Anti-aging elastomer-modified asphalt waterproof rolling material

A kind of asphalt waterproof membrane and body modification technology, which is applied in the direction of asphalt layered products, building insulation materials, chemical instruments and methods, etc., can solve the problems of loss of waterproof effect, poor anti-aging effect, and easy aging, and achieve anti-aging Improve peelability and weather resistance, improve anti-aging ability, and slow down the effect of aging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

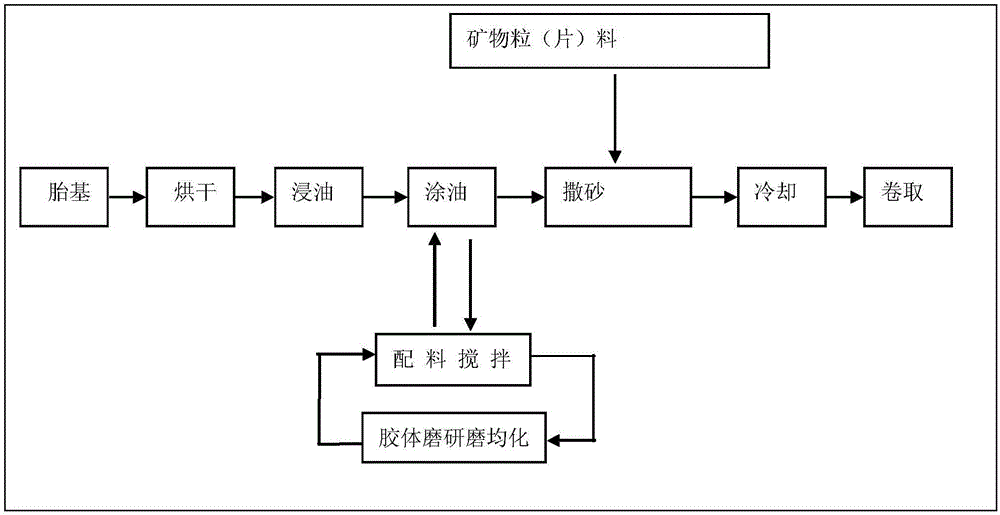

Method used

Image

Examples

Embodiment 1

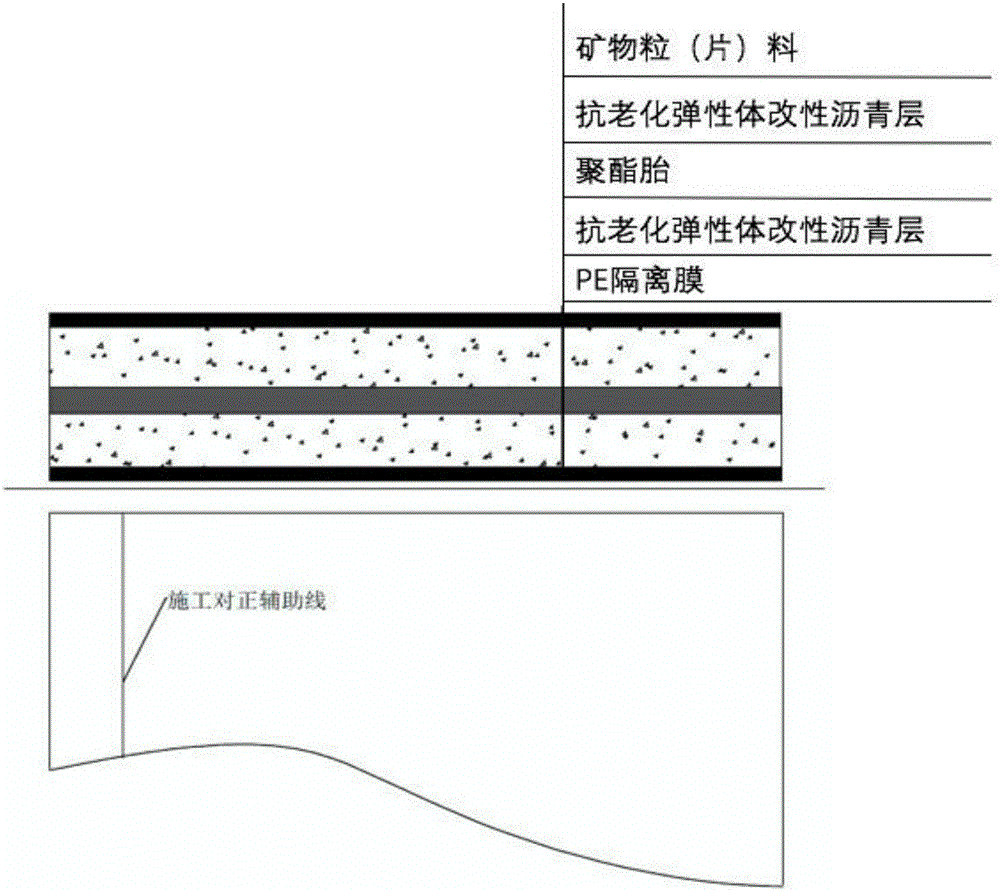

[0027] Polyester tire specification is 200g / m 2 , The thickness is 1.2mm; the thickness of the mineral granular material layer is 0.8mm, the thickness of the upper and lower anti-aging elastomer modified asphalt layers are each 1.0mm, and the lower surface isolation film layer is 0.2mm.

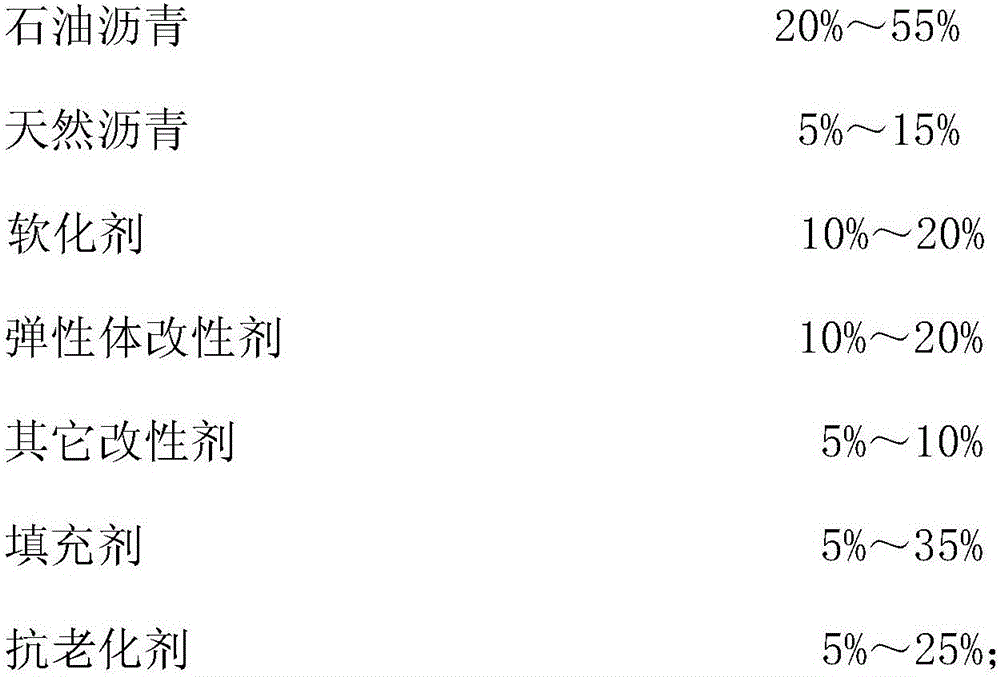

[0028] The chemical composition of the anti-aging elastomer modified asphalt is as follows:

[0029]

[0030]

[0031] In the ultraviolet aging test box (ultraviolet intensity 0.68W / m 2 , The temperature is 60℃, the time is 7 days, the same below) Anti-aging elastomer modified asphalt, the anti-aging elastomer modified asphalt waterproofing membrane is aged in the heat aging test box (80℃, 10 days, the same below) test.

[0032] After the UV aging test, the softening point of the anti-aging elastomer modified asphalt with attapulgite was increased from 117°C to 122°C, an increase of 5°C, but the anti-aging effect of the attapulgite was not added The softening point of elastomer modified asphalt inc...

Embodiment 2

[0036] Polyester tire specification is 180g / m 2 , The thickness is 0.8mm; the thickness of the mineral granular material layer is 0.8mm, the thickness of the upper and lower anti-aging elastomer modified asphalt layers is 1.2mm, and the lower surface isolation film layer is 0.2mm.

[0037] The chemical composition of the anti-aging elastomer modified asphalt is as follows:

[0038]

[0039] After the UV aging test, the anti-aging elastomer modified asphalt with attapulgite has its softening point increased from 120℃ to 124℃, an increase of 4℃, without adding attapulgite for aging resistance The softening point of elastomer modified asphalt increased from 103°C to 111°C, an increase of 8°C;

[0040] After the heat aging test of the anti-aging elastomer modified asphalt waterproofing membrane, the low temperature flexibility of the anti-aging elastomer modified asphalt waterproofing membrane added with attapulgite was reduced from -25°C to -20°C, a decrease of 5°C. However, the low te...

Embodiment 3

[0043] Polyester tire specification is 200g / m 2 , The thickness is 1.2mm; the thickness of the mineral granular material layer is 0.8mm, the thickness of the upper and lower anti-aging elastomer modified asphalt layers is 1.1mm each, and the lower surface isolation film layer is 0.2mm.

[0044] The chemical composition of the anti-aging elastomer modified asphalt is as follows:

[0045]

[0046] After the UV aging test, the softening point of the anti-aging elastomer modified asphalt with attapulgite increased from 116°C to 122°C, an increase of 6°C without adding attapulgite The softening point of elastomer modified asphalt has increased from 100°C to 111°C, an increase of 11°C;

[0047] After the heat aging test, the low-temperature flexibility of the anti-aging elastomer-modified asphalt waterproofing membrane added with attapulgite was reduced from -25°C to -21°C, a drop of 4°C. However, the low-temperature flexibility of the anti-aging elastomer modified asphalt waterproofing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Uv intensity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com