Double-beam laser deep penetration brazing method applicable to moderately thick plate aluminum/steel dissimilar alloy connection

A brazing method and double-beam technology, applied in the direction of welding/welding/cutting articles, welding equipment, metal processing equipment, etc., to achieve the effect of improving wetting and spreading, inhibiting the formation of brittle intermetallic compounds, and high-quality connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

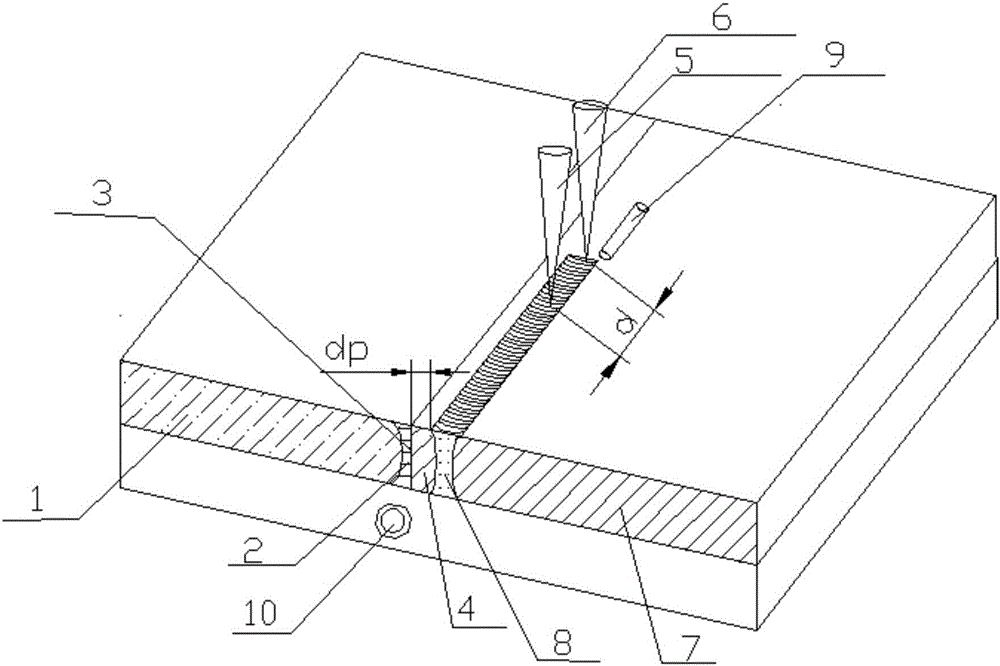

Method used

Image

Examples

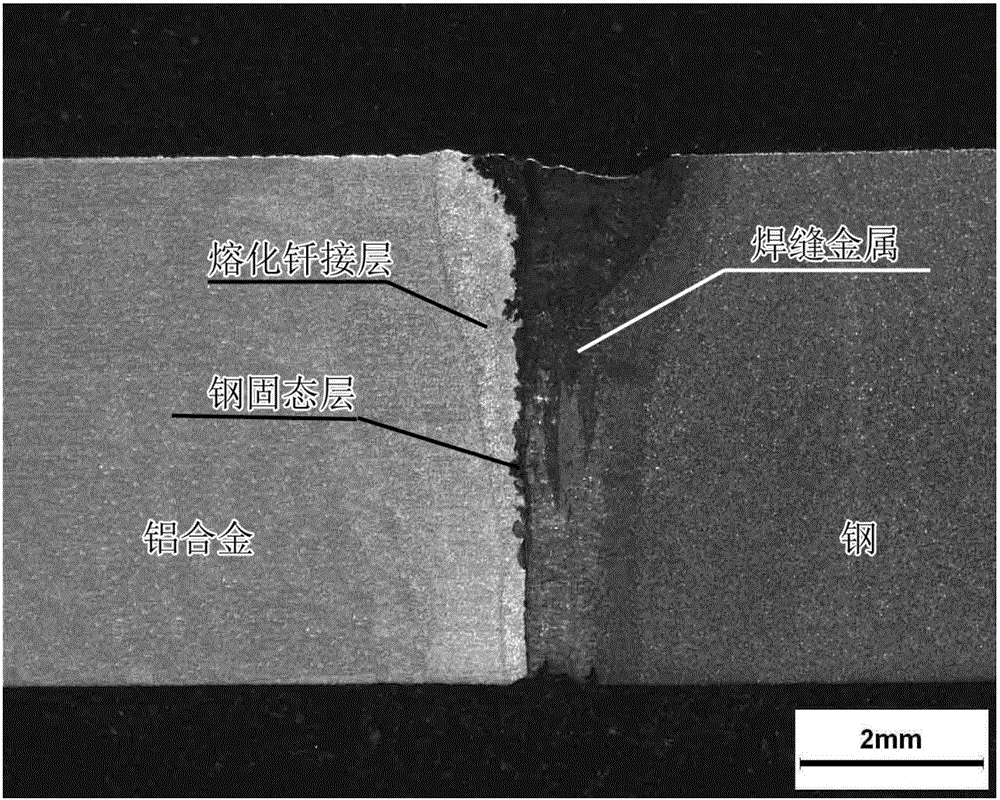

example 1

[0022]Example 1: The YLS-6000 fiber laser produced by IPG is used, the laser wavelength is 1070nm, the offset of the double-beam laser from the steel and aluminum interface layer is 0.6mm, the welding speed is 1.0m / min, and the defocus is 0mm. Dual-beam lasers are focused on one side of the steel plate. The base metal used in the test is 6mm 5083 marine aluminum alloy plate and 6mm thick Q235 steel plate, and the sample size is 150mm. The total power of the double-beam laser is 3250W, and the energy ratio of the two beams is 250W:3000W. figure 2 It is a welding example diagram of pre-welding pretreatment with low power. It can be found that the interface between aluminum and steel is flush. The inhomogeneity of the intermetallic compound in some areas of the interface is improved, and the thickness of the intermetallic compound is 5.02 μm, which effectively inhibits the growth of the intermetallic compound. The hardness value between the interfaces is 714.6HV, which effect...

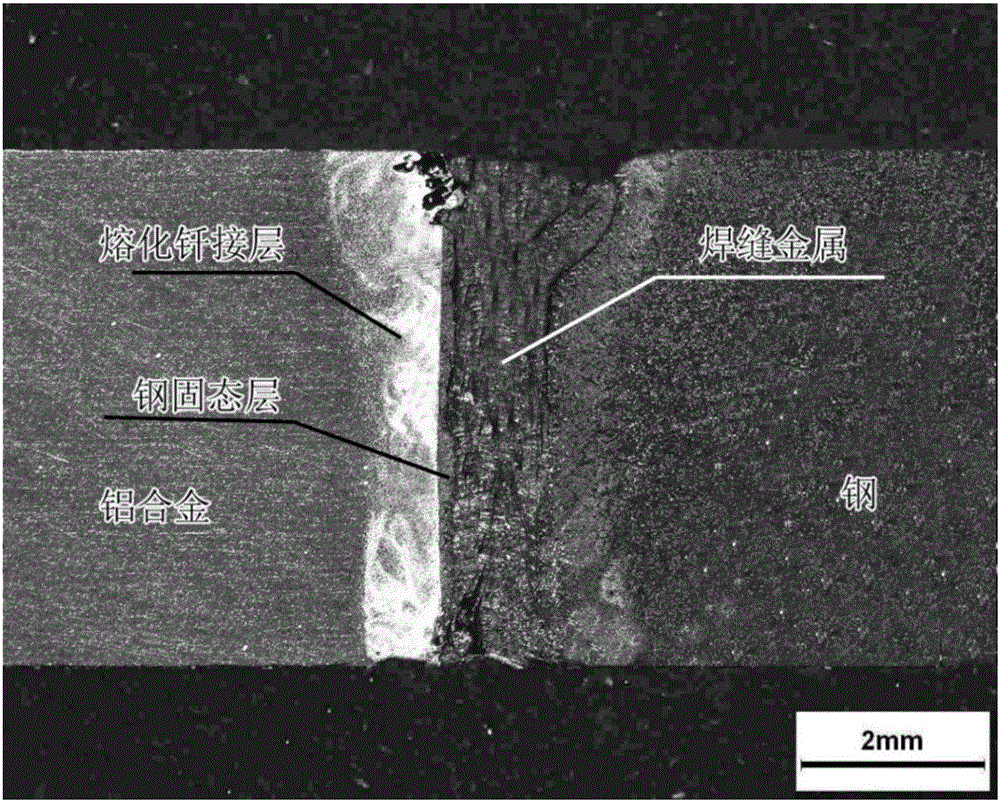

example 2

[0023] Example 2: Using YLS-6000 fiber laser produced by IPG Company, the laser wavelength is 1070nm, the offset of the double beam laser from the steel and aluminum interface layer is 0.6mm, the welding speed is 1.0m / min, and the defocus is 0mm. Dual-beam lasers are focused on one side of the steel plate. The base metal used in the test is 6mm 5083 marine aluminum alloy plate and 6mm thick Q235 steel plate, and the sample size is 150mm. The total power of the double-beam laser is 3250W, and the energy ratio of the two beams is 250W:3000W. The test uses a low-power laser to perform post-weld heat treatment after welding. image 3 Its welding example diagram. It can be found that when the post-weld heat treatment is performed with low power, the weld seam is well formed, the amount of liquid aluminum alloy is increased, and the brazing quality is improved by prolonging the wetting and spreading time of aluminum alloy. The intermetallic compound is relatively uniform, the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com