A one-time molding mold specially used for side panels of safes

A technology for forming molds and safes, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult processing, low processing accuracy, poor efficiency, etc., to avoid sheet material offset, high bending positioning accuracy , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

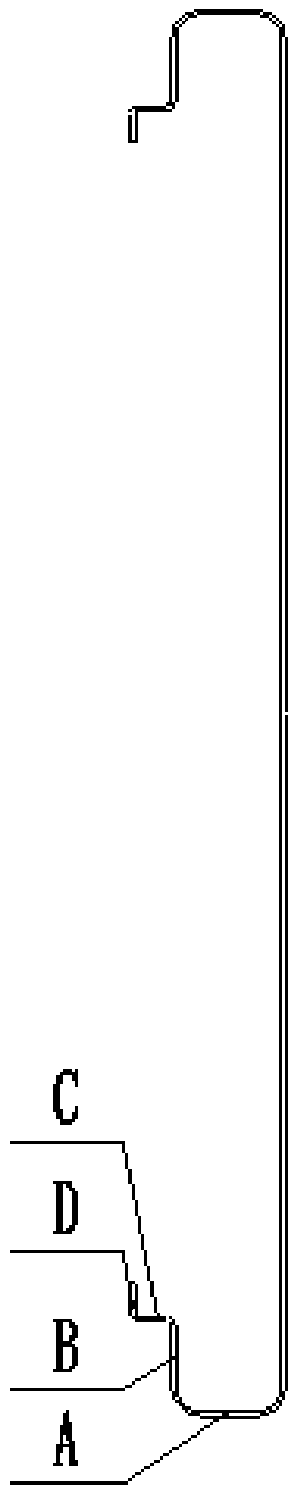

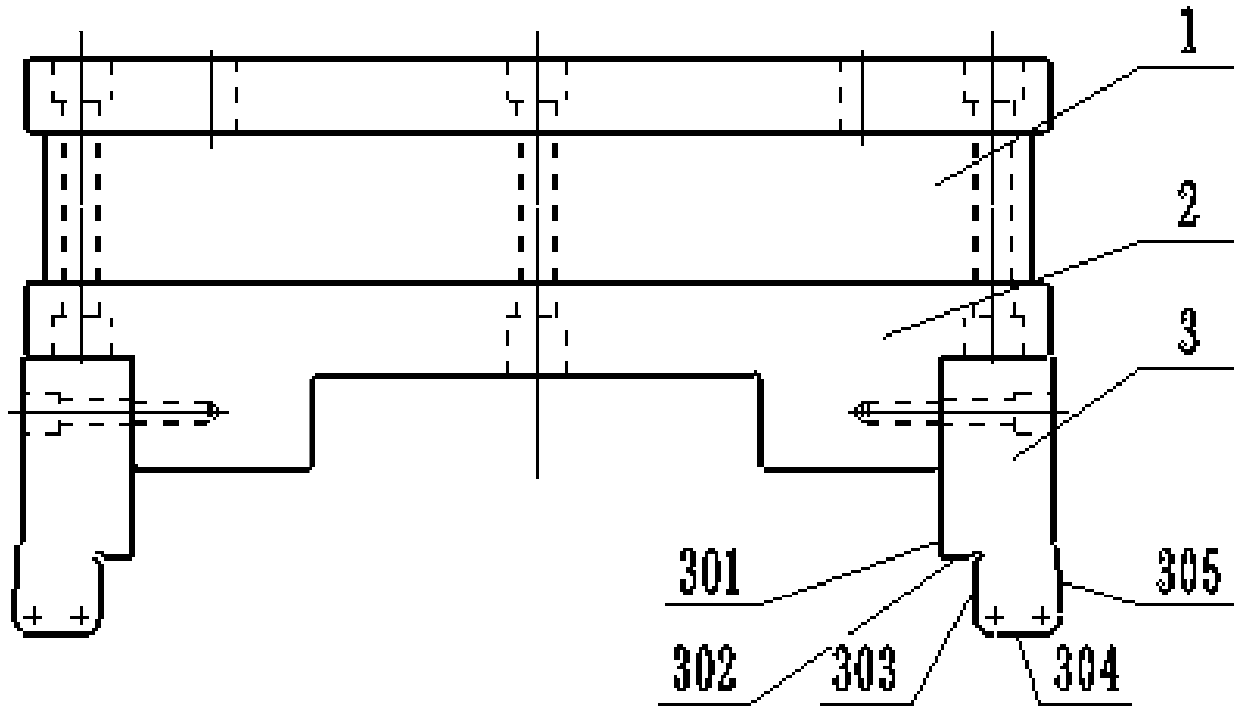

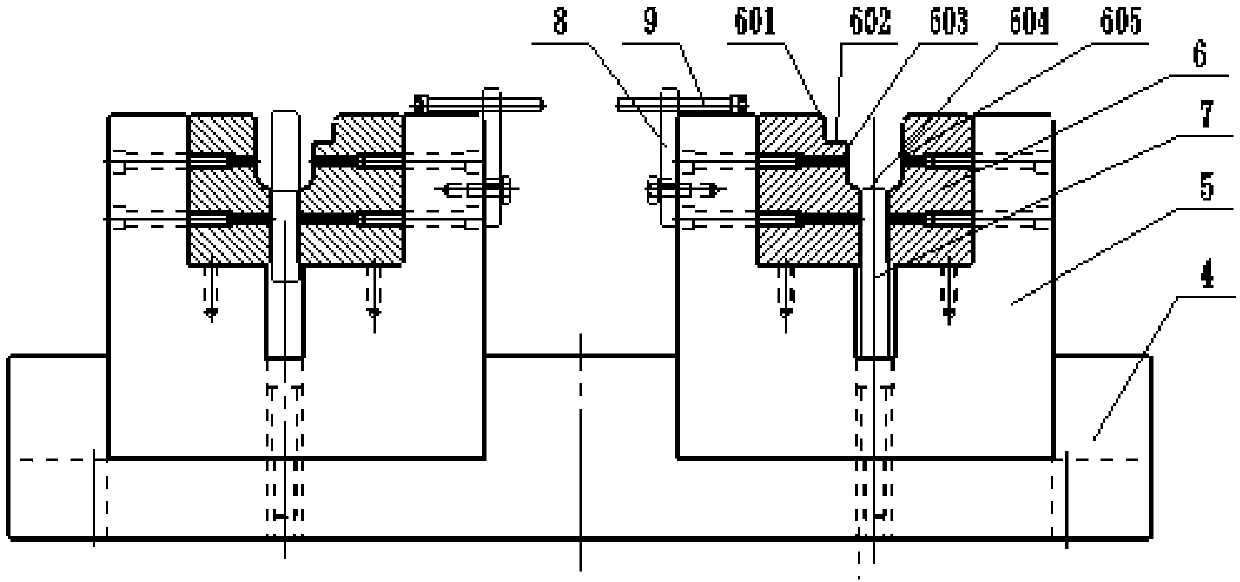

[0059] Such as figure 2 , image 3 As shown, a one-time forming mold for a side plate of a safe in this embodiment includes an upper mold assembly and a lower mold assembly; wherein, the upper mold assembly includes an upper mold base 1 and an upper mold 3, and the upper mold base 1 is The upper mold fixed block 2 is installed, and the upper mold 3 has two, and the two upper molds 3 are symmetrically arranged on the left and right ends of the upper mold fixed block 2 respectively; and the upper mold 3 is fixed on the upper mold fixed block 2 groove, and is detachably connected to the upper mold fixing block 2 by bolts, and the design of the upper mold fixing groove makes the installation of the upper mold 3 convenient and accurate in positioning. The lower end of the upper die 3 is a stamping end, which is composed of a first vertical surface 301, a first horizontal surface 302, a second vertical surface 303, a second horizontal surface 304 and an inclined surface 305 from o...

Embodiment 2

[0078] Although the mold and method in Example 1 can be used to complete the bending process of the side plate of the safe, there is a problem, that is, the number of times of use is too large, and the working parts of the upper mold 3 and the lower mold 6 are due to greater force. , easily damaged, resulting in the need to replace the mold after a period of use. It has been proved by practice that the upper mold processed by ordinary materials and heat treatment processes will easily appear between the second vertical surface 303 of the upper mold 3 and the second vertical surface 303 when it is used for about 2300 times. The junction of the two horizontal planes 304 and the junction of the second horizontal plane 304 and the inclined surface 305 appear cracks and abrasions. Similarly, the junctions of the first transverse groove surface 602 and the second vertical groove surface 603 also appear cracks and abrasions. Although the above factors have been considered in the struc...

Embodiment 3

[0093] A kind of processing method of special bending mold for safe door frame plate of the present embodiment, lower mold 6 is processed, and its steps are:

[0094] (1) Raw material preparation for rough

[0095] It is made by forging blank. The composition and mass percentage of the forging blank are: C 0.4%, Si 0.3%, Mn0.65%, S ≤ 0.023%, P ≤ 0.021%, Cr 1.4%, Mo 0.42%, ZrO 2 0.1%, the balance is Fe;

[0096] (2) Annealing treatment of forging blank

[0097] Anneal the forged blank obtained in step (1) through an annealing furnace, the annealing temperature is 810°C, the annealing time is 3.5 h, cool to 250°C in the annealing furnace, hold for 0.8h, and then air cool to room temperature;

[0098] (3) Initial processing of forging blanks

[0099] Process the forged blank in step (2) into the primary shape of the mold on the machine tool, leaving a margin of 1.5mm on each side;

[0100] (4) Heat treatment of the mold

[0101] The mold obtained by machining in step (3) wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com