Water-insensitive polyurethane injecting paste material, and preparation method thereof

A grouting material and polyurethane technology, which is applied in the field of polyurethane semi-rigid foam to achieve the effects of high bonding performance, excellent volume stability and high expansion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

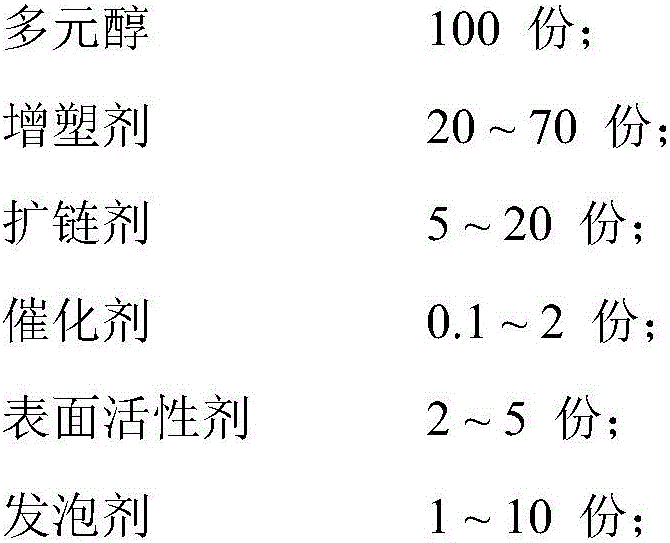

Method used

Image

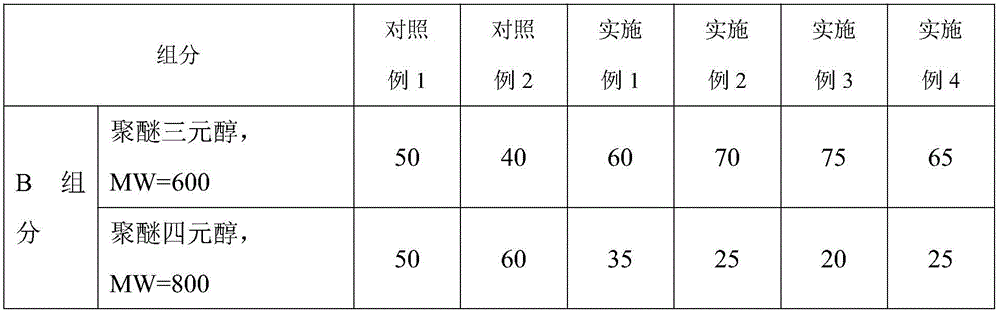

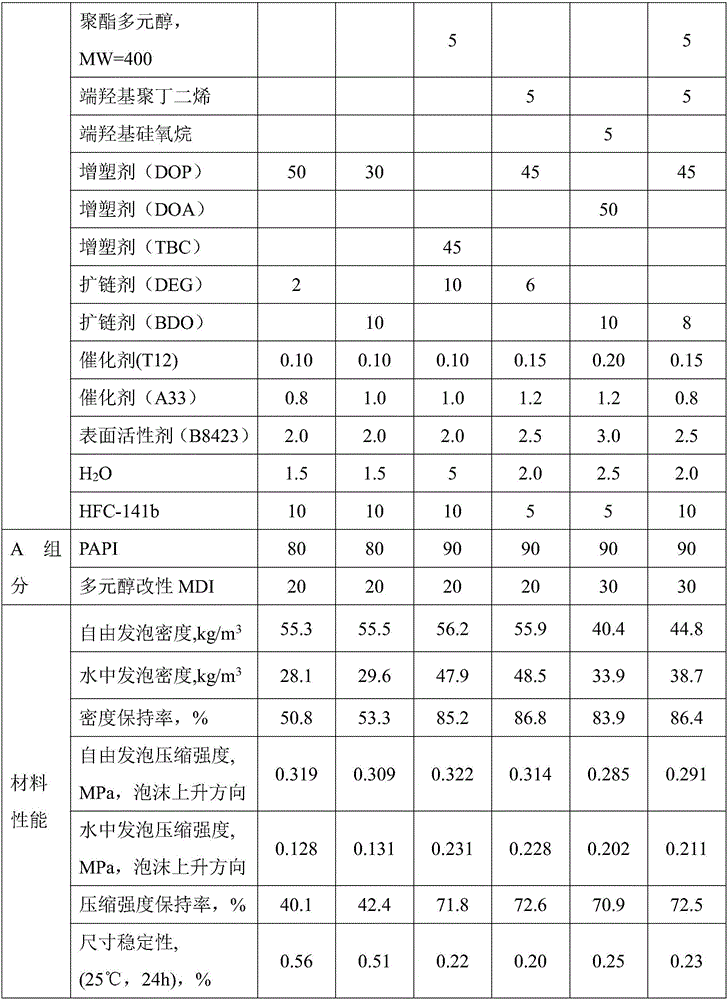

Examples

Embodiment 1-10

[0036] In various embodiments, in the polyphenyl ring aromatic isocyanate:

Embodiment 1

[0037] Example 1: Polymethylene polyphenyl polyisocyanate (PAPI) is provided by Wanhua Company, and the product brand is PM200; in the polyol-modified diphenylmethane diisocyanate, the polyol is a 2-functionality polyether polyol, The molecular weight of PPG is 200;

Embodiment 2

[0038] Example 2: Polymethylene polyphenyl polyisocyanate (PAPI) is provided by Covestro, and the product brand is 44V20; in the polyol-modified diphenylmethane diisocyanate, the polyol is a difunctional polyether polyol , PPG molecular weight is 800;

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com