Kitchen garbage pretreatment system and method

A kitchen waste and pretreatment technology, applied to the removal of solid waste, etc., can solve the problems of low recovery rate of organic matter, broken bag of bagged garbage, low reduction rate, etc., and achieve high recycling rate and high-precision separation , The effect of high liquid phase purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

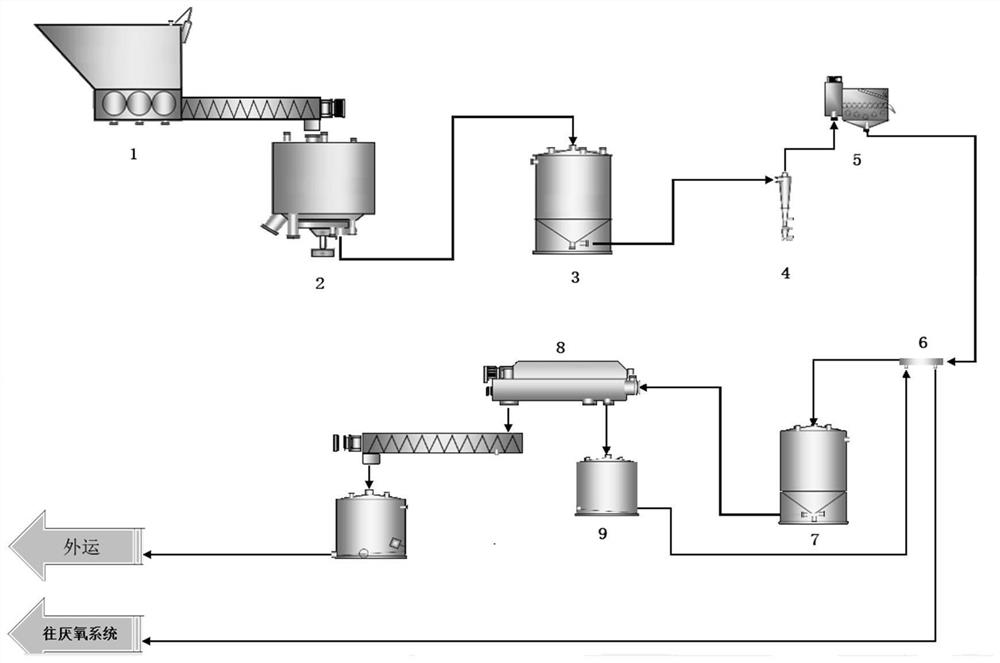

[0039] A kitchen waste pretreatment system (partial reference figure 1 ), including receiving hopper 1, pulper 2, discharge tank 3 (connected to pulper drain), high-concentration desander 4, sand-water separator 5, heat exchanger 6 (tube side) connected in sequence ), a sterilization tank 7, a two-phase centrifuge 8, a water buffer tank 9 (connected to the liquid phase outlet of the two-phase centrifuge), a heat exchanger 6 (shell side);

[0040] It also includes a screw press, the screw press is connected to the slag outlet of the pulper;

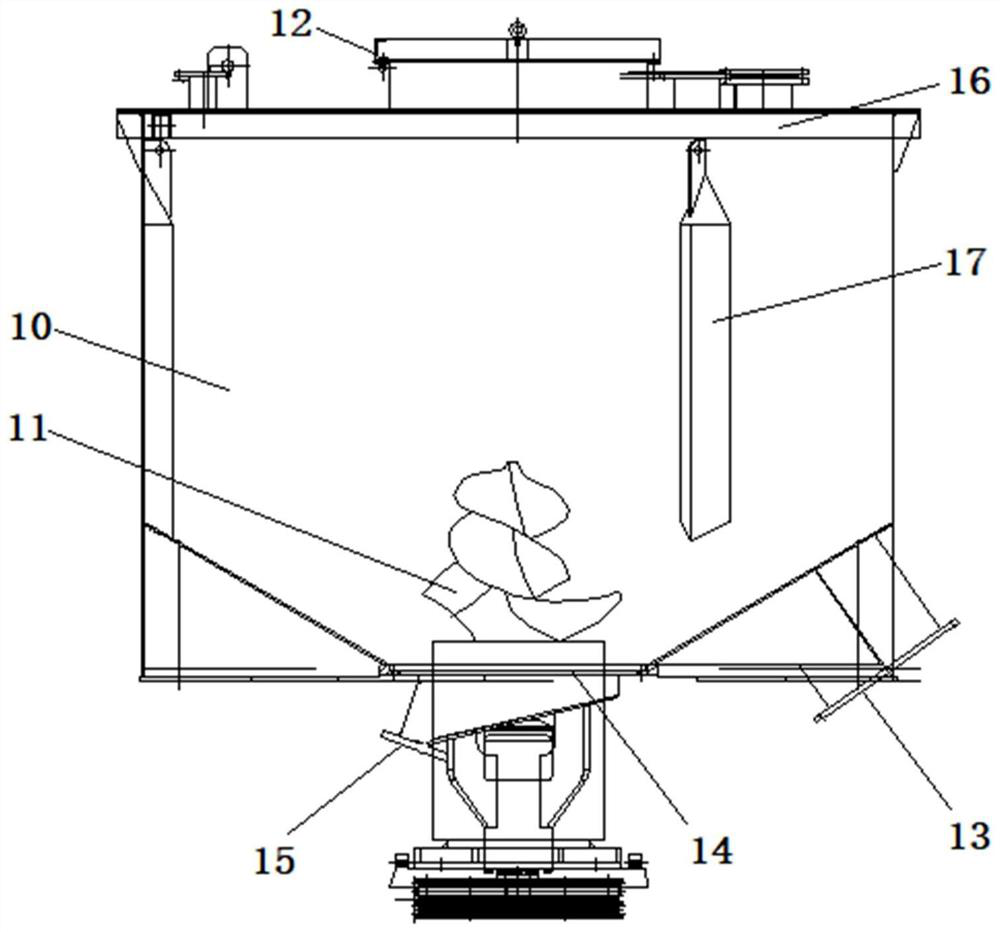

[0041] The pulper (partial reference figure 2 ) includes a pulping chamber 10, a rotor 11 arranged in the pulping chamber, a kitchen waste inlet 12 and a slag discharge port 13 arranged on the wall of the pulping chamber, and a A sieve plate 14 at the opening at the bottom of the body, and a drain port 15 is arranged below the sieve plate;

[0042] The rotor 11 is arranged vertically above the sieve plate, and it includes a rotating sh...

Embodiment 2

[0045]Using the system described in Example 1, the kitchen waste pretreatment is carried out according to the method of the present invention, which specifically includes the following steps:

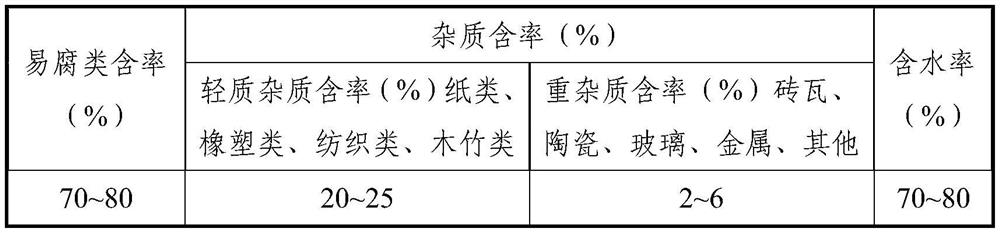

[0046] (1) Discharge the kitchen waste into the receiving hopper. Because it is classified as domestic waste, the moisture content is relatively low, and the size of the material is relatively large. There may be a lot of non- For perishable garbage, in order to ensure a smooth process, the material is loaded in the form of a grab bucket. The composition of the kitchen waste is shown in Table 1.

[0047] Table 1 Composition of kitchen waste

[0048]

[0049] (2) The kitchen waste is loaded from the receiving hopper to the pulper through a grab bucket (see Table 2 for equipment parameters), and industrial water is added to the pulper through the annular water spray pipe to adjust the solid content of the kitchen waste to 15%. , turn on the rotor to rotate for slurry treatment, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com