Plunger type coal ash pressurized conveying device

A conveying device and plunger type technology, which is applied in the field of plunger type pulverized coal pressurized conveying devices, can solve the problems of high valve sealing and pressure resistance requirements of pulverized coal pipelines, low efficiency in the conveying process, and inability to continuously adjust, etc. Go to automatic control, light weight, reduce the effect of pulverized coal pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

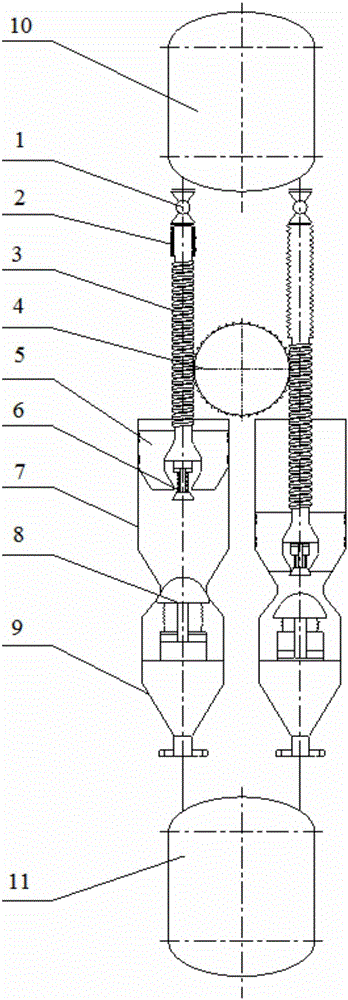

[0037] like figure 1 A schematic structural diagram of a plunger-type pulverized coal pressurized conveying device provided by an embodiment of the present invention, as shown in figure 1 As shown in , the device includes: a driving part 4 and two conveying passages arranged in parallel; the upper and lower ends of the conveying passage are respectively connected with the atmospheric pressure storage tank 10 and the pulverized coal feeding tank 11; the conveying passage includes a normal Press feed valve 1, retractable pulverized coal conveying pipeline 2, worm pulverized coal conveying pipeline 3, piston part 5, pulverized coal feed valve 6, pulverized coal conveying chamber 7, pulverized coal discharge valve 8, and discharge section 9; Among them, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com