Eye and lip makeup remover and preparation method thereof

A make-up remover and a weight percentage technology, applied in the field of eye and lip make-up remover and its preparation, can solve the problems of inability to solve wrinkles on the skin of the eyes and lips, unsuitable for use on the eyes and lips, irritation of the skin of the eyes and lips, and the like. Gentle makeup removal, improved eye and lip lines, easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The Ulva extract in the present invention can be a commercially available product, or can be prepared by conventional methods. For example, the preparation method of Ulva extract of the present invention comprises the following steps:

[0036] Soaking Ulva seaweed crushed material in an alcohol aqueous solution to obtain a soaking solution;

[0037] The soaking liquid is subjected to microwave extraction to obtain liquid Ulva extract.

[0038] Specifically, the alcohol is 1,3-butanediol, and in the aqueous solution of the alcohol, the mass ratio of water to alcohol is 1:1-1:3, and the ground Ulva seaweed and 1,3-butane The solid-liquid ratio of the diol aqueous solution is 1:10-1:30.

[0039] Specifically, the soaking time is 4-10 hours, the microwave extraction time is 5-20 minutes, the microwave extraction temperature is 30-80°C, and the microwave extraction power is 200-1000W.

[0040] In addition, the liquid Ulva extract can be filtered and concentrated to obtain t...

Embodiment 1-10

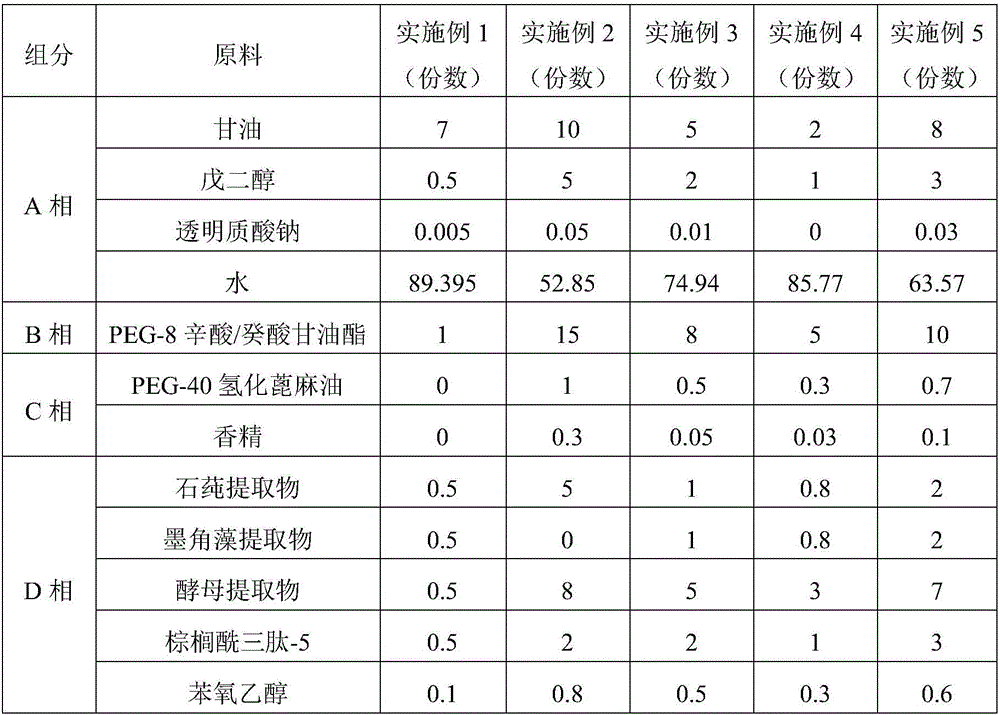

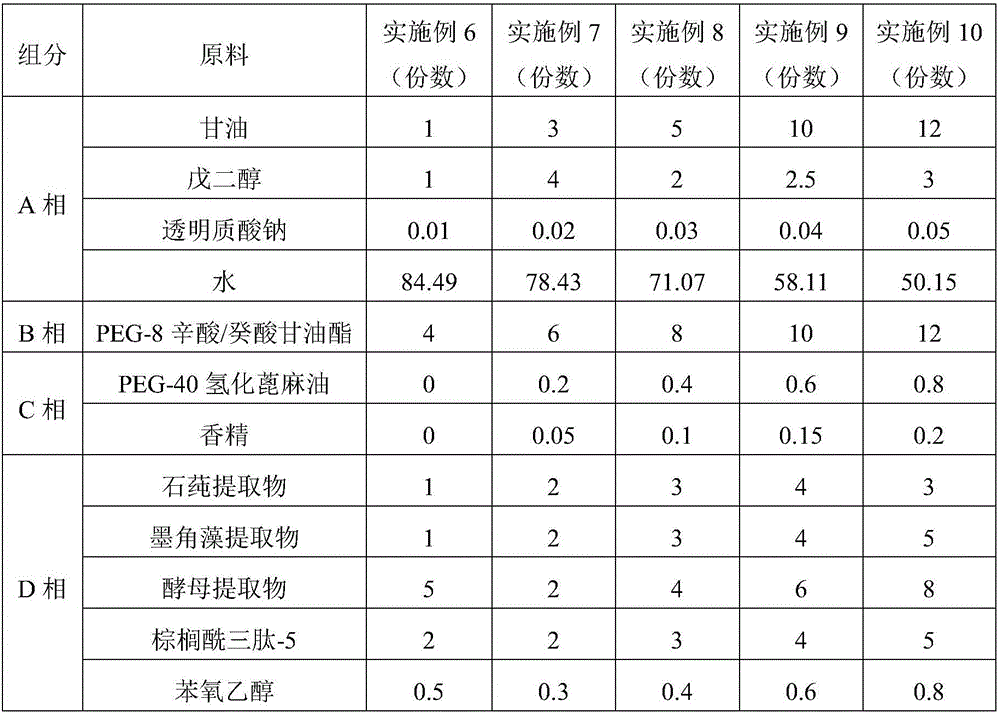

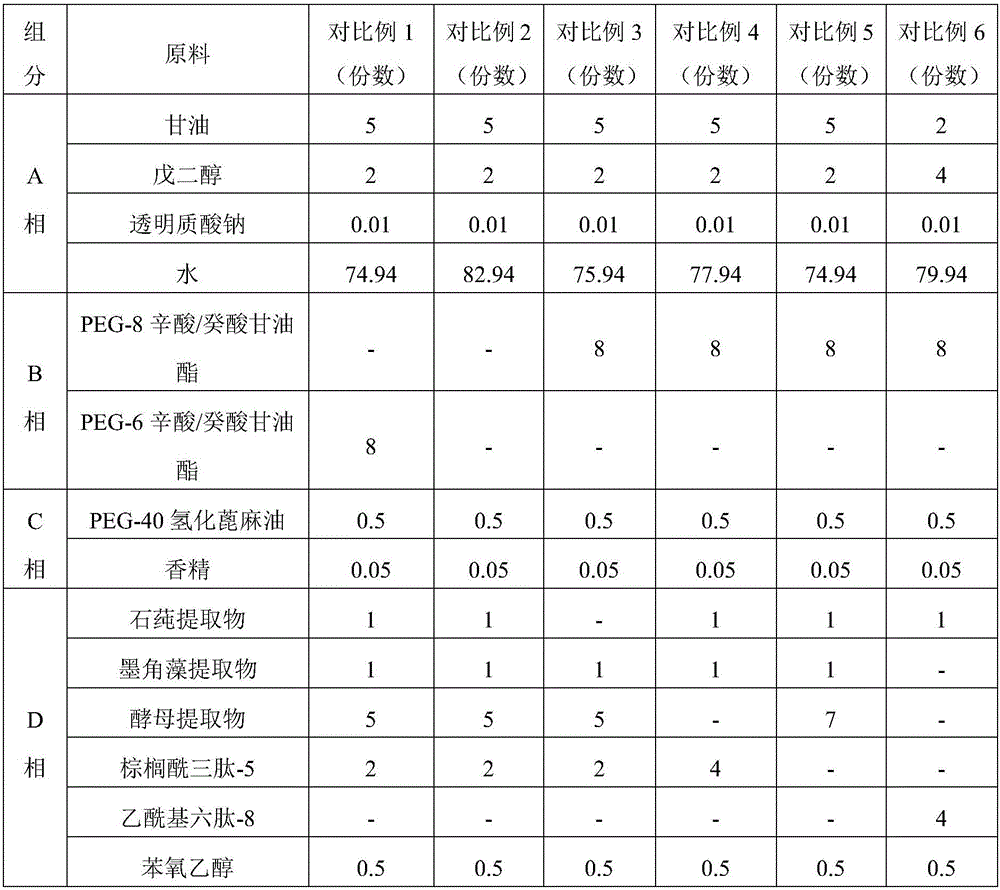

[0075] According to the content (number of parts) of each component in the following Table 1 and Table 2, and according to the following steps to prepare eye and lip cleansing water.

[0076] The preparation steps of eye and lip makeup remover are as follows:

[0077] (1) Add water into the emulsification pot, dissolve phase A (glycerin, pentylene glycol, sodium hyaluronate) in water, heat to 80°C, stir (35r / min) to dissolve completely, preferably use a homogenizer (2000r / min) to assist dissolution, and continue to insulate and stir (35r / min) for 10 minutes.

[0078] (2) Add phase B (PEG-8 caprylic acid / capric glyceride) into the emulsification pot, maintain the temperature at 80°C and continue stirring (35r / min) for 10 minutes, then cool down while stirring (35r / min).

[0079](3) Add phase C (PEG-40 hydrogenated castor oil and essence) into another reactor, stir (35r / min) and mix evenly, when the temperature of the emulsification pot drops to 45°C, add the mixed liquid, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com