit (II) to structural unit (III) is 1:1-20:1, preferably 1:1, 2:1, 3:1, 4:1, 5:1, 6:1, 7:1, 8:1, 9:1, 10:1, 11:1, 12:1, 15:1, 16:1, 17:1, 18...

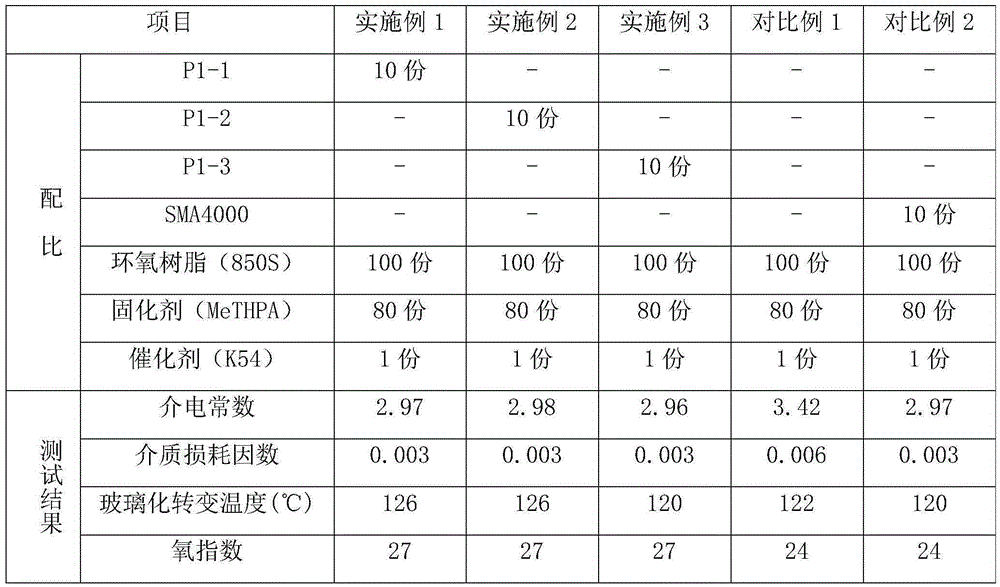

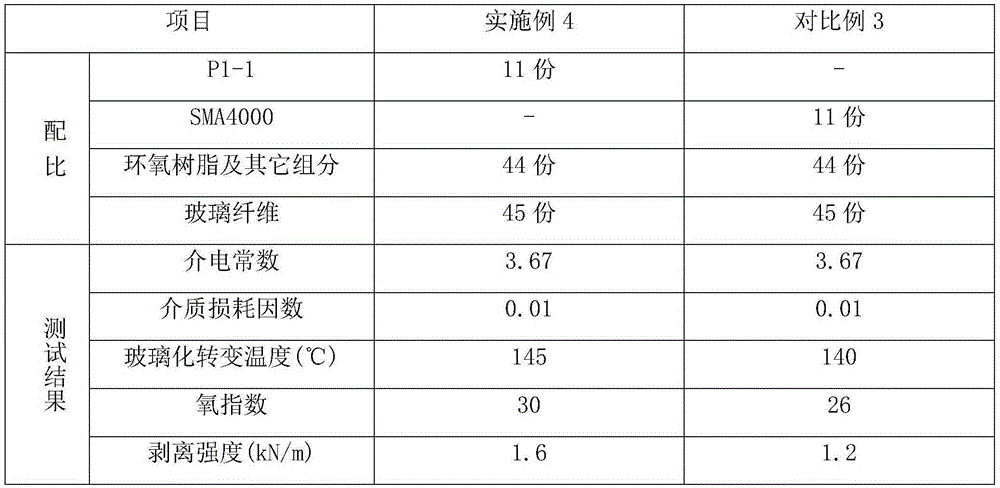

Embodiment

[0040] Below, the present invention is further described in detail through examples. "Parts" mentioned in the Examples of the present invention, unless otherwise specified, means parts by mass.

Synthetic example 1

[0041] Synthesis example 1: Synthesis of multi-component copolymer (P1-1)

[0042] Add 83.3g styrene, 34.6g N-phenylmaleimide, 19.6g maleic anhydride in a 500ml four-necked flask, then add 1.375g initiator BPO and an appropriate amount of chain transfer agent, 200g solvent butanone, 13.75 g PAM-100, heat, stir evenly, control the reaction temperature at 80°C, and react for 6-8 hours. The reactant was distilled under reduced pressure to remove the solvent to obtain a tetrapolymer (P1-1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com