Metal nanoparticle-insulator composite material grating coupler

A metal nanoparticle and grating coupler technology, applied in the field of nanophotonics, can solve the problems of too large grating constant, unable to strongly guide waves in plane waveguide, unable to meet matching conditions, etc., and achieve the effect of high coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The description in this part is for demonstration and explanation, and should not be regarded as a limitation of the technical content disclosed in the present invention.

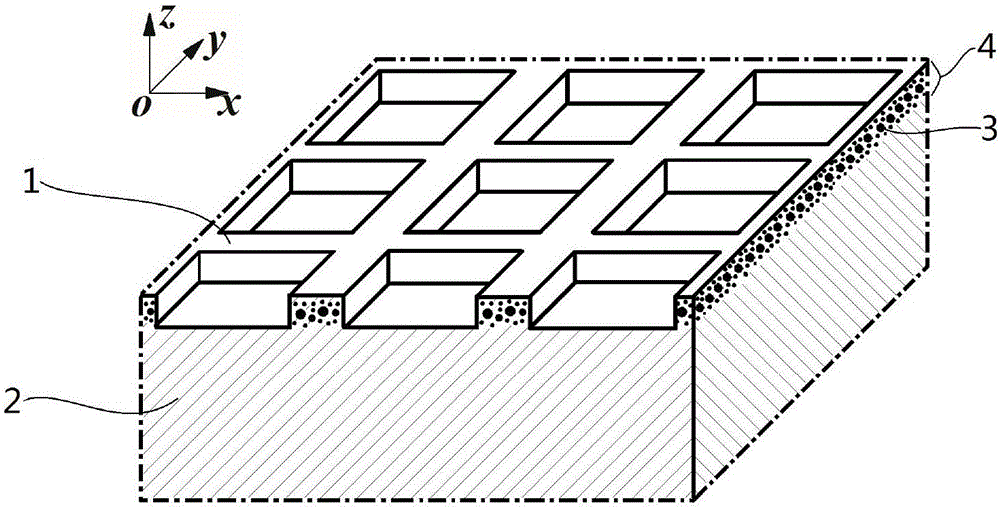

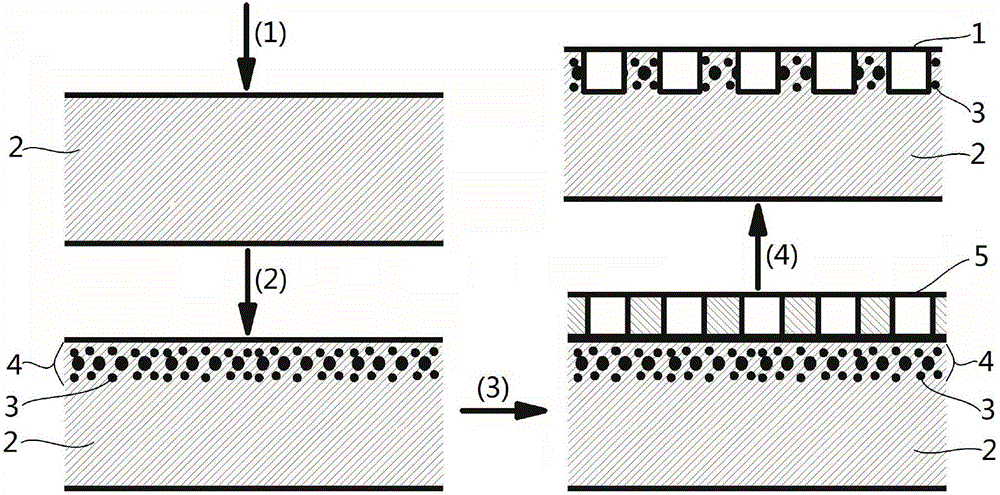

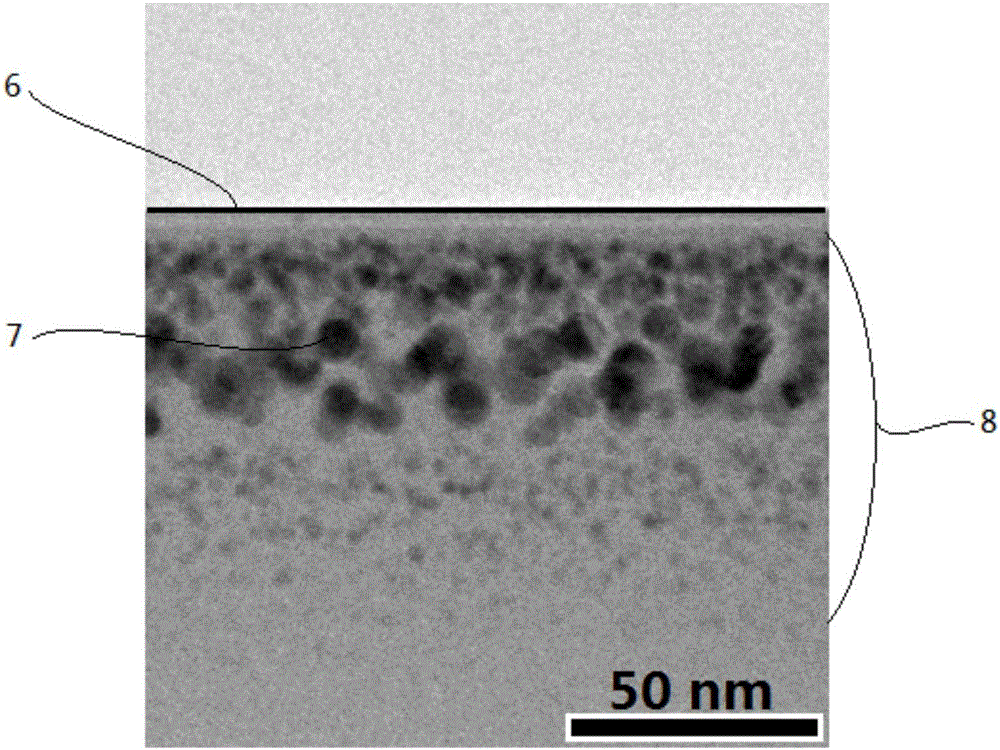

[0041] The structure of the metal nanoparticle-insulator composite grating coupler described in the present invention is as follows: figure 1 As shown, it is composed of a metal nanoparticle-insulator composite material coupling grating 1 and an insulator optical plane waveguide 2 . The metal nanoparticle-insulator composite material coupling grating 1 is a two-dimensional orthogonal rectangular diffraction grating with a thickness of 40-150nm, located on the surface of the insulator optical planar waveguide 2 and formed by implanting metal ions into the metal nanoparticle-insulator composite material modification. In the active layer 4, there is no obvious interface with the insulato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com