Organic phase separation and recovery device and method capable of optimizing impurity filtering-out effect

A separation and recovery, organic phase technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of high operating cost, decreased output, large workload, etc., and achieve reliable operation, simple operation and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Further details will be given below in conjunction with the preferred embodiments shown in the accompanying drawings.

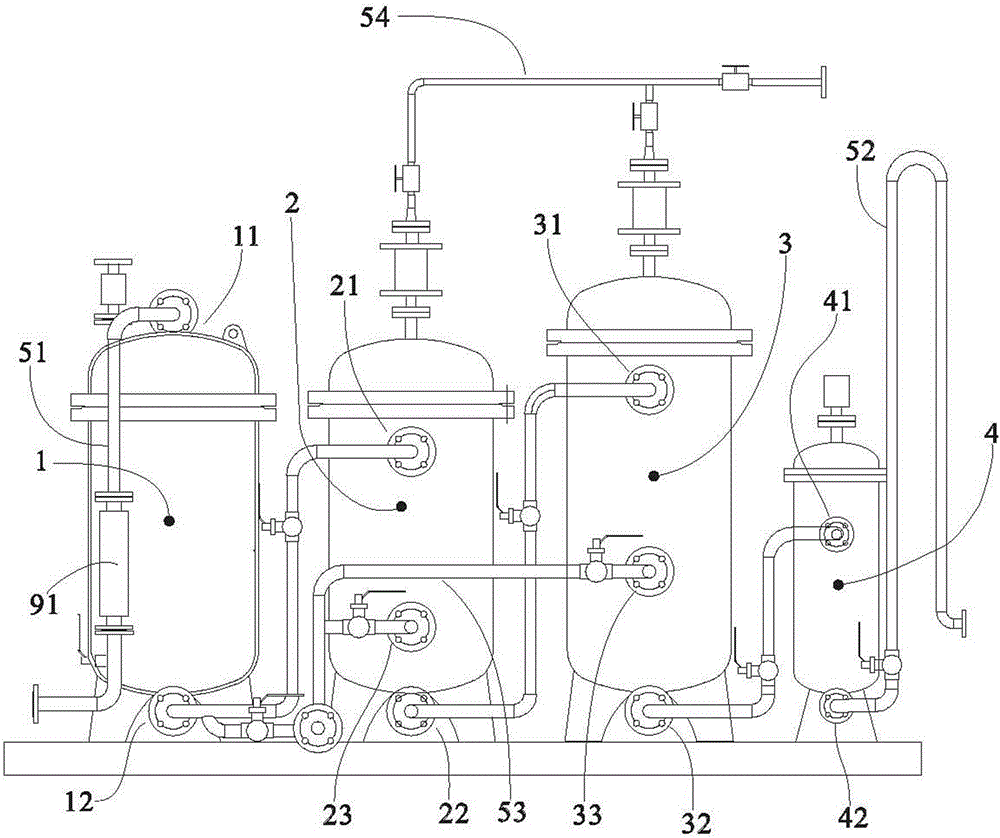

[0032] The present invention proposes an organic phase separation and recovery device that optimizes the filtering effect of impurities, such as figure 1 As shown, it includes a liquid inlet filter 1 for inputting and pre-filtering the organic phase mixture, a liquid discharge filter 4 for filtering and discharging the treated liquid, and a liquid inlet filter 1 and a liquid discharge filter 4 Between, at least two sequentially connected tank bodies, the preferred embodiment of the present invention selects two sequentially connected tank bodies 2,3. Both the inlet filter 1 and the outlet filter 4 are provided with PP filter cores. The PP filter element in the preferred embodiment of the present invention adopts a PP cotton high-precision filter element, which can remove suspended solids, colloids, activated carbon powder, etc. in the solution. Each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com