Secondary battery electrode material, preparation method and use thereof

A technology of secondary batteries and electrode materials, applied in the field of materials, can solve the problems of low specific capacity and low working voltage of positive electrode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 of the present invention provides a class of electrode materials for secondary batteries, whose general chemical formula is:

[0040] Li x C y B z D. w ;

[0041] Wherein, C is carbon; B is an element for doping and replacing Li, including any one or more of Na, K, Be, Mg, Ca, Al; D is an element for doping and replacing C, including Any one or more of Si, B, N, P, As, O, S; x, y, z, w are respectively used to represent the atomic ratio of the corresponding element; the x, y, z, w Satisfy: 0≤x+z, y+w≤3, 0≤x, y, z, w≤3.

[0042] It should be noted that the electrode material Li x C y B z D. w The doping substituting element B in can replace part or all of Li; the D element can replace part or all of C; B and D can replace only one element or two elements at the same time.

[0043]The electrode materials provided by the embodiments of the present invention are mainly used in lithium-ion secondary batteries, and can also be used in secondary batterie...

Embodiment 2

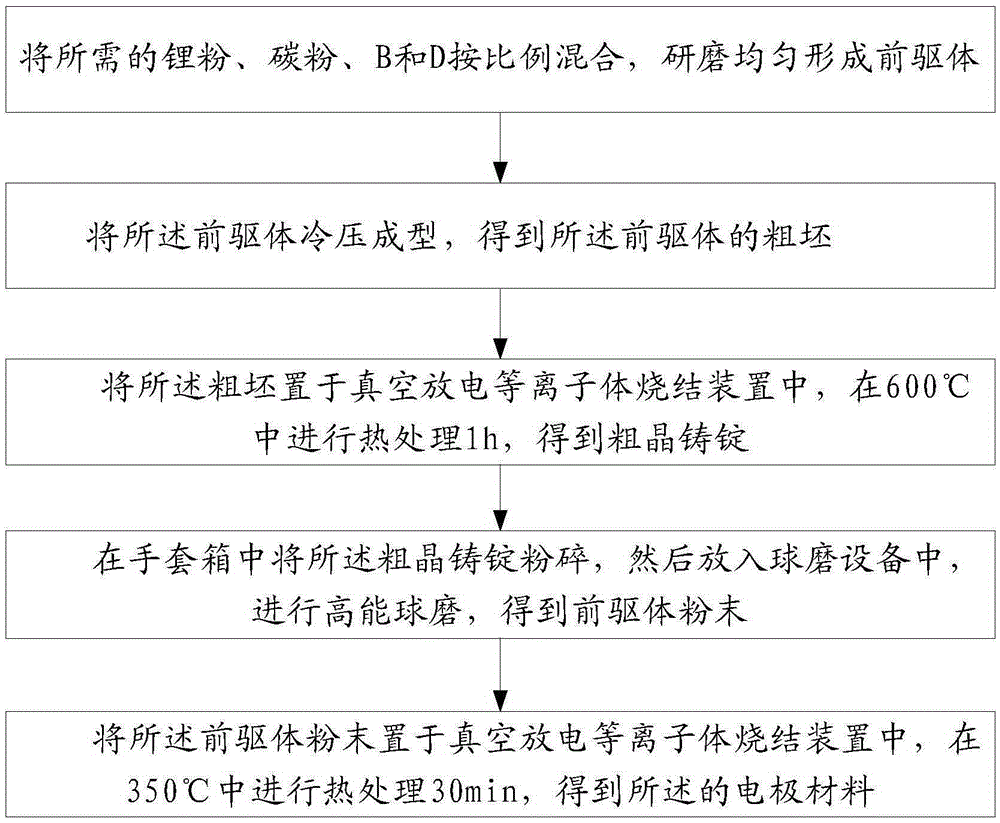

[0045] This embodiment provides a preparation method of a type of electrode material for a secondary battery, specifically a discharge plasma sintering method, such as figure 1 shown, including:

[0046] Mix the required lithium powder, carbon powder, B and D in proportion, and grind them evenly to form a precursor;

[0047] Specifically, B is an element for doping and replacing Li, including any one or more of Na, K, Be, Mg, Ca, and Al; D is an element for doping and replacing C, including Si, B , any one or more of N, P, As, O, S;

[0048] Cold pressing the precursor to obtain a rough body of the precursor;

[0049] The rough billet is placed in a vacuum discharge plasma sintering device, and heat-treated at 600°C for 1 hour to obtain a coarse-grained ingot;

[0050] Pulverize the coarse-grained ingot in a glove box, then put it into a ball milling device, and perform high-energy ball milling to obtain a precursor powder;

[0051] The precursor powder was placed in a vac...

Embodiment 3

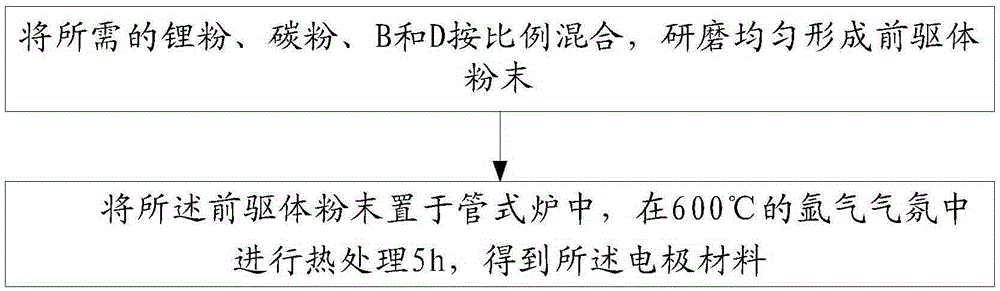

[0054] This embodiment provides a preparation method of an electrode material for a class of secondary batteries, specifically a solid-phase method, such as figure 2 shown, including:

[0055] Mix the required lithium powder, carbon powder, B and D in proportion, and grind them evenly to form a precursor powder;

[0056] Specifically, B is an element for doping and replacing Li, including any one or more of Na, K, Be, Mg, Ca, and Al; D is an element for doping and replacing C, including Si, B , any one or more of N, P, As, O, S;

[0057] The precursor powder was placed in a tube furnace, and heat-treated in an argon atmosphere at 600° C. for 5 hours to obtain the electrode material.

[0058] The method for preparing an electrode material for a secondary battery provided in this embodiment can be used to prepare the electrode material described in Embodiment 1 above. The method provided in this example is simple, the process is easy to control, and the synthesis temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cycle efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com