High-performance tripod head

A high-performance, pan-tilt technology, applied in the field of high-performance pan-tilt, can solve the problems such as inability to effectively eliminate jitter, large torque fluctuation of pan-tilt motor, affecting pan-tilt imaging effect, etc., to improve imaging effect and high operating efficiency. , start the smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

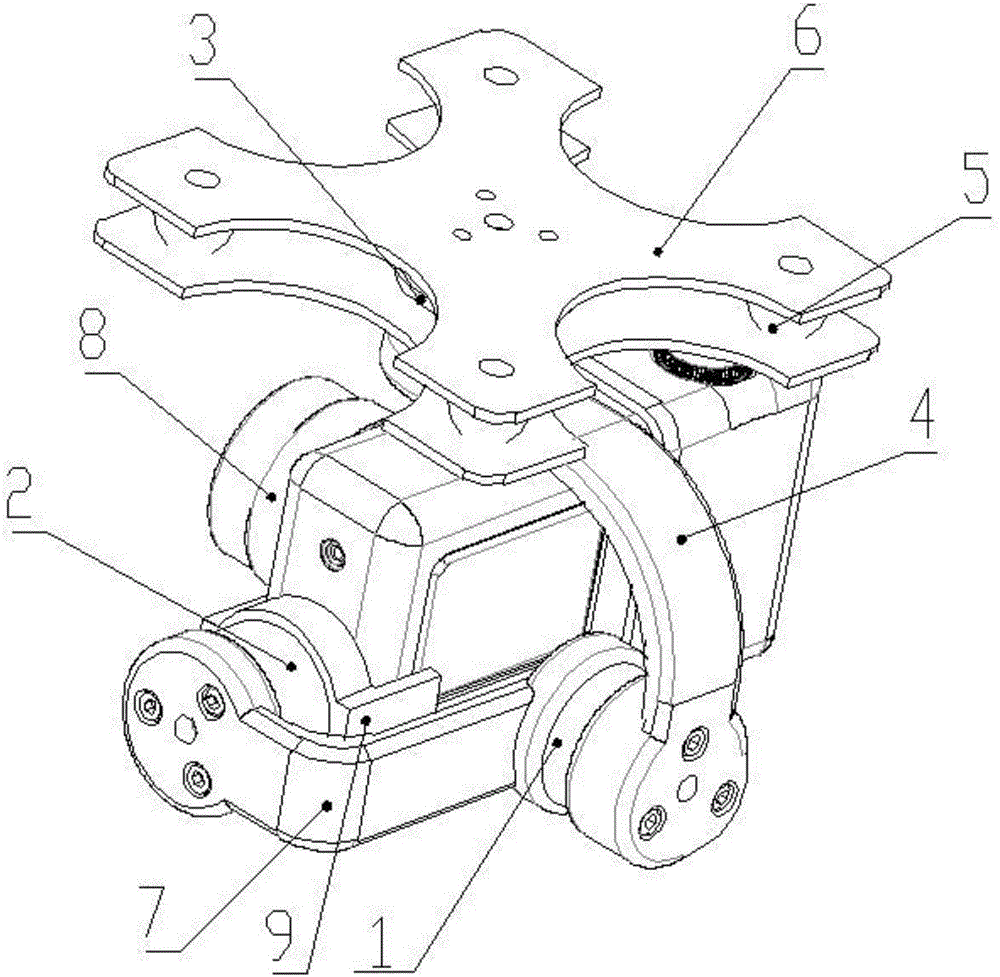

[0051] refer to Figure 1 ~ Figure 3 , the high-performance pan-tilt provided in this embodiment is used for aerial photography, and the high-performance pan-tilt includes a pan-tilt motor 100, a pan-tilt bracket 6 connected to one end of the pan-tilt motor 100 and a camera 8 connected to the other end of the pan-tilt motor 100;

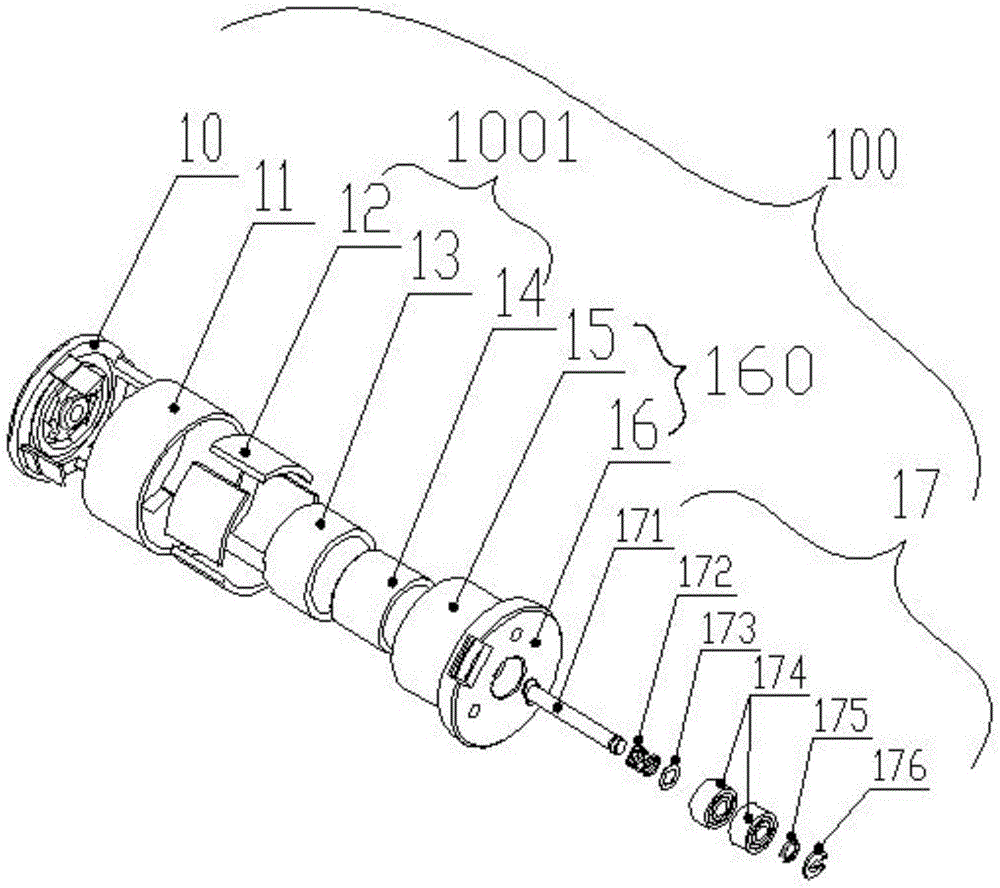

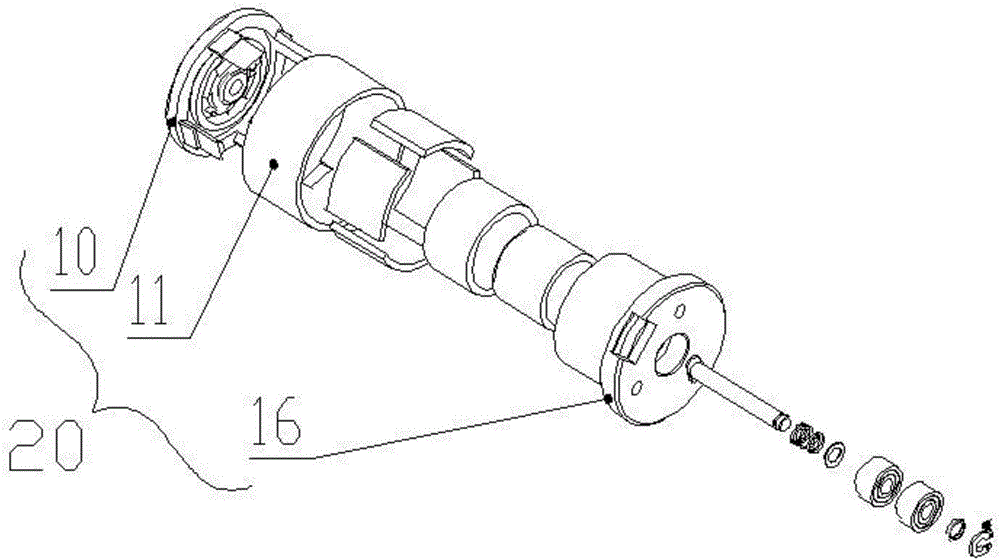

[0052]The pan / tilt motor 100 includes a casing 20, a stator assembly 160 disposed in the casing 20, a rotor assembly 1001 coaxially arranged with the stator assembly 160, and a shaft system passing through the center of the stator assembly 160 and the rotor assembly 1001 from one end of the casing 20 Part 17;

[0053] Wherein, the casing 20 includes a front cover 10 and an outer cover 11 connected to the front cover 10;

[0054] The rotor assemblies 1001 are all ring-shaped, and the rotor assembly 1001 includes: an outer magnet 12 arranged close to the inner wall of the outer cover 11, an inner magnet 13 arranged in the inner ring of the outer magne...

Embodiment 2

[0061] refer to Figure 2 ~ Figure 4 The difference from the above embodiment is that, preferably, the center of the front cover 10 is provided with a groove 102, and the outer ring of the groove 102 is provided with an inner yoke mounting hole 103, an outer magnet slot 101 and an outer surface of the front cover 10. There are claws 104 between the diameters;

[0062] Among them, the groove 102 is connected with one end of the shafting part 17, the inner yoke installation hole 103 is interference fit with the inner yoke 14, the claw 104 is connected with the groove 111 provided on the outer cover 11, and the claw 104 is connected with the groove 111 Fastened by glue, the outer magnet 12 is arranged between two adjacent jaws 104 and fastened by glue.

[0063] The inner wall of the outer cover 11 has a slot 111 to cooperate with the claw 104 of the front cover 10, and further tighten the connection by gluing, which can effectively prevent loosening and circumferential slipping....

Embodiment 3

[0073] like figure 1 As shown, the difference from the above-mentioned embodiment is that, preferably, the pan-tilt bracket 6 is a composite structure, and shock-absorbing balls 5 are provided on the corners of the pan-tilt bracket 6 .

[0074] Preferably, there are three pan-tilt motors 100, which are the pan-axis pan-tilt motor 3 arranged at the top of the camera 8, the pitch-axis pan-tilt motor 2 arranged on the side of the camera 8, and the roll-axis pan-tilt motor arranged at the rear end of the camera 8. motor 1;

[0075] One end of the pitch axis gimbal motor 2 is connected to the camera 8 through the camera mount 9, and the other end is connected to the roll axis gimbal motor 1 through the second connecting arm 7;

[0076] The pan-tilt motor 1 of the roll axis is connected to the pan-tilt motor 3 through the first connecting arm 4, one end of the pan-tilt motor 3 is connected to the first connecting arm 4, and the other end of the pan-tilt motor 3 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com