Fully-automatic waste recycling device of intelligent coal sampling machine

A recycling device and sample making machine technology, which is applied to conveyors, loading/unloading, transportation and packaging, etc., can solve the problems that the safety of discarded samples cannot be effectively controlled, automatic recycling cannot be realized, and the cost of conveyor belt equipment is high. , to achieve the effect of small footprint, less maintenance work and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

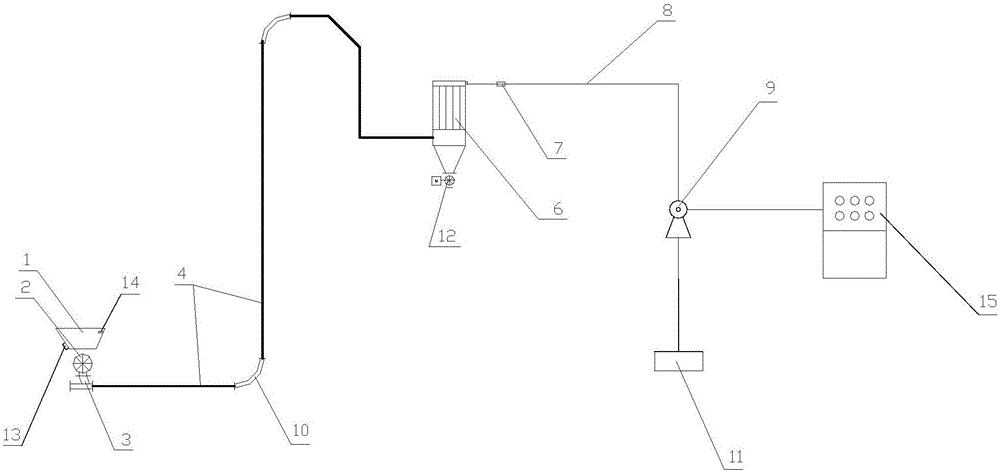

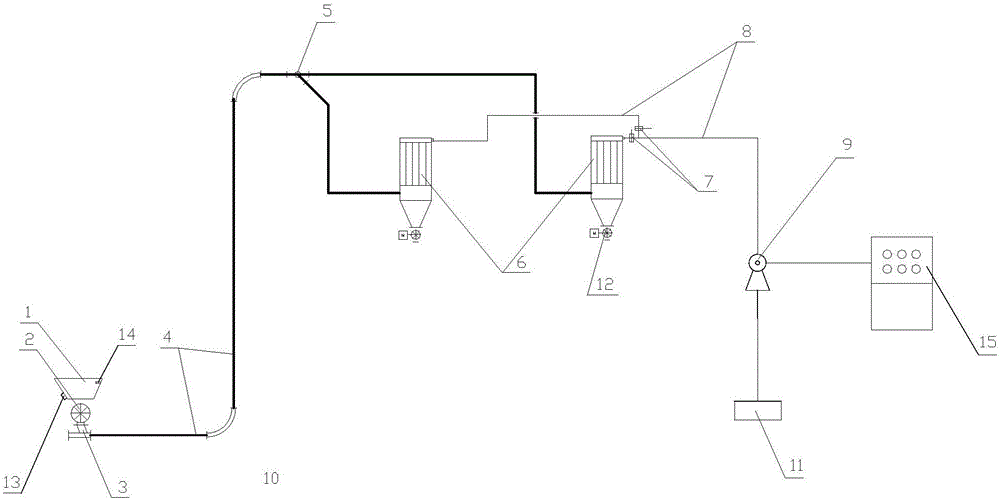

[0021] The following will be combined with figure 2 , 3 The present invention is further described.

[0022] The present invention consists of a hopper 1, a rotary feeder 2, an acceleration chamber 3, a material transmission pipeline 4, a pneumatic shunt valve 5, a combined material-gas separator 6, a pneumatic butterfly valve 7, a gas delivery pipeline 8, a Roots vacuum pump 9, and an elbow 10. Program control system 11, rotary unloader 12, waste material collection valve 13, material level gauge 14. The specific structure is the same as that described in Embodiment 1. There are two combined material and gas separators 6, which are respectively connected to material transmission Pipeline 4, and a pneumatic shunt valve 5 is provided on the material transmission pipeline 4. At the same time, two combined material gas separators 6 are respectively connected to two gas delivery pipelines 8, and a pneumatic butterfly valve 7 is respectively installed on the two gas delivery pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com