Kitchen waste pretreatment system and method

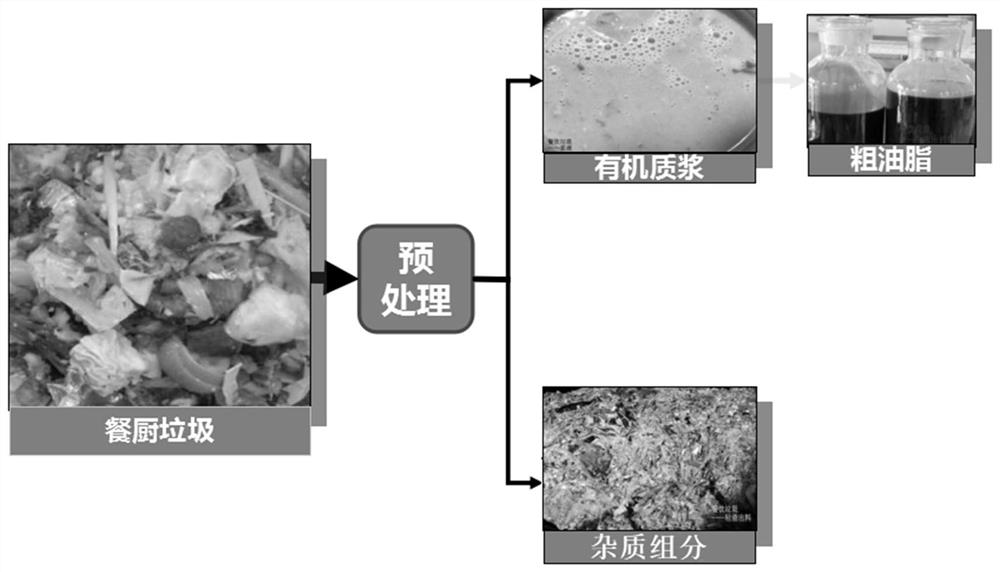

A food waste and pretreatment technology, which is applied in the direction of special treatment targets, anaerobic digestion treatment, chemical instruments and methods, etc., can solve the problems of low organic matter recovery rate, broken bags of bagged garbage, and difficulty in removing impurities, etc. High yield and oil phase yield, high recycling rate and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

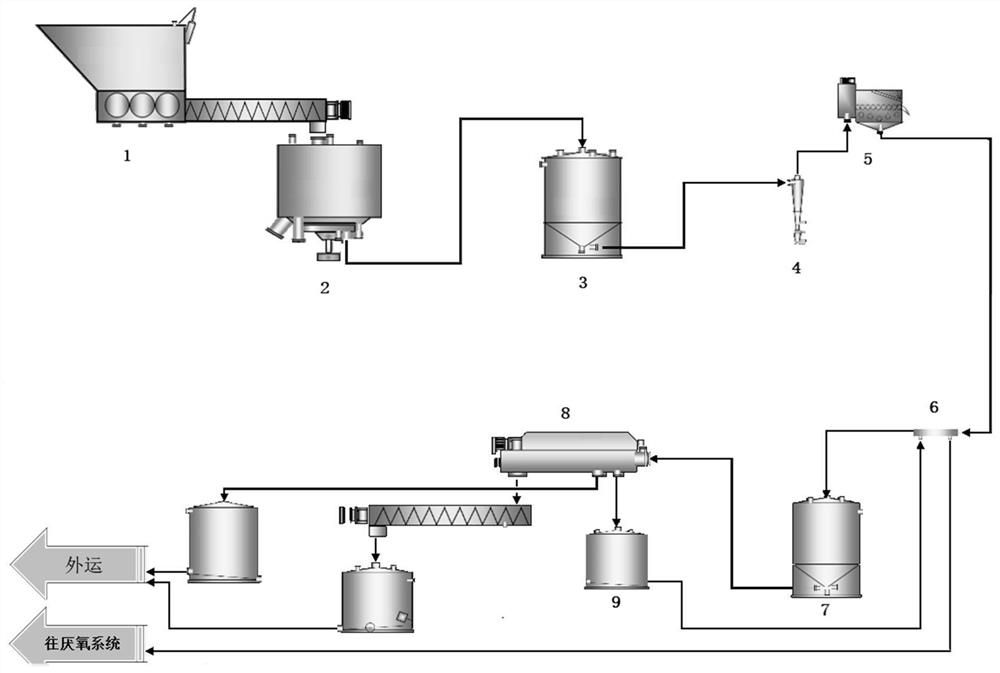

[0040] A kind of food waste pretreatment system (partial reference figure 1 ), including receiving hopper 1, pulper 2, discharge tank 3 (connected to pulper drain), high-concentration desander 4, sand-water separator 5, heat exchanger 6 (tube side) connected in sequence ), a sterilization tank 7, a three-phase centrifuge 8, a water buffer tank 9 (connected to the water phase outlet of the three-phase centrifuge), a heat exchanger 6 (shell side);

[0041] It also includes a screw press, the screw press is connected to the slag outlet of the pulper;

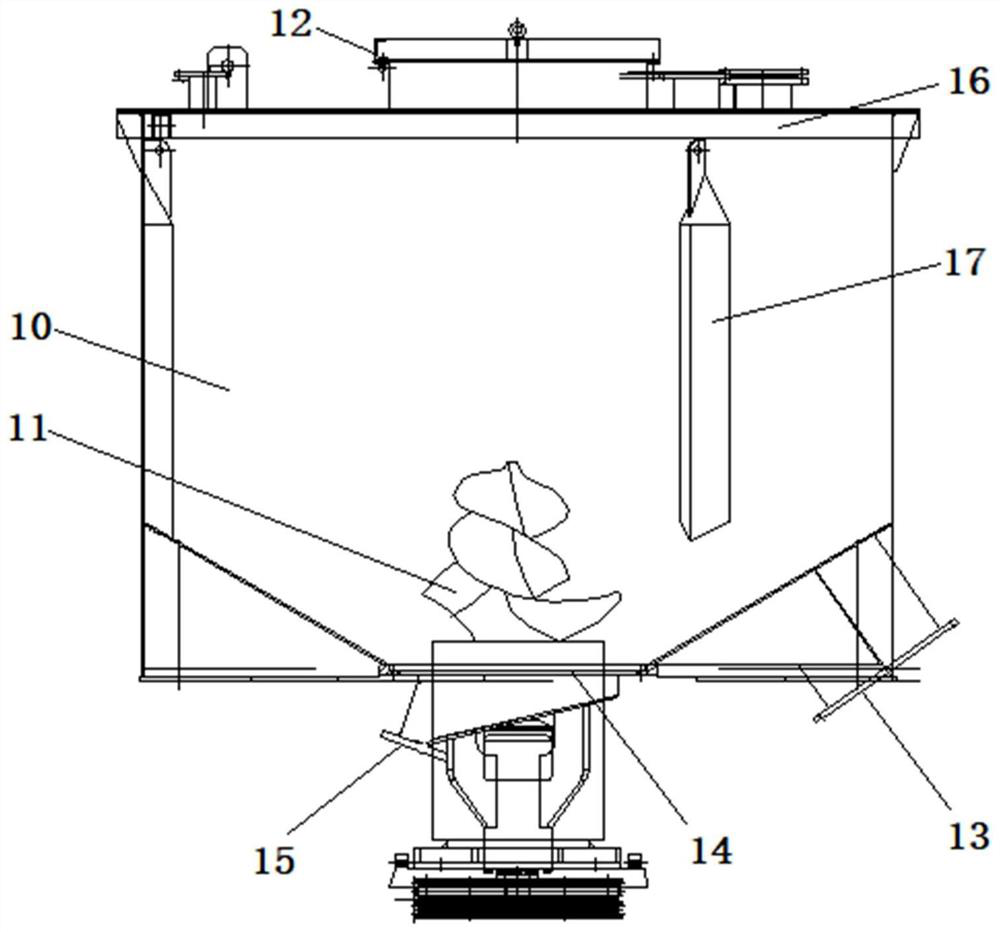

[0042] The pulper 2 (partial reference figure 2 ) includes a pulping chamber 10, a rotor 11 arranged in the pulping chamber, a food waste inlet 12 and a slagging outlet 13 arranged on the wall of the pulping chamber, and a A sieve plate 14 at the opening at the bottom of the body, and a drain port 15 is arranged below the sieve plate;

[0043] The rotor 11 is arranged vertically above the sieve plate, and it includes a rotating...

Embodiment 2

[0046] Adopt the system described in embodiment 1, carry out kitchen waste pretreatment according to the method of the present invention, specifically comprise the following steps:

[0047] (1) The food waste is discharged into the receiving hopper. The dry basis composition of the food waste is shown in Table 1, and the chemical composition table is shown in 2.

[0048] Table 1 Composition list of food waste (dry basis)

[0049]

[0050] Table 2 Chemical composition of food waste

[0051]

[0052] (2) The kitchen waste is conveyed to the pulper by the shaftless screw conveyor installed at the bottom of the receiving hopper (see Table 3 for equipment parameters), and industrial water is added to the pulper through the annular water spray pipe to adjust the solid content of the kitchen waste 6%, turn on the rotor to rotate for slurry treatment, the rotor allows the garbage flow to form a strong eddy current field, and within 3 to 5 minutes, the kitchen garbage is decompo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com