Carbon-dot-based composite nanomaterials with controllable luminescent properties and their preparation methods and applications

A technology of composite nanomaterials and luminescent properties, applied in the field of materials engineering, can solve the problems of complex preparation process of optical materials, scarcity of preparation raw materials, uncontrollable optical properties, etc., and achieve the effect of simple preparation method, good stability and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

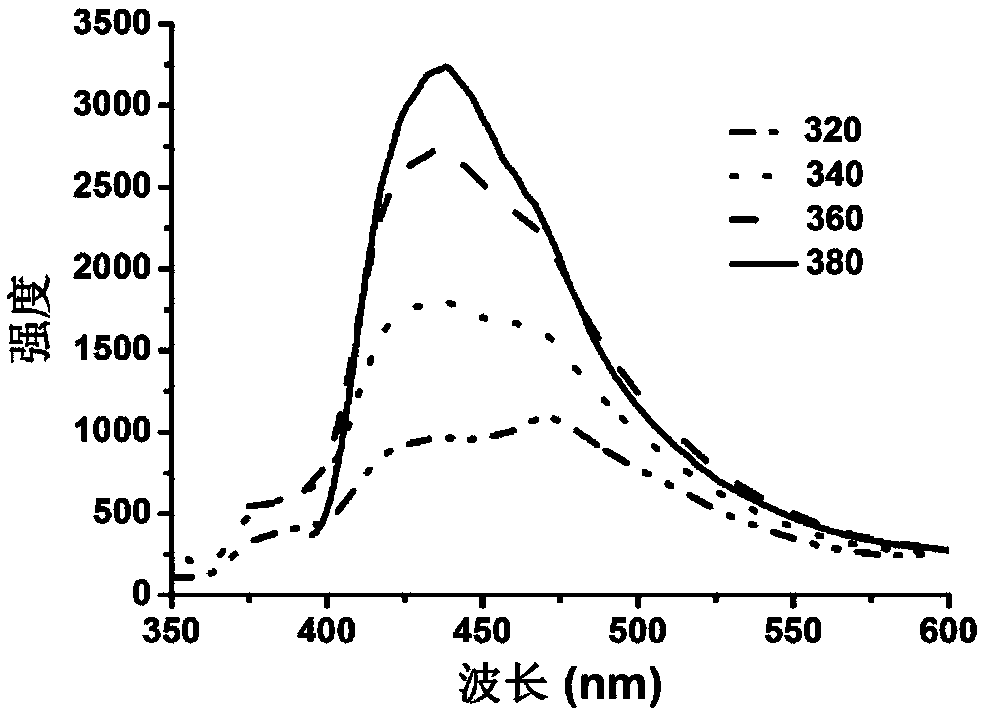

[0040] Example 1 Carbon dot-based composite nanomaterial with controllable luminescence performance and its preparation method

[0041] (1) Preparation of aqueous solution of carbon quantum dots with carboxyl groups on the surface

[0042] 1. Weigh 0.5g of folic acid and 1.0g of citric acid and dissolve them in 50ml of deionized water, stir thoroughly for 10 minutes, then place the obtained mixed solution in a polytetrafluoroethylene high-pressure sealed reaction kettle, and heat at 250°C for 4 hours. get the initial solution;

[0043] 2. Centrifuge the initial solution obtained above at 10,000 rpm for 20 minutes to remove the black precipitate, take the upper layer of brownish-yellow clear liquid, use a dialysis bag with a molecular weight cut-off of 500Da, and dialyze for 24 hours to obtain a pure aqueous solution of fluorescent carbon quantum dots;

[0044] 3. The carbon quantum dot aqueous solution obtained above was freeze-dried for 96 hours to obtain a fluorescent carbo...

Embodiment 2

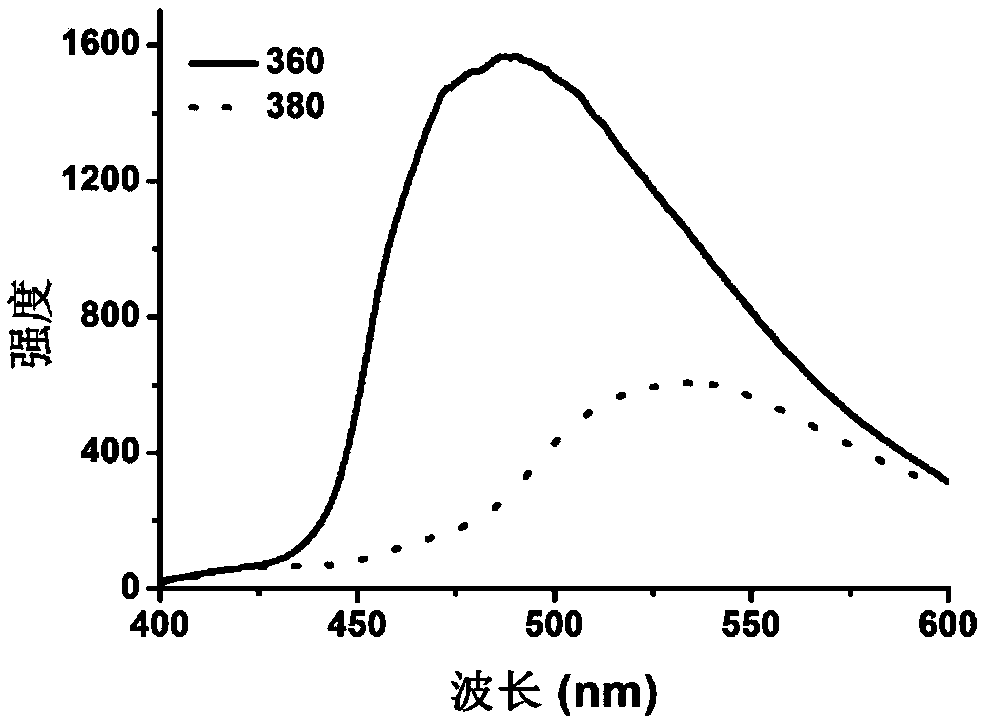

[0056] Example 2 Carbon-dot-based composite nanomaterial with controllable luminescence performance and its preparation method

[0057] (1) Preparation of aqueous solution of carbon quantum dots with carboxyl groups on the surface

[0058] 1. Weigh 0.5g of folic acid and 0.2g of citric acid and dissolve them in 50ml of deionized water, stir thoroughly for 10 minutes, then place the obtained mixed solution in a polytetrafluoroethylene high-pressure sealed tank, and heat it at 240°C with a power of 700w for 4 hour, the initial solution was obtained;

[0059] 2. Centrifuge the initial solution obtained above at 10,000 rpm for 20 minutes to remove the black precipitate, take the upper layer of brownish-yellow clear liquid, use a dialysis bag with a molecular weight cut-off of 500Da, and dialyze for 24 hours to obtain a pure aqueous solution of fluorescent carbon quantum dots;

[0060] 3. The carbon quantum dot aqueous solution obtained above was freeze-dried for 96 hours to obtai...

Embodiment 3

[0072] Example 3 Carbon dot-based composite nanomaterial with controllable luminescence performance and its preparation method

[0073] (1) Preparation of aqueous solution of carbon quantum dots with carboxyl groups on the surface

[0074] 1. Weigh 0.5g of folic acid and 1.0g of citric acid and dissolve them in 50ml of deionized water, stir thoroughly for 10 minutes, then place the resulting mixed solution in a polytetrafluoroethylene high-pressure sealed reaction kettle, and heat at 240°C for 4 hours. get the initial solution;

[0075] 2. Centrifuge the initial solution obtained above at 10,000 rpm for 20 minutes to remove the black precipitate, take the upper layer of brownish-yellow clear liquid, use a dialysis bag with a molecular weight cut-off of 500Da, and dialyze for 24 hours to obtain a pure aqueous solution of fluorescent carbon quantum dots;

[0076] 3. The carbon quantum dot aqueous solution obtained above was freeze-dried for 96 hours to obtain a fluorescent carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com