Flexible passive and wireless surface acoustic wave sensor and preparing method thereof

A surface acoustic wave, passive wireless technology, used in material analysis, instruments, and scientific instruments using sonic/ultrasonic/infrasonic waves, which can solve the problems of limited flexible piezoelectric films, complex and harsh preparation processes, and lattice mismatches. , to achieve the effect of protection from damage, wide application prospects and high crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

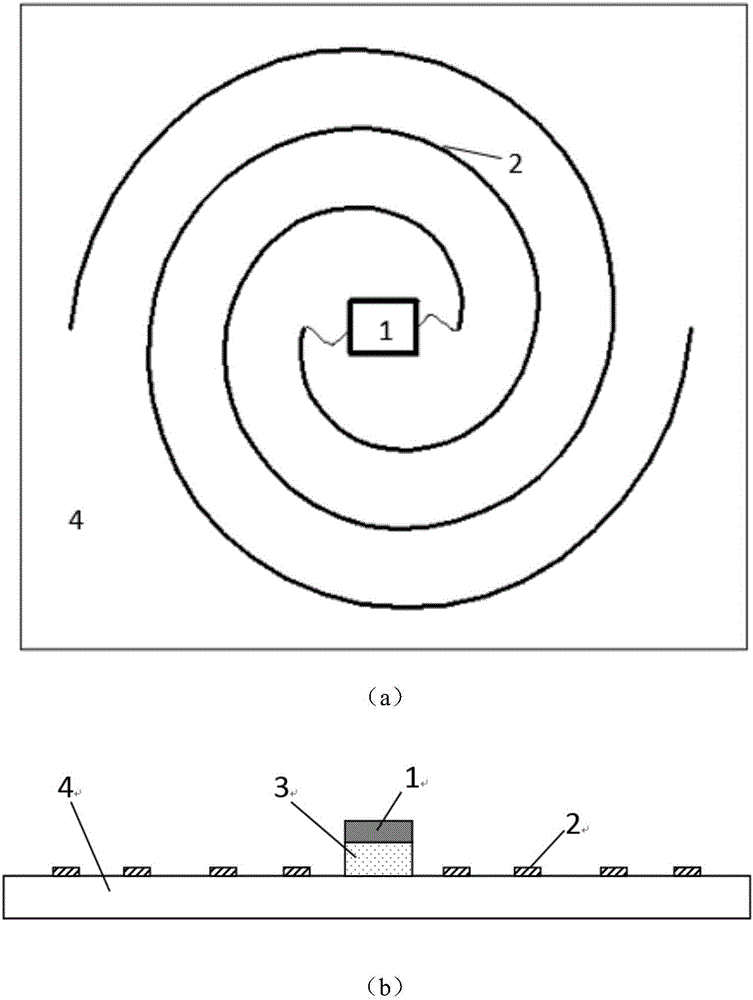

[0047] Such as figure 1 As shown, the flexible passive wireless surface acoustic wave sensor of this embodiment includes: a SAW sensor 1, a planar helical antenna 2, a strain isolator 3 and a flexible substrate 4; wherein, the middle of the flexible substrate 4 is provided with a strain isolator 3; SAW The sensor 1 is printed on the surface of the strain isolator 3 through an adhesive layer; on the surface of the flexible substrate and around the strain isolator, a planar helical antenna 2 is printed; the shape of the planar helix antenna is two plane symmetrical spirals The wires surround the SAW sensor; the SAW sensor 1 and the planar helical antenna 2 are electrically connected.

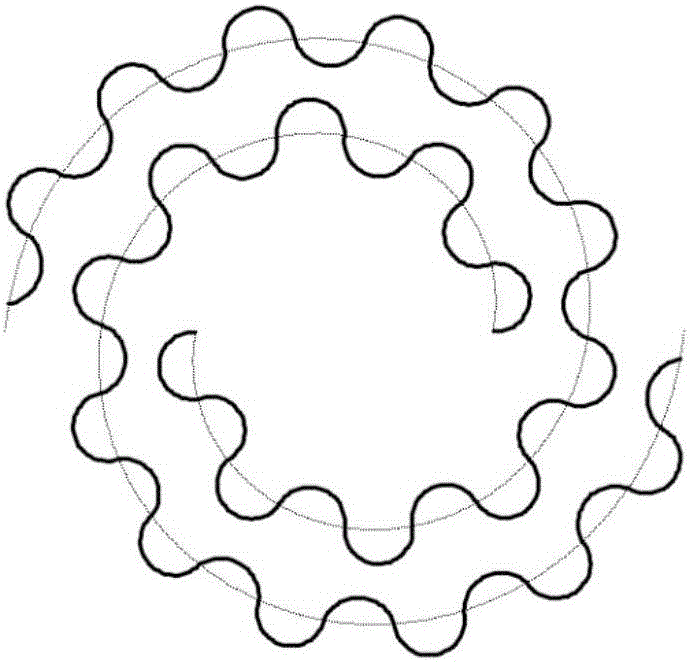

[0048] Further, the planar helical antenna can be bent into a forward waveform on the basis of the helix, such as figure 2 shown.

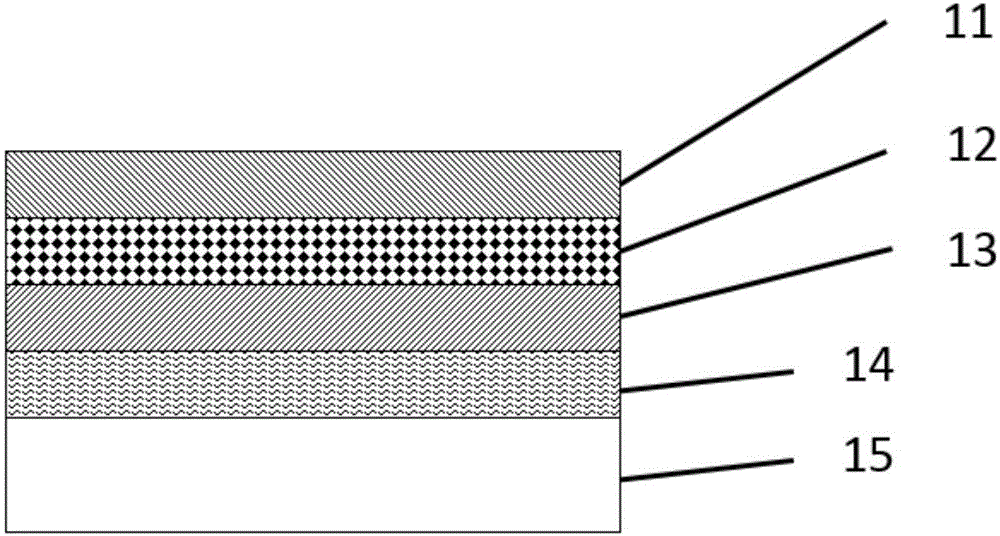

[0049] In this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com