Method for assembling sample and thermal insulation salt sheet in hole of sample in diamond anvil cell experiment

A technology of diamond counter-anvil and assembly method, which is applied in the preparation, sampling, measuring device and other directions of test samples, can solve problems such as moisture absorption and failure of placing salt tablets, and achieves simple operation, high success rate, and time-saving assembly. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

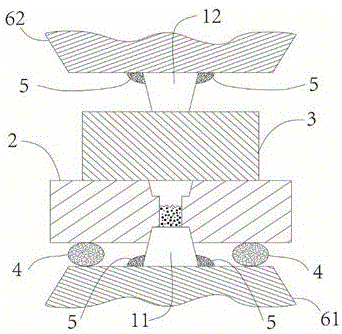

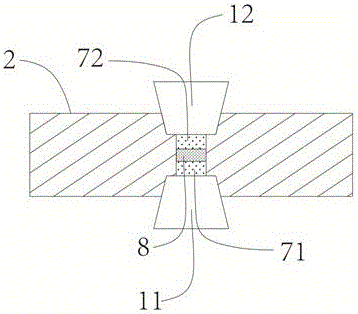

[0028] The assembly method of the present invention will now be described in detail in conjunction with the accompanying drawings.

[0029] A method for assembling a heat-insulating salt sheet and a sample in a diamond-anvil test sample hole is characterized in that the method is carried out sequentially according to the following steps:

[0030] 1) Grinding high-purity dry salt into salt powder;

[0031] 2) Place the pre-processed metal gasket 2 with a through hole on the lower diamond counter-anvil 11, and temporarily fix it with the viscous substance 4 after alignment;

[0032] 3) Fill salt powder into the through hole to 2 / 5-3 / 5 of the through hole volume;

[0033] 4) Place a polymer material sheet 3 whose thickness is 2-5 times the height of the through hole on the upper surface of the through hole, and ensure that the through hole is completely covered by the polymer material sheet 3;

[0034] 5) see figure 1 , contacting the upper diamond anvil 12 with the polymer ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com