Separating and recycling method of rare earth elements

A rare earth element, separation and recovery technology, applied in the direction of improving process efficiency, can solve the problems of long time and expensive, and achieve the effect of simple technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

[0068] (Separation of rare earth elements from compounds containing rare earth elements)

[0069] Next, a method for separating and recovering rare earth elements from rare earth magnets (compounds of rare earth elements and other elements) that is an actual starting material at the time of separation and recovery using the above-mentioned principle will be described.

[0070] (Separation process of rare earth elements and other elements)

[0071] First, the procedure for obtaining a mixture of neodymium chloride and dysprosium chloride from rare earth magnet slag containing neodymium, dysprosium, iron, and boron as main components will be described. It should be noted that the actual rare earth magnet slag often contains praseodymium as another element of the rare earth elements, but since the physical and chemical properties of neodymium and praseodymium are very similar, it is considered here that praseodymium exists together with neodymium.

[0072] The separation process...

Embodiment 1

[0090] Experimental verification of separation and recovery from mixtures of rare earth chlorides. As a starting material for rare earth chlorides, anhydrous neodymium trichloride (NdCl 3 ) powder and anhydrous dysprosium trichloride (DyCl 3 )powder. As the powdered reagents used as starting materials, all 3N grade reagents manufactured by Kosun Chemical Research Institute Co., Ltd. were used. As the added metal M, fragments of metal yttrium (Y) (manufactured by Wako Pure Chemical Industries, Ltd., about 5×about 5×about 2mm 3 , purity 99.9%). In addition, since metal yttrium is easily oxidized by an oxygen source in the atmosphere, the metal yttrium stored in oil is prepared and used after removing the oil component immediately before use.

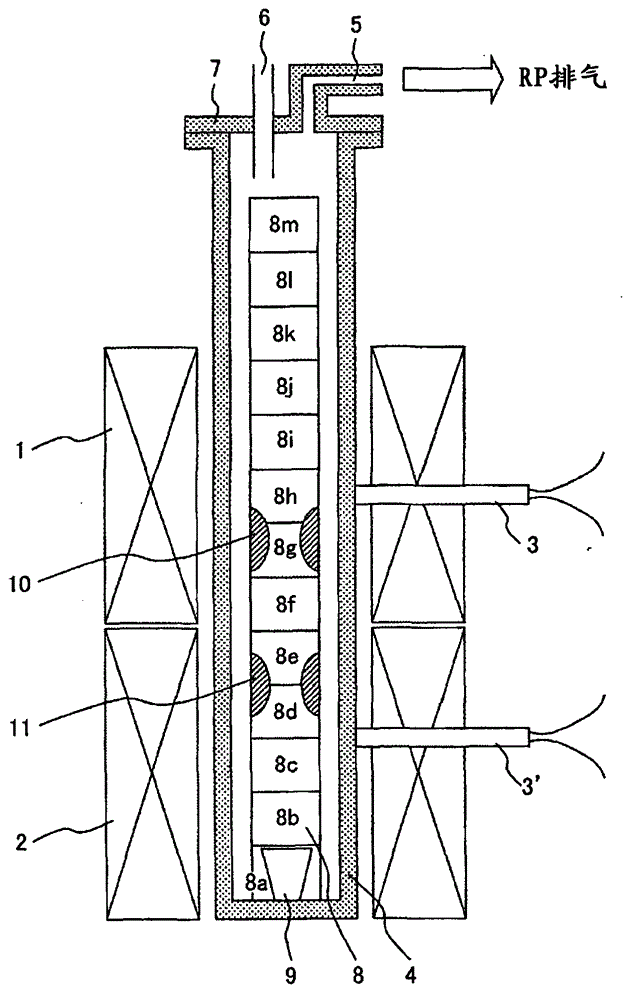

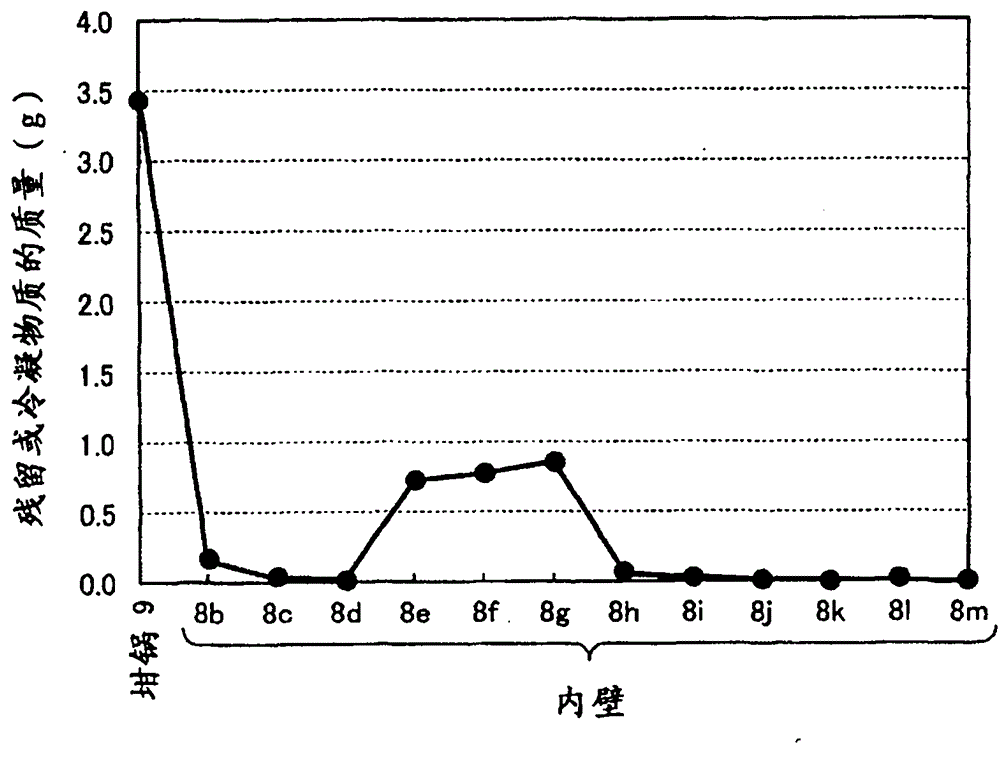

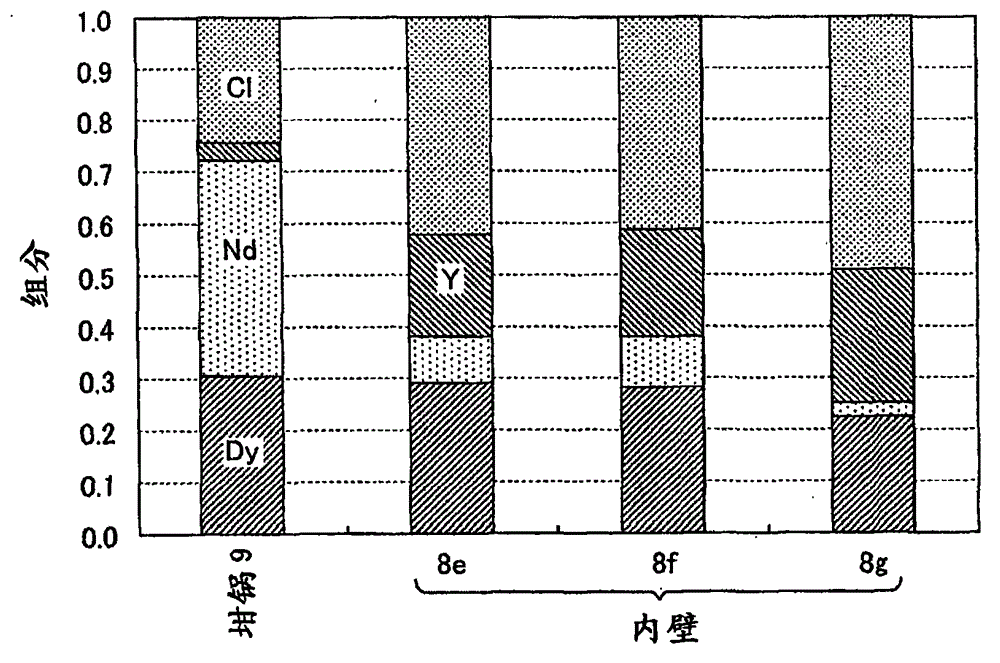

[0091] Weigh 2.5 g of NdCl in the drying chamber 3 powder, 2.5g of DyCl 3 The powder and 1.16 g of Y fragments were put into a crucible 9 made of molybdenum (Mo) and mixed. use figure 1 In the distillation apparatus 20 shown, a cru...

Embodiment 2

[0117] Research from rare earth magnets containing neodymium, dysprosium, praseodymium, iron, boron (RE 2 Fe 14 B. RE: Rare earth elements) Separation and recovery of rare earth elements from waste. The mass composition of the rare earth magnet used was 61.2%Fe-23.1%Nd-3.5%Dy-2.0%Pr-1.0%B. This scrap magnet is a defective product due to the occurrence of cracks, defects, etc. after nickel plating was performed in the manufacturing process.

[0118] First, coarse crushing of scrap magnets was performed by heating at 800°C in a hydrogen atmosphere using an electric furnace. As mentioned above, although nickel plating is performed on this scrap magnet, the nickel plating film can be peeled off by the hydrogen crushing process, and the peeled plating film can be separated from the magnet powder by the sieving method.

[0119] The obtained magnet powder was mixed with FeCl as chlorine source 2 The powder is mixed, then joins in the iron crucible 9, configures in figure 1 Insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com