MEMS optical switch module with N*N channels

An optical switch and channel technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of unpractical application, long switching time, large insertion loss, etc., and achieve the effect of light weight, compact structure and low insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

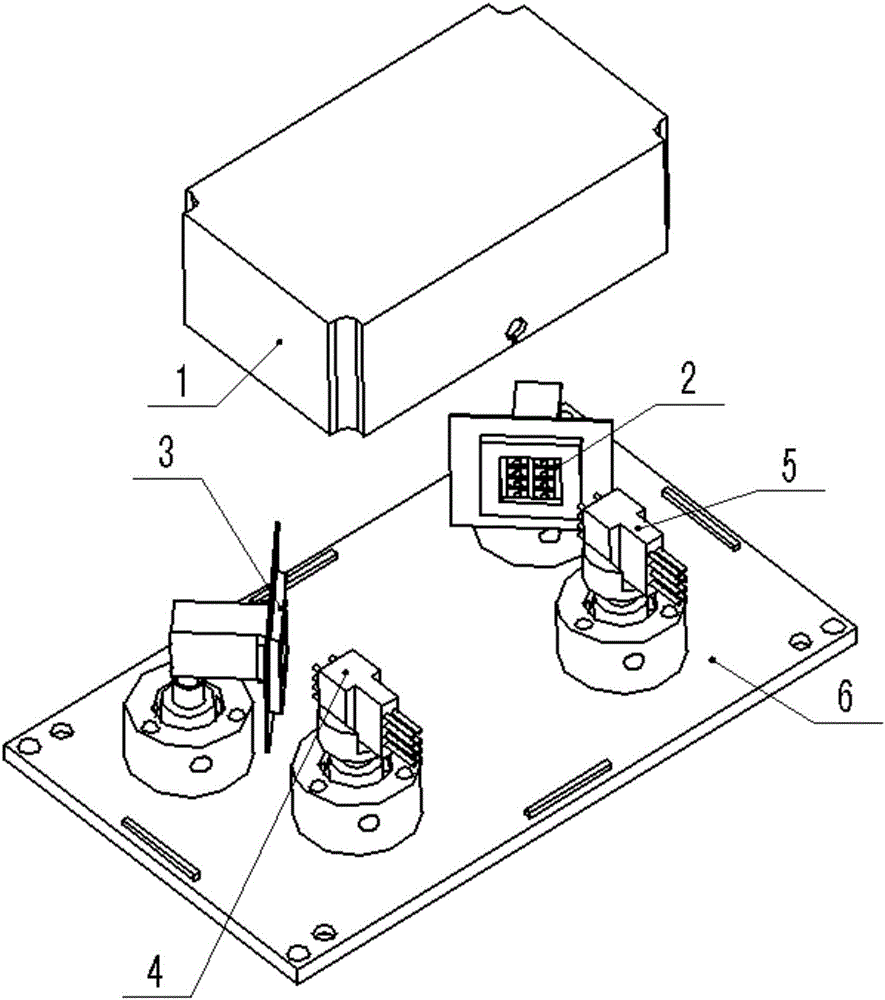

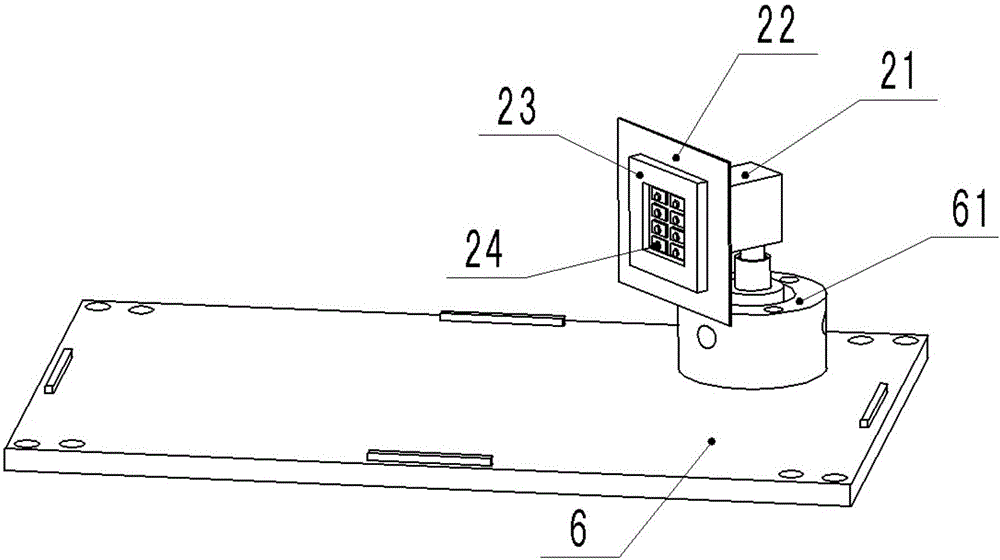

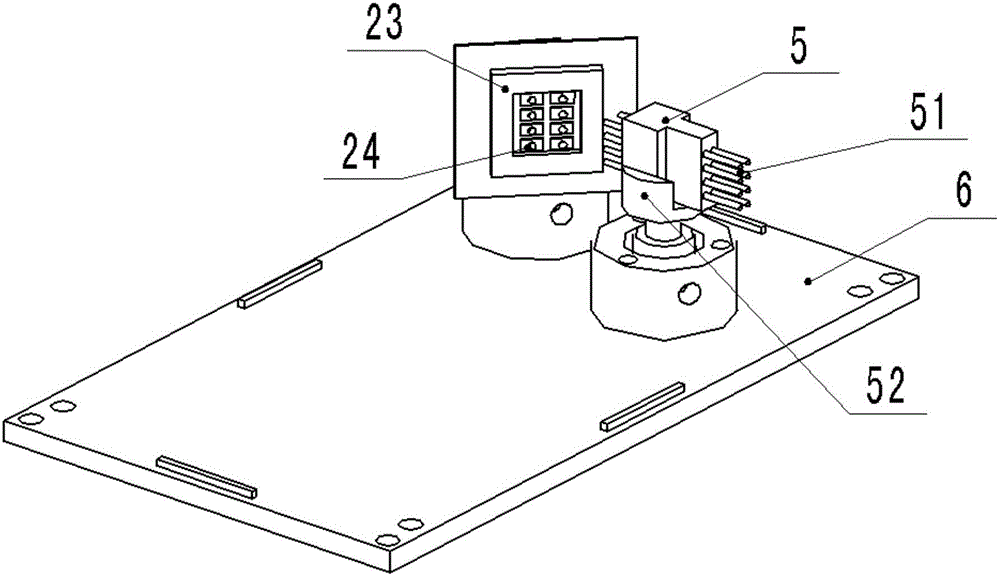

[0027] The MEMS optical switch module embodiment of this N * N channel is the MEMS optical switch module of 8 * 8 channels, such as Figures 1 to 3 As shown, two identical MEMS chips and two identical 8-core collimators are mounted on the same substrate 6 at the same height. The MEMS chip in this example contains 8 micro-mirror mirrors, and the 8 mirrors are arranged in a 2×4 rectangular array on the same plane, which is matched with the 2×4 array of 8-core collimator and 8 optical fibers.

[0028] In this example, two 8-core collimators are parallel to each other, one of which is the first 8-core collimator 5, and its 8 optical fibers are input optical fibers 51, and the 8 lenses matching the input optical fibers 51 are arranged in a plane 2×4 matrix, This plane is perpendicular to the substrate 6; the other is the second 8-core collimator 4, and its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com